AON3D introduces high-temperature 3D printer, software platform

The Hylo “smart” printer and accompanying Basis software simplify and expedite the printing of open market materials, fiber-reinforced composites and polymers.

Share

Read Next

AON3D (Montreal, Quebec, Canada), a North American manufacturer of industrial 3D printers and software, unveils Hylo, a new “smart” high-temperature 3D printer, and Basis, an additive manufacturing (AM) software equipped with process simulation, machine learning-driven thermal optimization and part qualification tools. Together, the two solutions simplify and expedite the process of printing open market materials, carbon fiber composites and high-performance polymers — materials with greater specific strength than many metals, continuous use temperatures up to 260°C, extreme chemical resistance and more.

Hylo is capable of using chopped carbon, glass and Kevlar fiber reinforcement. Notably, the company says, it also prints with carbon fiber-reinforced polyetheretherketone (PEEK), aided through Hylo and Basis’ leveraging of process simulation and automation to integrate material awareness into the slicing process.

With a 25.6" × 17.7" × 17.7" build area, a 250°C chamber and more than 8X throughput, Hylo maintains print speeds up to 500 mm/s and IDEX-enabled duplication/support modes. Beyond its specifications, the 3D printer featuring advanced process control and monitoring, accompanied by thermal optimization software. Equipped with more than 25 integrated sensors, Hylo manufactures reliable, accurate and strong parts in open market materials by continually monitoring, controlling and compensating for process variability.

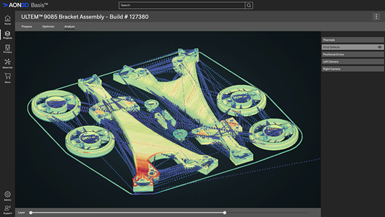

A digital twin of a 3D-printed part shows an area of a print that began warping. Including warping, AON3D’s Basis allows manufacturers to identify and prevent defects such as cracking, over/under extrusion, thermal variations, internal defects, dross/debris inclusions and more.

Basis is the foundation of AON3D’s new product ecosystem. Smart hardware is combined with intelligent slicing and in-process monitoring, turning process variability into part confidence with just a few clicks. While complete details are not yet released, AON3D Basis adds material-specific thermal awareness to the slicing process, dynamically tuning process parameters to optimize properties such as layer weld strength, dimensional accuracy, surface finish and more.

In addition, AON3D Basis users can quickly verify printed part quality by viewing Hylo’s process monitoring data in three dimensions. AON3D’s quality control tool also captures warping/cracking, over/under extrusion, filament diameter variances, hidden defects, dross/debris inclusion and other important features.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.