Toray Composite Materials America, Inc.

19002 50th Ave East

Tacoma, WA 98446 US

253-846-1777

karen.lago@toraycma.com

toraycma.com

About Toray Composite Materials America, Inc.

Manufacturer of carbon fiber and thermoset prepreg materials: Services the aircraft primary structures market with 350°F highly toughened resin systems; 270°F-cure general-aviation AGATE products, with accompanying FAA-approved lamina and laminate databases and M&P specifications.

IS THIS YOUR COMPANY?

Video Gallery

From Fabric to Flight: How Toray Powers Epic’s Cutting-Edge Aircraft

Discover how Epic Aircraft has partnered with Toray for nearly two decades to create high-performance turboprop aircraft.

Elevating Griffon Aerospace with Toray's High-Performance Materials and Supply Chain Excellence

For Griffon Aerospace, Toray has been a reliable source of composite materials with publicly available databases. Toray's ...

The Toray Difference

At Toray, we're more than a materials provider - we're a reliable partner, committed to understanding our customers' unique ...

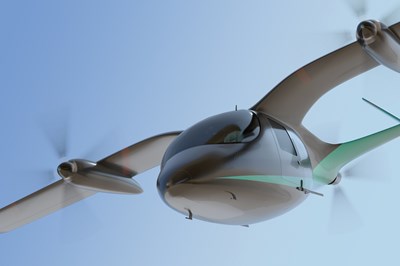

Toray's Role in Enabling Overair's Advanced eVTOL Propulsion System

A Partnership Beyond Materials: Dive into the collaborative journey between Toray and Overair. From engineering insights to ...

As Seen On CompositesWorld

Toray Composite Materials America, Inc. Supplies the Following Products

- Aerospace, fuselage/wing

- Aerospace, radomes

- Automotive, body panels & substructures

- Carbon, PAN-based

- Carbon, Yarns

- Epoxy, <12K tow

- Epoxy, >12K tow

- Epoxy, 250 F cure, <12K tow

- Epoxy, 250 F cure, >12K tow

- Epoxy, 250 F cure, 12-inch tape

- Epoxy, 250 F cure, 3-inch tape

- Epoxy, 250 F cure, 6-inch tape

- Epoxy, 250 F cure, 60-inch tape

- Epoxy, 250 F cure, Fabric

- Epoxy, 250 F cure, Other broadgoods

- Epoxy, 250 F cure, Other tape

- Epoxy, 3-inch tape

- Epoxy, 350 F cure, <12K tow

- Epoxy, 350 F cure, >12K tow

- Epoxy, 350 F cure, 12-inch tape

- Epoxy, 350 F cure, 3-inch tape

- Epoxy, 350 F cure, 6-inch tape

- Epoxy, 350 F cure, 60-inch tape

- Epoxy, 350 F cure, Fabric

- Epoxy, 350 F cure, Other broadgoods

- Epoxy, 350 F cure, Other tape

- Epoxy, 6-inch tape

- Epoxy, 60-inch tape

- Epoxy, Fabric

- Epoxy, Other broadgoods

- Epoxy, Other tape

- Epoxy, toughened, <12K tow

- Epoxy, toughened, 12-inch tape

- Epoxy, toughened, 3-inch tape

- Epoxy, toughened, 6-inch tape

- Epoxy, toughened, 60-inch tape

- Epoxy, toughened, Fabric

- Epoxy, toughened, Other broadgoods

- Epoxy, toughened, Other tape

- Testing, materials

Trade Names Offered by Toray Composite Materials America, Inc.

Editorial, News, and Products

-

Trends fueling the composites recycling movement

Various recycling methods are being considered for composites, from novel dismantling and processing, to building capacity and demonstrating secondary use applications.

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

-

Bell V-280 Valor gains clearance for EMD phase, prototype building

FLRAA aircraft featuring composite structures from GKN, Spirit and Unitech moves into design maturation and prototyping for anticipated 2026 flight schedule.

