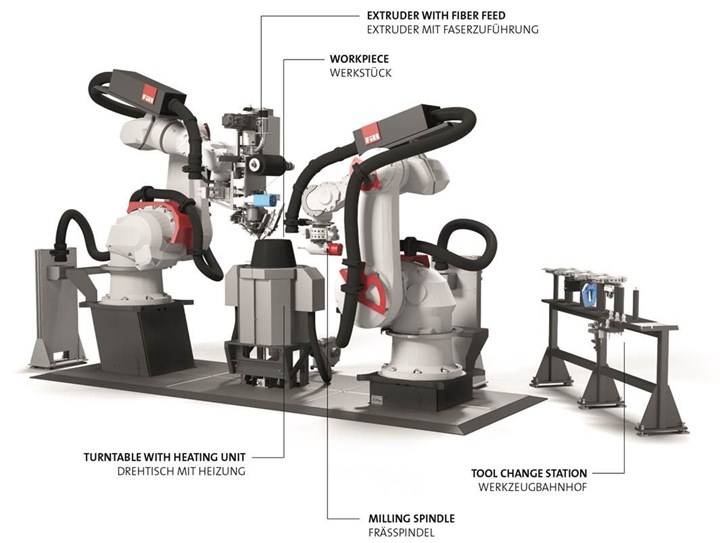

Fill ACCUBOT combines extrusion with continuous fiber additive capabilities

The system’s additive capability, augmented by subtraction via integrated robotic milling creates the potential for the production of cost-effective, high-performance and multifunctional composite components.

Photo Credit: Fill

The versatile properties of thermoplastics in combination with 3D printing processes offer almost endless possibilities for producing cost-effective, high-performance and multifunctional composite components. This is emphasized with composites and automation specialist Fill’s (Gurten, Austria) ACCUBOT (Accurate RoBot) technology, which provides not only the kinematics for such parts production, but also extruders and extrusion tools adapted to the requirements of 3D printing, thus providing additional degrees of freedom. These extrusions tools permit use of low-cost pellet materials, while ACCUBOT is also enabling continuous fiber to be fed into the melt.

The system’s additive capability is augmented by ‘subtraction’ via integrated robotic milling. Options such as automatic nozzle changing, filament feed with integrated cutting system, printed strand preheating, strand cooling and consolidation, as well as temperature monitoring in the printed strand, are said to permit new ways of thinking in the design and production of 3D-printed composites. If required, a second robot can be integrated for positioning inserts or for processing printed structures. A heated rotary table provides a construction platform with integrated temperature control of the assembly space. This ACCUBOT system is currently being installed at a German plastics institute.

According to Wilhelm Rupertsberger, head of Fill’s competence center for composites and polyurethanes, there is also potential to combine ACCUBOT with the company’s MULTILAYER additive manufacturing system for composite tapes. The first MULTILAYER system was remotely commissioned in 2020 at the Industry 4.0 Testlab for Composite Additive Manufacturing established by Swinburne University of Technology (SUT, Melbourne, Australia) and Australia’s Commonwealth Scientific and Industrial Research Organisation (CSIRO). Fill is now installing a second MULTILAYER at the Institute for Advanced Composite Manufacturing Innovation (IACMI) research facility in Detroit, Mich., U.S.

Related Content

-

TPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

-

Daher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

-

Bioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

.jpg;maxWidth=300;quality=90)