Base Materials launches BE368 epoxy tooling board

Medium-temperature material is designed for the manufacture of master models, patterns, jigs and fixtures.

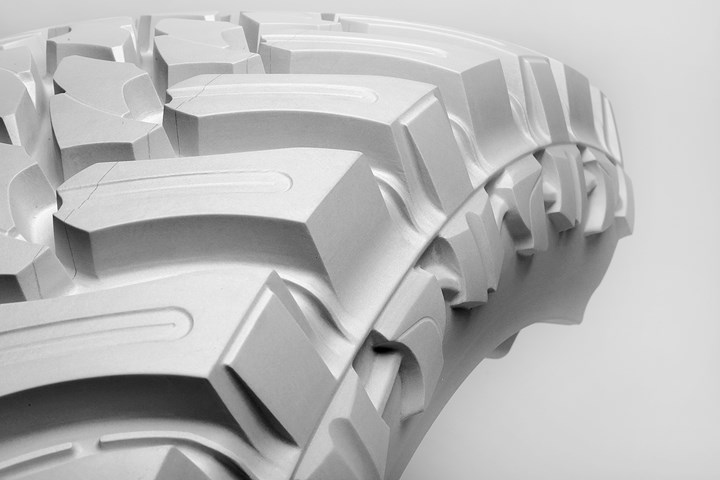

Base Materials (Leicester, U.K.) strengthens its epoxy materials range with the launch of BE368, a new medium-temperature, everyday tooling material designed for the manufacture of master models, patterns, jigs and fixtures.

Suitable for use across a range of industries including automotive, aerospace and motorsport, the BE368 epoxy tooling board features a good surface finish, a low coefficient of thermal expansion (CTE), improved dimensional stability and an inert surface for wide-ranging compatibility at temperatures up to +165ºC.

“Borne from our long-standing commitment to investing in research and development, the new BE368 is formulated to provide our customers with the option of a new cost-competitive material, for more everyday applications,” John Miller, managing director of Base Materials, says.

Base Materials’ BE368 epoxy tooling material, which is manufactured in-house, is available in a number of board thicknesses up to 150 mm. Base Materials also produces a full range of ancillary products, which includes adhesives, sealers and release agents.

Related Content

-

Plant tour: Airtech International, Springfield, Tenn., U.S.

Fifty years of supplying materials for composites manufacturing includes custom fabrication and now aims to advance 3D-printed tooling, parts and new resins.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

Mold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.