-

Toray carbon fiber line dedicated to U.S. Army FLRAA support

Decatur Torayca T1100 production line milestone instills confidence in development of lightweight airframes for Bell Textron V-280 air vehicle concept demonstrator.

-

Toray, Elevated Materials repurpose carbon fiber prepreg waste

MOU advances efforts to reduce waste, conserve resources and decrease pollution through upcycling of Toray’s composite material scrap.

-

Designing and manufacturing turbine test nacelles

Michigan-based Ground Test Solutions (GTS) shares the design and manufacturing processes involved in building composite nacelle components used in testing jet and helicopter engines.

-

Toray celebrates commissioning of expanded Torayca T1100 production line

Doubled carbon fiber production capacity at Toray’s Decatur, Alabama, plant will support rising demand in U.S. defense.

-

From the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

-

Upcoming CW Tech Days navigates composites in AAM

Don’t miss the Dec. 7th “CW Tech Days: Composites in advanced air mobility,” from 11 a.m. to 3:30 p.m., where materials suppliers and OEMS will discuss challenges and provide insight to better prep the composites industry for the AAM market’s demands.

-

Toray announces opening of AAM collaboration space in Ohio

As part of the National Advanced Air Mobility Center of Excellence (NAAMCE) space, Toray enables a closer partnership between AAM community members and global composite material experts.

-

Toray receives Boeing Supplier of the Year award

Tacoma-based Toray Composite Materials America was one out of 12 companies selected for its consistent and quality supply of carbon fiber and prepregs on various Boeing programs over the years.

-

Toray Advanced Composites to expand Morgan Hill operations

A 74,000-square-foot expansion will increase advanced composites production capacity by 50% in preparation for surging market demand.

-

Toray to increase carbon fiber tow capacity by more than 20%

Capital investments to Spartanburg, S.C., and Gumi, Korea facilities, in response to market demand, will increase annual capability to 35,000 metrics tons beginning in 2025.

-

Toray, Specialty Materials strengthen partnership for next-gen aerospace applications

Commercial partnership enables novel solution innovations with domestically produced, high-quality products within the U.S. supply chain.

-

Toray Composite Materials America to double Torayca T1100 production capacity

The upgrade to the company’s Decatur, Alabama, carbon fiber plant is set to begin April 2023 in order to support rising demand in defense applications.

-

Overair's Butterfly eVTOL prototype to integrate composites-intensive design

Aiming for first flight tests in the latter half of 2023, Overair’s Butterfly aircraft uses Toray carbon fiber/epoxy prepreg strategically to cut weight on its battery-powered, quiet aircraft.

-

Overair Butterfly eVTOL to incorporate Toray carbon fiber, resin system

The Butterfly is expected to take flight in densely populated cities in 2023, complete with Toray’s T1100/3960 prepreg system used in the airframe structure and propulsion units.

-

Toray supplies HiCAM project with thermoset, thermoplastic prepreg technologies

Toray Composite Materials America and Toray Advanced Composites divisions support technologies reducing cost, improving performance and increasing delivery rates in airframe manufacturing.

-

Toray and Bell collaborate on new NCAMP design allowable dataset for 3960 prepreg system

Allowable design dataset establishes conformity requirements and process specifications for traditional hand layup and AFP of the 3960 prepreg system in aerospace applications.

-

Multi-composite thrust chamber aims to boost rockets, reduce cost for New Space economy

Black Engine uses new, microporous CMC liner for transpiration cooling and multiple lightweight composites in modular design that offers increased lifetime and lower maintenance versus current launch vehicle engines.

-

Envisioning high-volume, 100% composite wheels

Vision Wheel debuted its first carbon fiber composite wheel at CAMX 2021, claiming its low-cost, high-volume process can be scaled up for performance vehicles, UTVs and — ultimately — passenger EVs.

-

The outlook for carbon fiber supply and demand

The picture painted at Carbon Fiber 2021 concerning the current supply and demand for carbon fiber indicates an in-flux, rapidly changing environment across a majority of end markets.

