Dura Composites data analysis tool offers comprehensive product specifications

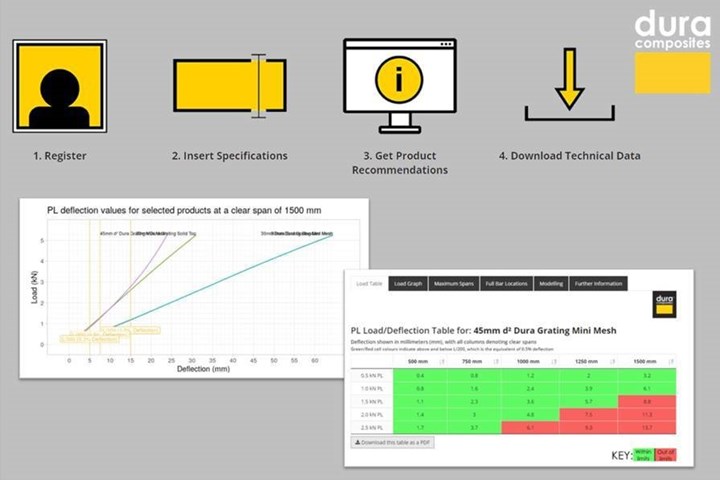

Interactive Product Selector identifies and details product information to streamline user selection and ensure fast and accurate product decisions for projects.

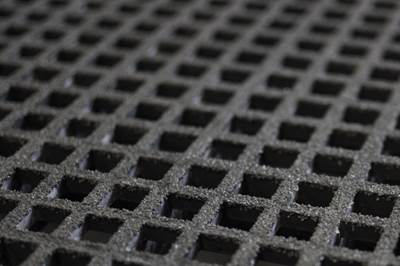

Photo Credit: Dura Composites

Dura Composites (Essex, U.K.) a global supplier of composite grating, walkways, access structures, profiles and risers, has recently launched a new online tool, the Interactive Product Selector, which the company says will help unlock the world of composite products for a vast range of architects, engineers, project managers and designers. With additional access to its new range of d2 Dura Grating series, the Interactive Product Selector is now available on Dura Composites’ website to help those within the industrial, construction, civil and facilities management industries to make fast and accurate decisions about the right product specification for their projects. Further, the tool is said to provide invaluable assistance at all stages of a user’s project lifecycle.

When considering walkway floor grating for example, users can choose their preferred product surface type (standard mesh, mini mesh or covered) and then input data relating to the project to narrow down product choice. The selections include the clear span dimension; the type of load (point load or uniformly distributed load); the maximum load requirement; the allowable deflection criteria (measured as a proportion of the span, i.e. L/200 or 0.5%); and the fire rating required. These filters are said to ensure that the resulting product selections meet the needs of the project specification.

Once a range of suitable products have been identified, detailed product information can be accessed immediately such as drawings, dimensions, load tables and graphs unique to these products. The selected span and load criteria can be downloaded into a neat professional document for analysis and approval.

Users can also compare products across the Dura Composites range with the click of a button the company says, with easy-to-interpret graphs collated into a single view. BIM data files which feature product information can also be downloaded from the tool, allowing architects and specifiers to streamline the design, build and maintenance process for time and cost savings.

According to Dura Composites, the Interactive Product Selector also streamlines a user’s selection of its d2 GRP Dura profile beam section, which bases it on whatever traditional beam may already be featured on a drawing. The specific steel or timber beam type and size can be selected from a drop-down list, the load criteria chosen alongside the span and the Selector Tool will generate which GRP Dura profiles meet or exceed the performance of steel or timber, as well as safety factor data.

Notable is the ability to compare GRP from other suppliers with Dura’s next-generation d2 materials, the company says. According to live test data, a d2 Dura profile has an average tensile modulus of more than 31GPa, which is said to far exceed the requirement of 23GP set out by the E23 European standard within BS EN 13706. This means that d2 Dura profiles are on average 88% stronger than other GRP profiles. The result, says Dura, is that a smaller, lighter and more cost-effective profile section can be used such as a 50 x 50 mm box section as opposed to a 64 x 64 mm size, saving 20% in weight.

To further help those who are new to the composites industry, Dura says its tool also features a Materials Properties section which allows users to delve into detail regarding each product range and a Property Comparison tool which enables visitors to compare how Dura Composites materials compare against more traditional materials used in construction, as well as against typical composite materials from other suppliers. These include specific strength, tensile strength, expansion, electrical resistivity and thermal conductivity.

The tool can be accessed at https://www.duracomposites.com/powerofcomposites/.

Read Next

Dura Composites appoints new United Arab Emirates GRP distributor

The partnership with UAE-based Sea Gulf Industrial Supplies will help Dura expand its global footprint and GRP products into the Middle Eastern industrial market.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More