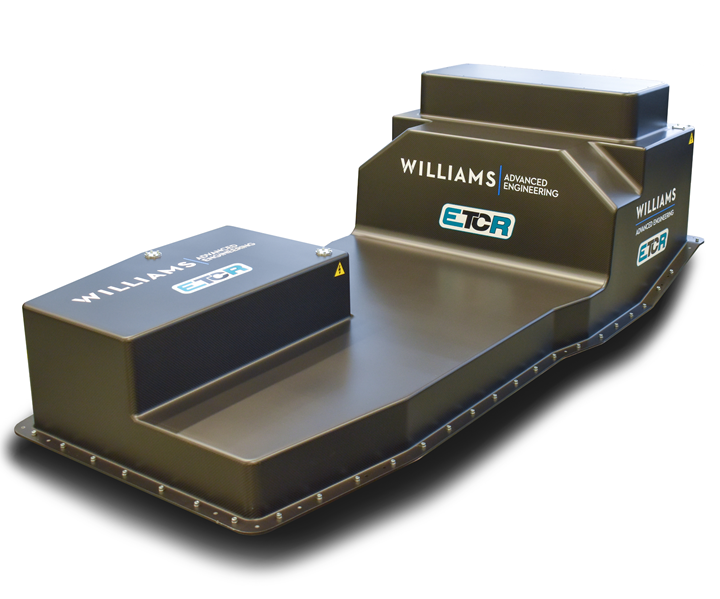

Williams Advanced Engineering completes battery pack for electric car racing

The battery packs, which feature composite enclosures, were completed in 7 months for the ETCR Touring Series.

Source | Williams Advanced Engineering

Williams Advanced Engineering (WAE, Grove, U.K.) reported on March 13 that it has designed and built a bespoke battery pack for ETCR, the planned Touring Car series for 100% electric vehicles. According to WAE, the project was completed in just seven months after the company was appointed sole battery pack supplier for ETCR in May 2019.

By June 2019, WAE reports that a cell and prototype module tests were already underway. Extensive Computational Fluid Dynamics (CFD) and finite element analysis (FEA) simulations were run in September 2019, allowing for manufacture in December followed by physical testing.

The 798-volt battery pack provides a peak power of 500 kilowatts and 300 kilowatts of continuous power, with a 62 kilowatt-hour capacity and the ability to be recharged in less than an hour from 10% to 90% at 60 kilowatt-hours. The pack will also allow four “push-to-pass” events over the 21-minute race distance, WAE says.

Source | Wiliams Advanced Engineering

Through FEA analysis, WAE’s composite enclosure for the battery pack has been designed to provide an electrical barrier against electro-magnetic current and to survive a 50g crash simulation. CFD thermal analysis was performed at both cell and pack level to model in detail the thermal characteristics of the battery pack in order to optimize cooling and weight efficiency. WAE reports that every battery goes through end of line trials to verify production build quality.

ETCR will be the first multi-brand Touring Car series with production cars powered by a common 100% electric powertrain. It plans to establish itself first across Europe, Asia and North America, racing on both street circuits and permanent tracks, and using connectivity and new technologies to deliver a new format with race data available to spectators at the event and online. The first event is scheduled in July 2020 at Goodwood Festival of Speed.

“We are delighted to be involved in this exciting program and to have delivered a fully operational battery in such a short time frame,” says Iain Wight, business development director at Williams Advanced Engineering. “We look forward to supporting the Series’ first event in the U.K. later this year.”

Related Content

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

.jpg;width=70;height=70;mode=crop)