-

Designing for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

-

CAMX 2021 exhibit preview: A&P Technology

A&P Technology highlights its TX-45, which combines the mechanical performance of T1100G 71E 12k carbon fiber and offers significant cost savings.

-

Toray Composite Materials America launches flexible, adaptive 2700 prepreg system

Particularly geared toward emerging aerospace programs, the epoxy-based meets demands for high performance and process flexibility from prototype to high-volume production.

-

Toray announces new AMS specification for CMA 3900 prepreg system

New family of structural prepregs are now available with an extensive public allowable design database.

-

University of South Alabama, MHP engage in research partnership for plastic composite material

ZT-CFRP, enriched with specifically oriented nanoparticles and reinforced with carbon fibers, shows considerable potential when compared to conventional CFRPs.

-

Bye Aerospace eFlyer 2 assembly underway

All-electric aircraft nears FAA certification with composite fuselage and wing assembly, and a current backlog of 717 purchase deposit agreements.

-

Composites design helps nano-sized lunar rover hit big milestones

Developed by Carnegie Mellon University, the ultralight, composites-intensive Iris nano-rover will make its lunar debut later this year.

-

Flexible carbon fiber plates enable high-performance footwear

Carbitex’s flexible carbon fiber/thermoplastic composite plates use creative engineering to eliminate design compromises in athletic footwear.

-

TU Munich gears up for full-scale Hyperloop demonstrator

As a new, university-directed research program, the Technical University of Munich Hyperloop team works to scale up its SpaceX competition-winning pod design.

-

Developing a linerless, all-composite, spherical cryotank

Infinite Composites Technologies’ Type V pressure vessel for storing cryogenic space launch vehicle propellants shows promise for eliminating elusive microcracking issues.

-

Toray reduces carbon fiber and prepreg production

Toray will suspend operations in Spartanburg, S.C., U.S., and reduce prepreg capacity in Tacoma, Wash., U.S.

-

DH Sutherland, Toray Composite Materials America to support Boeing aftermarket aircraft

The global distribution partnership is designed to rapidly supply TCMA materials to commercial airlines and MRO customers.

-

Toray to provide prepreg carbon fiber for OceanGate submersibles

Materials from Toray Composite Materials America have been selected for composite pressure vessels on deep-sea submersibles.

-

Carbon fiber suppliers gear up for next-gen growth

CompositesWorld’s annual Carbon Fiber conference was held in Knoxville, Tenn., U.S., in late 2019 and included a pre-conference seminar focused on carbon fiber supply and demand.

-

IACMI: Driving innovation in the advanced composites industry

Since its start in 2015, the Institute for Advanced Composites Manufacturing Innovation (IACMI) has come a long way in its mission of advancing composites innovation. CTO Uday Vaidya reflects on the past five years.

-

Into the Hyperloop

The role of composites in the fifth mode of transport.

-

2019 Paris Air Show: Highlights

The 2019 Paris Air Show may have lacked the glamour of a new aircraft program announcement, but the composites industry represented is clearly gearing up for next-generation aerospace manufacturing.

-

Spirit AeroSystems debuts next-generation composite fuselage panel

The 18-by-12-foot (5.5-by-3.7-meter) demonstrator panel debuted at the Paris Air Show features integrated skin and stringers and offers substantial cost savings combined with strong performance attributes.

-

Spirit AeroSystems invests in qualification program with Toray prepreg

The world’s largest aerospace tier supplier seizes the opportunity to develop its own allowables for a carbon fiber prepreg, setting an important precedent.

-

Web Industries' Seattle facility to speed delivery to Boeing, Toray

The new production facility will produce precision-formatted composites for OEMs in the Pacific Northwest, including the Boeing 777X assembly plant.

-

More from JEC World 2019

CW continues to share composites industry news, product releases and more as the editors unpack findings from JEC 2019.

-

Low-profile, high-performance manufacturer

Advanced Composite Products & Technology Inc. provides innovative and cost-efficient composite solutions to some of the most difficult and demanding real world applications.

