Hexagon, Authentise end-to-end software platform streamlines AM workflow

Solution integrates shop floor data with data intelligence to orchestrate consistent quality through concept to part for AM industrialization.

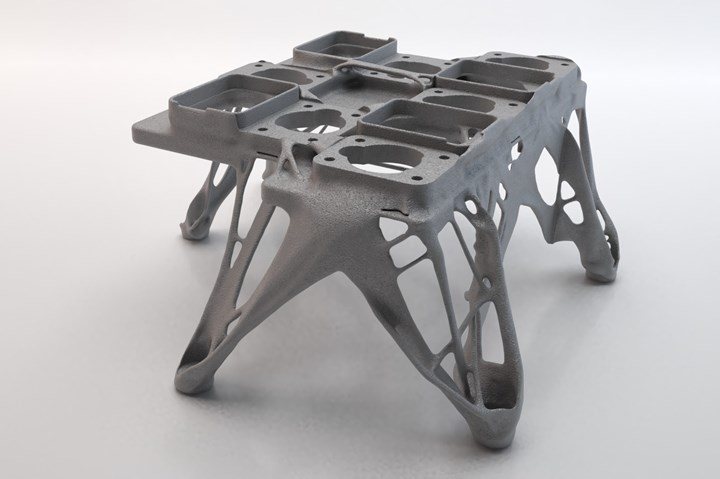

Optimizing this microwave filter using AM reduced its weight by 55%, while increasing stiffness by 79%. Photo Credit: Hexagon/Tesat-Spacecom GmbH & Co. KG.

Hexagon’s Manufacturing Intelligence division (North Kingstown, R.I., U.S.) and Authentise (Philadelphia, Pa., U.S.), a Manufacturing Execution System (MES) provider specializing in additive manufacturing (AM), have partnered to deliver a solution that connects the end-to-end 3D printing value chain from design, manufacturing operations and quality assurance to make AM more predictable, repeatable and traceable. Further, according to the company, as an AM workflow solution, it will generally cover all materials and processes, which has the potential to include composites.

New solutions delivered through this partnership will apply statistical process control (SPC) with machine learning (ML) and artificial intelligence (AI) methods to mitigate waste and quality issues during the design phase and improve the repeatability of AM processes within a site or between global locations.

This will be achieved by digitizing every step of the workflow, from part design, through production to the final product. Further, quality assurance will be offered, and will apply both company’s technology capabilities to connect the digital thread of a part and trace its pedigree. All of this is made possible by a shared commitment to open architectures that integrate data and automate workflows between Hexagon’s best-of-breed applications for AM and the third-party equipment and software manufacturers that are chosen. Ultimately, this solution will reportedly industrialize AM technology.

According to Mathieu Pérennou, global business development director of additive manufacturing, Hexagon’s Manufacturing Intelligence division, AM is a complex and changing market with many tools, printers and materials that can be applied. Hexagon believes its open and flexible systems will enable the company to respond quickly to customers’ needs and integrate with their unique environments. This will reportedly connect the data flow and help streamline end users’ workflows in all stages of the AM process, before, during and after production, and support their specific standards or compliance needs

Authentise’ CEO Andre Wegner, CEO, Authentise notes that ntegrating data from Hexagon’s best-of-breed software and sensors into Authentise’ workflow management engine will help deliver a seamless experience for users, automation across their process and unlocks the ability to learn from data.

Related Content

-

Siemens Gamesa, Airborne develop automatic preforming robot system for offshore wind blades

Danish-funded ALMA project furthers collaboration, adds new functionality, advanced sensor systems and digital twinning for reduced man-hours, waste and cost per blade.

-

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

-

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

.jpg;maxWidth=300;quality=90)