Dynamic Modifiers introduces low-smoke, flame-retardant thermoplastic compound

Made for a wide range of markets, PAL...VersaCHAR addresses concerns surrounding traditional flame-retardant materials without sacrificing performance.

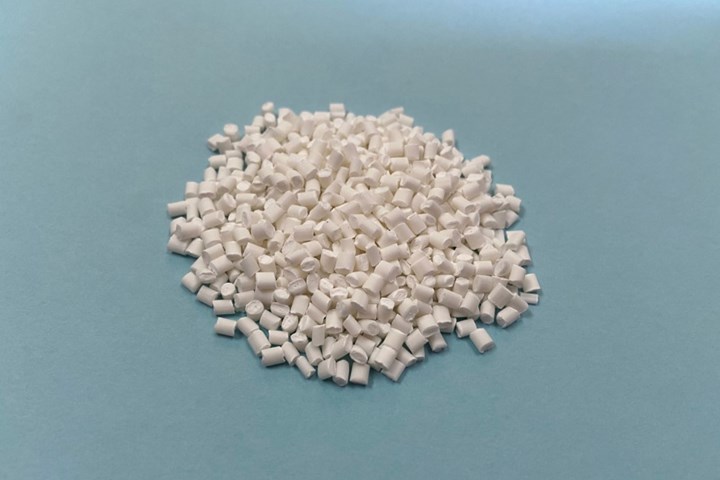

Photo Credit: Dynamic Modifiers

PAL...VersaCHAR, a non-halogenated, low-smoke, lightweight, flame-retardant thermoplastic polyolefin compound developed by Dynamic Modifiers LLC (Atlanta, Ga., U.S.), is said to address several concerns surrounding more traditional flame-retardant materials. Ideal for a wide range of markets — including aerospace, consumer, mass transit, marine, defense, oil and gas, construction and more — the technology is said to possess several advantageous and physical and performance qualities.

Compared to traditional thermoplastics, PAL...VersaCHAR is not bioaccumulative, meaning that it generates a very low smoke density. According to Dynamic Modifiers, the compound has passed ASTM E84 (Class A/1), which includes less than 2.3% of allowable smoke generation limits, and is able to match the stringent requirements of UL 94 V-0 flammability standard performances. Further, it does not contain or generate toxic off-gassing chemicals when exposed to flames, reducing the probability of high toxic combustion gas concentrations, which is a large concern for aerospace and public transport applications.

PAL...VersaCHAR is said to offer a low flame spread without flaming drips, and has been tested up to 1,950ºC (highest temperature tested to date). The material can be extruded or calendered as a film, sheet, coated fabric, molded to shape, or overmolded and bonded to most material substrates including metal for corrosion resistance. Properties of the compound include extreme chemical resistance and customizable UV, color, or glass fibers for added stiffness, toughness and tenacity.

PAL...VersaCHAR is fully recyclable, sustainable and also yields advantages to gain LEED points in the Green Building Market and Healthy Hospital Initiative. This can be seen through the compound’s ability to nominally modify hydrophobic or hydrophilic properties, as well as its high level of chemical, solvent and water resistance/absorbency. Further, the compound is non-polar, enabling a natural resistance to microbial growth. No volatile organic compounds, halogens or heavy metals are present.

Related Content

-

TenCate Advanced Armour renamed to Integris Composites

With its rebranding, Integris maintains the ability to develop, test and manufacture ballistic armor and survivability solutions while expanding into new markets where composite solutions can be advantageous.

-

Pull-wound carbon fiber poles enable lightweight, compact, rigid emergency stretcher

Based on military feedback, Epsilon Composite developed an optimized, foldable stretcher that combines telescopic pull-wound carbon fiber tubes.

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.