FILL Gesellschaft mbH

Competence Center Polyurethane and Composites

Fillstrasse 1

Gurten, 4942 AT

43 7757 7010 0

info@fill.co.at

fill.co.at/de

About FILL Gesellschaft mbH

Automated, machining, cutting, handilng and press technologies.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

FILL Gesellschaft mbH Supplies the Following Products

- Automated fiber placement

- Automated tape laying systems

- Braiding equipment

- Casting equipment

- CNC machining equipment (multiaxis)

- NDI equipment, ultrasonic

- NDI equipment, X-ray

- Preform manufacturing equipment

- Presses, compression molding

- Presses, hydraulic

- Presses, thermoforming/pressure forming

- Reaction injection molding equipment (RIM, RRIM, SRIM)

- Resin transfer molding equipment (RTM)

- Vacuum formers

- Vacuum-assisted resin transfer molding equipment (VARTM

- Welding and sealing

Editorial, News, and Products

-

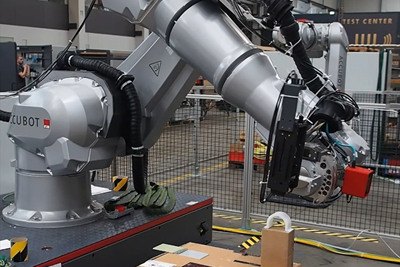

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

-

Innovation Award finalists revealed for JEC World 2024

Returning to the international composites trade show are the Innovation Awards, representing up to 33 finalists in 11 categories that highlight composites innovation excellence and fruitful collaborations.

-

JEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

-

Demonstrating functionalized, cost-effective composites using additive extrusion

Hybrid thermoset/thermoplastic composite part with 3D-printed functionalization demonstrates technology possibilities and EmpowerAX open platform offering expertise from members throughout the process chain.

-

Terahertz spectroscopy augments Fill Accubot NDT system

THz-Imaging spectrometry technique enables automated fiber-reinforced composite inspection for contorted and freeformed parts, and 3D-printed internal supporting structures.

-

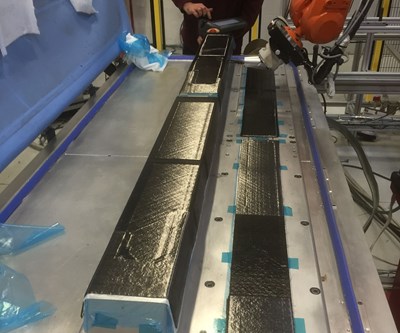

Multi-material steel/composite leaf spring targets lightweight, high-volume applications

Rassini International was challenged by Ford Motor Co. to take weight out of the F-150 pickup truck. Rassini responded with a multi-material steel/composite hybrid leaf spring system that can be manufactured at high volumes.

-

IACMI Members Meeting reconnects members, discusses road ahead

Oct. 5-7 in Detroit, Institute for Advanced Composites Manufacturing Innovation (IACMI) members presented automotive R&D and discussed industry trends.

-

Fill ACCUBOT spurs GKN Aerospace composite aircraft parts inspection

Flexible and precise multimodal robot system conducts quicker inspection processes, reducing GKN’s geometrical inspections from 11 hours to half an hour.

-

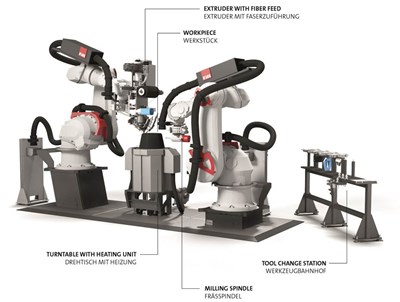

Fill ACCUBOT combines extrusion with continuous fiber additive capabilities

The system’s additive capability, augmented by subtraction via integrated robotic milling creates the potential for the production of cost-effective, high-performance and multifunctional composite components.

-

Hot drape forming

Heat, vacuum and/or pressure advance from debulking prepreg layups to automated preforming of dry reinforcements for faster composites production.

-

Fill completes new center for digitalization and software engineering

Future Zone in Austria explores future of production machines, system intelligence, and virtual and real symbiosis.

-

Composites 4.0: Architecture and ontology

Adaptive systems, IoT platforms and apps, the need for 4.0 standardization and a new way to develop and certify composite aerostructures.

-

Swinburne University and CSIRO's Industry 4.0 Testlab for Composite Additive Manufacturing

Australia and Germany collaborate to build Composites 4.0 production line for competitive advantage in next-gen manufacturing and workforce.

-

Engel, Fill develop automated cell for thermoplastic composites

The system combines a tape-laying cell with a consolidation unit to produce fit-for-purpose blanks with 15-30 tapes in 1-minute intervals.

-

Composites 4.0: digital assistants, edge computing and the future of smart factories

Plataine reviews developments and discusses where composites manufacturing is headed.

-

Automated joining of hybrid metal-thermoplastic composite structures

The FlexHyJoin production cell combines surface structuring, induction and laser joining and NDT for automotive mass production.

-

Plataine chosen for Swinburne-led project to advance Industry 4.0 manufacturing of industrial scale composites

At the SAMPE 2019 conference, the Australian Government’s Global Innovation Linkages Program announced funding for a joint project with Plataine, led by Swinburne University of Technology, to research techniques for manufacturing high volume, lightweight composites.

-

JEC World 2019 briefs

JEC briefs on Bindatex, FILL, Solvay, Henkel, Web Industries, Cobra, PolyOne, GKN Fokker, Thomas Technik + Innovation and Hyosung Advanced Materials.

-

Automated Preforming, Part 7: Fill Gesellschaft

Fill automates preforming for 1-min cycle time overmolded thermoplastic automotive parts but supplies automation throughout aero- and autocomposites process chains.

-

Rear wall reboot: One-stop, tow to tape to CFRP part

Audi and Voith Composites iterate the CFRP rear wall from R8 sports car to A8 luxury sedan via an automated production line able to output hundreds of parts per day.

-

Swinburne 4.0 test lab to feature Fill's multilayer printing technology

The centrepiece of Swinburne’s testlab is the world’s first industrial scale 3D printing “multilayer” approach to carbon fibre composite manufacture developed by Fill.

-

Fill to expand Austrian production facility

Preforming machinery specialist Fill GmbH will expand its production facility, adding 5,000m2 for machine and systems assembly.

-

Preforming goes industrial: Part 2

Automated preforming isn’t only for 2D and 2.5D parts. Innovators are taking successful aim at building 3D preforms at production speeds.

-

Preforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

-

Automated Preforming, Part 1: Numbers and Landscape

CW’s multi-blog series on preforming begins with an overview and quick look at the numbers: 1-minute take time, 10-15 seconds per layer, 490-kg/hr and 3.5 million parts/year. Are you ready for serial CFRP production?

-

JEC 2017 – Aiming for Industrialization

The exhibit floor in Paris reflected composites’ move toward high-rate and high-volume production.

-

Turnkey manufacturing systems: Materials, markets and maturation

Automated production cells promise affordability and less risk in scaling up composites production, but are they really the path forward?

-

BMW Leipzig: The epicenter of i3 production

A glimpse into the inner workings of an automaker at the forefront of serial-production autocomposites.