Electroimpact offers variable spot size laser AFP 4.0 technology

Patented process technology increases quality, reliability and machine utilization for composite laminate production.

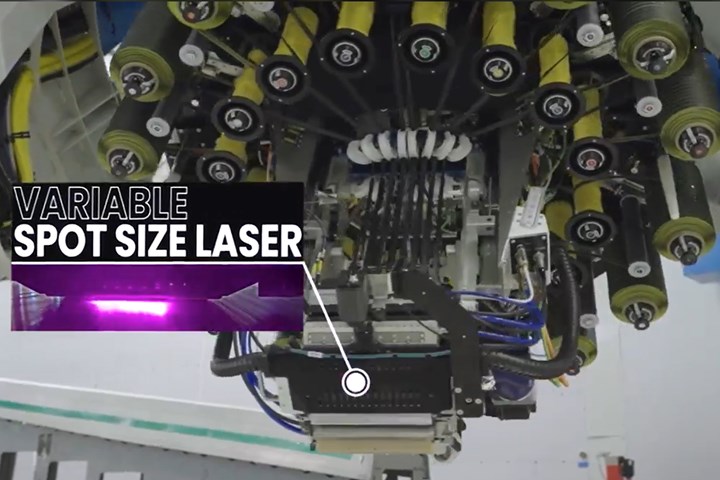

The variable spot size laser (VSSL) by Electroimpact’s (Multikeo, Wash., U.S.) automated fiber placement (AFP) group reportedly offers a new level of performance in automated composites manufacturing.

The VSSL is noted for its quality of lamination. The system delivers the right amount of heat for each individual tow, resulting in consistent tow tack even when adding at 4,000"/min. Tow end placement is highly accurate and consistent due to improved tension and tow tack.

Optimized tack means no missed tows, Electroimpact emphasizes, especially short tows, and thus a more reliable process. The servo-creel is a high-performance tension system that assures no slack and therefore no tow twists are possible. Because only the active tows are being heated and because the heat arrives at the moment the new tow meets the nip, there is no chance for a compaction roller wrap.

The VSSL laser and servo-creel enable 4,000"/min adds and 3,000"/min cuts, enhancing performance capabilities. Moreover, utilization has been increased, as the system is said to eliminate any rework or process error recovery.

For more information, see Electroimpact’s LinkedIn post.

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Rocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

.jpg;maxWidth=300;quality=90)