-

Plant tour: Spirit AeroSystems, Wichita, KS

Spirit AeroSystems was an established aerospace supplier when it earned that distinction, winning the contract for the Boeing 787’s Section 41. Now its sights are set on the next generation of aircraft.

-

Plant tour: Van Horn Aviation, Tempe, AZ

Van Horn Aviation seized a real opportunity in helicopter blades, with little composites acumen but big desire. The rest is history worth reading.

-

Toray acquires TenCate Advanced Composites

Toray, the world’s largest carbon fiber manufacturer, will pay €930 million for TenCate Advanced Composites to shore up its thermoplastic composites capabilities.

-

Improving composites processing with automated inspection

Automated, in-situ inspection bypasses the bottleneck of manual inspection.

-

CRTC and IACMI to develop advanced carbon recycling equipment

Thanks to a new contract with IACMI, the CRTC will pioneer ways to automate processing of carbon prepreg scrap. This technology breakthrough is essential so recycled carbon fiber can be processed in high volumes, says CRTC.

-

Composites recycling: Gaining traction

Recycling of carbon fiber, glass fiber and — at last — resins, is growing as new players enter the space.

-

Google shoots the moon

Google Lunar XPRIZE contenders turn to space- and launch-friendly composites.

-

Carbon composite driveshaft: Tailorable performance

This racing and aftermarket specialist designs and produces custom driveshafts for multiple markets.

-

Nanocomp Technologies Inc., Merrimack, NH, US

Its millimeter-length macro CNTs are finally realizing their commercial composites potential, with spacecraft applications leading the way.

-

Supply and demand: Advanced fibers

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs

-

Composites help Bell V-280 toward Future Vertical Lift

Bell’s design for future military helicopter uses hybrid metal-composite construction and Large Cell Carbon Core technology for unitized wing.

-

Plant tour: Spirit AeroSystems: Prestwick, Scotland, UK

Global aerostructures giant Spirit AeroSystems ventures into out-of-autoclave (OAA) composites manufacturing via vacuum infusion.

-

Toray extends Boeing carbon fiber contract, will build new carbon fiber plant

Toray will build in South Carolina a 2,000-ton-capacity plant that integrates precursor, carbon fiber and prepreg production for the Boeing 787 and 777X.

-

Automotive composites: Thermosets for the fast zone

Epoxies continue to be developed for faster cure to meet automotive production rates.

-

Why South Carolina? Why now?

CW guest columnist Tom Lemire (T.F. Lemire Consulting Inc., Irvine, CA, US), comments on the aerospace industry's current attraction to this particular spot on the US map and wonders if it's the beginning of a trend.

-

New aerocomposites niche: Helicopter transmission gears?

A NASA study shows that steel/composite hybrid gears save significant weight, and could mitigate vibration-related noise.

-

Supply and demand: Advanced fibers (2015)

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs.

-

Destroyer deckhouse roof meets U.S. Navy fire code with phenolic composite

An all-composite deckhouse superstructure, built by Huntington Ingalls Industries (Gulfport, Miss.) cuts topside weight and enables stealth capability by reducing the radar signature of the U.S. Navy’s new, nearly $4 billion (USD) Zumwalt-class destroyer.

-

Composites carry the Curiosity rover to a safe Mars landing

From launch to touchdown, composites performed in flight and stuck the landing!

-

Nondestructive inspection: Better, faster and cheaper

Faced with new time and cost pressures, NDI system suppliers are integrating inspection with manufacturing to reduce its share in part cost and cycle time.

-

Toray makes waves with Zoltek purchase

Toray was already the largest carbon fiber maker in the world, and with Zoltek it not only gets bigger, but expands into new markets.

-

Revisioning the Viper: Clamshell hood challenge

Autoclave-cured carbon-fiber prepreg hood/fender combo proves as technically formidable as it is visually stunning.

-

In-house prepregging: Cost/benefit calculus

Scaled-down systems are flexible enough for R&D and production, but can they earn their keep?

