CAMX 2021 exhibit preview: A&P Technology

A&P Technology highlights its TX-45, which combines the mechanical performance of T1100G 71E 12k carbon fiber and offers significant cost savings.

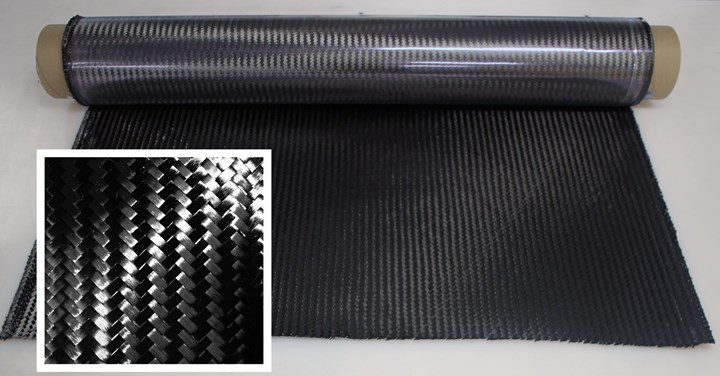

Photo Credit: A&P Technology

A&P Technology (Cincinnati, Ohio, U.S.) converts Toray Composite Materials America’s (TCMA, Tacoma, Wash., U.S.) T1100G 71E 12k carbon fiber into TX-45 — 197 GSM 45° fabric — which the company says provides performance improvements and significant cost savings.

T1100G 71E 12k carbon fiber offers a strength of 1,017 KSI and a tensile modulus of elasticity at 47 MSI. This combination of high strength and high modulus allows composite fabricators to reduce weight without sacrificing performance.

A&P Technology reports that its braiding equipment, capable of handling a range of fiber types, is able to process T1100G 71 E 12k into a lightweight, 45° fabric combining the advantages of T1100 performance with the cost savings found with off-the-roll 45° material. TX-45 is a continuous 45° fabric with uniform fiber architecture delivered on carrier film that enables easy handling and consistent fiber orientation. For parts requiring high shear strength, TX-45 reportedly eliminates the need to cut woven fabric on the bias to create 45° material, reducing labor and eliminating waste. In addition, TX-45 provides extreme drapability for highly contoured parts.

Further, A&P Technology notes that the optimized mechanical performance, cost and time savings enabled by T1100 IM+ TX-45, as well as A&P’s 0°, ±60° QISO fabric made with T1100, has attracted the attention of several aerospace customers interested in qualifying this material. TCMA and A&P Technology are pursuing development of a T1100G 71E TX-45 database to expedite qualification efforts.

Related Content

-

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

.jpg;maxWidth=300;quality=90)