-

Lightning strike protection strategies for composite aircraft

Tried-and-true materials thrive, but new approaches and new forms designed to process faster are entering the marketplace.

-

JEC 2013 at first blush

CT Editor-in-chief Jeff Sloan risks some immediate reactions to his week in Paris at the JEC Europe 2013 composites trade show.

-

Space mission maximized via minimized survivability

CFRP design and manufacturing flexibility prove key in first spacecraft fuel tank designed to disintegrate upon reentry for improved mission efficiency and debris mitigation.

-

Composite-cored conductors: Holding the line

After a decade of incremental inroads, two different composite-cored electric power transmission products are connecting with those who specify for the grid.

-

Self-deployable, composite satellite boom

Researchers design and validate a boom made of ultrathin carbon-fiber/epoxy laminate, using a novel, highly accurate analysis method.

-

Portable wind turbine powers the warrior

DARPA-financed program puts wind energy to use for battery and system recharging.

-

Antiballistics: Better defense, less expense

Armor applications grow on the strength of new markets, new composite materials.

-

Drag racing champ wins with composite rear wing

A composite rear wing assembly built by Aerodine Composites Group (Indianapolis, Ind.) was critical to 2010 NHRA Full Throttle Drag Racing Series champion Larry Dixon’s effort at the wheel of the Al-Anabi Top Fuel dragster.

-

SAMPE 2010 Seattle Showcase

SAMPE’s first-ever foray into Boeing Country wrapped up with the M&P organization’s biggest draw this decade.

-

Very Light Jets Creating A Demand For Composites

"Baby" jets are causing an aviation buzz but will the market exist?

-

Carbon fiber reclamation: Going commercial

As the first commercial-scale carbon fiber recycling operations go online, research continues into both recycling alternatives and applications for recyclate.

-

New twist in cycling: A truss bikers can trust

An "open tube" alternative to the solid-tube bike frame.

-

CNTs ride a rising tide of nanotech optimism

Dr. Louis Pilato offers facts, figures and comment on the growing utility of carbon nanotechnologies in composites applications.

-

DDG-1000 Zumwalt: Stealth warship

U.S. Navy navigates radar transparency, cost and weight challenges with composite superstructure design.

-

Restoring a museum masterpiece with composites

Carbon fiber/vinyl ester reinforcement extends the structural life of architectural and art-world landmark.

-

Shared composite material property databases

For more than a decade, NASA, FAA, industry and academia have been working toward the goal of creating a centralized composite material property database similar to that for metals. Their efforts, while productive, have not come with the war-like strength that the standardization of metals did. The composites industry is guided by Composite Materials Handbook 17 or CMH-17 (formerly known as MIL-HDBK-17).

-

Composites stabilize space-based telescope

Composite Primary Mirror Backplane Support Structure to hold James Webb Space Telescope’s thermal stability within extremely tight 38-nm dimensional tolerance.

-

Structural health monitoring: Composites get smart

New initiatives are mainstreaming real-time monitoring systems into composites on aircraft, wind blades and other critical performance structures.

-

Spread tow key to new hockey stick design

Nike Bauer Hockey, a producer of ice hockey equipment since 1927, recently used carbon-fiber reinforcement in its redesigned goaltending stick for professional goaltenders in the National Hockey League (NHL). A goalie’s stick is larger that a normal hockey stick, with a larger blade and paddle, and has to be stro

-

Tooling Update: New dimensions in tooling

Nanoenhancements, out-of-autoclave strategies and low-pressure RTM headline efforts to increase mold quality and productivity and cut tool cost.

-

Carbon fiber buys its way onboard

First used in one-off yacht and powerboat designs, where cost is no obstacle in the search for a performance edge in local regattas or around-the-world races, carbon fiber has since carved a niche in categories that were once the exclusive reserve of glass-reinforced composites, metals or wood. In applications as

-

Carbon Fiber in the Wind

Is there a market for carbon composites in wind turbine blade construction? Yes, but the real question is, how big will it be?

-

Boeing 787 Update

Approaching rollout and first flight, the 787 relies on innovations in composite materials and processes to hit its targets

-

Megayacht Composite Masts Get Smart

Freestanding square rigging is fully instrumented for structural health monitoring while under sail.

-

Plane Enthusiasts Plan LSA-compliant Composite Aircraft

Aspiring owners build and - plan to market - their own tandem seat, twin-boom pusher.

-

Autoclave Quality Outside The Autoclave?

Pioneers of out-of-autoclave processing in aerospace applications answer a qualified but enthusiastic Yes!

-

Composites connect with the world of cabling

Composite cables prove they can handle high tension - on land, over water and under the sea.

-

Corvette converts floor panels, wheelhousings from glass to chopped carbon

Since 1953, General Motor's Chevrolet Corvette has been a trendsetter in glass-reinforced automotive composites and has served as the test bed for many GM innovations.

-

Corvette Z06 adds carbon fiber fenders

Molder meets GM's performance, weight-reduction goals and achieves 14,000-part production target with autoclave-cured prepreg.

-

An update on composite tanks for cryogens

More automation, improved materials bring composite fuel tanks for space applications closer to reality.

-

Designing for dimensional stability in space

The accuracy of orbiting instruments depends on skillfully designed and manufactured composite components.

-

Boeing sets pace for composite usage in large civil aircraft

Innovative use of international supplier base to revolutionize aircraft manufacture.

-

Composite fan blade containment case

Innovative use of carbon-fiber braid yields a ductile structure that resists blade impact.

-

At the top and still climbing

Trek Bicycles' OCLV manufacturing method shortens cycle times and optimizes compaction in molded carbon fiber-bike frame components.

-

2005 NAIA Show highlights

Detroit Auto Show emphasizes powerful and eco-friendly vehicles.

-

Carbon fiber raises consumer performance index

Carbon bridges gap between large-volume sporting goods and aerospace to satisfy discriminating tastes in consumer and professional markets.

-

Anisotropic wind blade design expected to reduce wind-energy costs

Deliberately unbalanced laminate produces smoother power input from adaptive wind blades

-

Roll-wrapped golf club shafts feature sophisticated prepreg layup

Roll-wrapped golf shafts are produced through advanced laminate software program.

-

Composite manufacturers thrive on products manufactured for the Automotive Aftermarket

Carbon and fiberglass accessories make up a big chunk of this multi-billion-dollar industry.

-

Resin transfer molding and preforms for jet engine stators

New 3-D woven preforms and nanofillers will improve part quality and reduce manufacturing costs.

-

SparrowHawk all-carbon composite sailplane

The first-ever all-carbon composite sailplane yields unprecedented maneuverability and top performance.

-

Post-show review of the 2004 U.S. SAMPE Symposium

Largest-ever Symposium serves up a large helping of news and new technologies from advanced composites suppliers.

-

GENOA modeling software closely predicts composite structuralfailure

Progressive failure analysis and material-level damage modeling enable life prediction of composite structures.

-

Corvette gets leaner with carbon fiber hood

Advances in materials and processing yield high-volume, low-mass hood for GM flagship.

-

Designing The Chanute Aerobatic Aircraft

Finite element modeling speeds development time and reduces uncertainty.

-

Carbon Composites for Sports Cars and Mass Market Cars

A confluence of market demand, new product development and competition among automakers fuels growth in use of carbon fiber composites.

-

Towpreg Proves Cost-competitive For Wound Pressure Vessels

Design group's new winding option streamlines new pressure vessel development.

-

Composite Drill Pipe An Available Option

Lincoln has been producing flexible composite drill pipe for short-radius, horizontal drilling since 1991. Its nominal 2.375 inch /60.3 mm (OD), 30 ft/9m long pipe shaft is filament wound with 12K carbon fiber combined with glass fibers in epoxy resin over an elastomeric liner. Standard API rotary shoulder too