Hexagon unveils new PV Elite release for design, analysis of pressure vessels, heat exchangers

Complete software solution incorporates the tools necessary to perform a broad range of vessel analysis and boundary-defining data inputs, enabling efficient design while ensuring those designs are up to safety codes.

Share

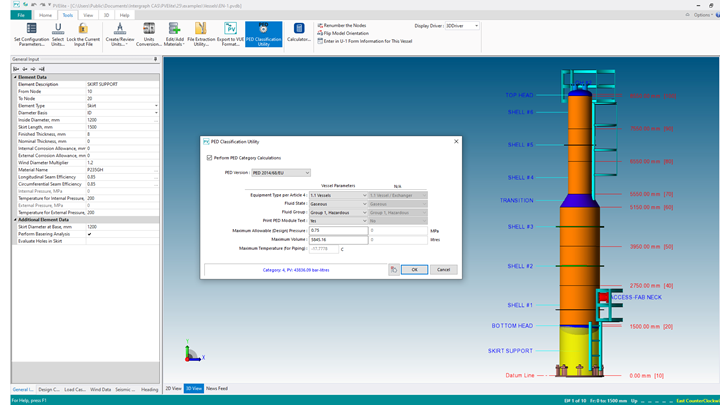

Hexagon’s (Huntsville, Ala., U.S.) Asset Lifecycle Intelligence division, a digital reality solutions provider, has announced the availability of a new version of PV Elite, its complete software solution for vessel and heat exchanger design, analysis and evaluation.

Since its launch three decades ago, Hexagon says PV Elite has helped users confidently design equipment for the most extreme uses. The new version provides them with expanded capabilities for additional safety.

Specifically, this latest release is said to incorporate all of the tools necessary to perform a broad range of vessel analysis and boundary-defining data inputs, enabling engineers to efficiently design and quickly comprehend results that ensure safety.

It includes:

- EN 13445 code enhancements, such as simplified fatigue analysis, creep design and blast loads for horizontal vessels.

- Rectangular vessel analysis for all supported codes.

- North American wind and seismic code updates.

- Material Database user experience enhancements.

This version of PV Elite also includes user experience enhancements, making it easy to learn, start up and use for new and experienced engineers alike. According to Hexagon, it streamlines data entry by breaking input into sensible subsets, while analysis may be done in one pass over the entire pressure vessel model or on individual components (such as shells, nozzles, flanges, etc.).

“Pressure vessel engineers are tasked with projects that vary greatly by size, type and material,” says Kristin Coyle, product owner, Hexagon’s Asset Lifecycle Intelligence division. “This new version of PV Elite provides them with everything they need to improve their productivity, save time and optimize engineering design using enhanced data capabilities. In addition, it’s easier than ever to learn and use, which makes it perfect for users requiring fast start-up and confidence in their safety code calculations.”

According to Maximilian Stechhammer, head of sales and marketing, Hering AG, PV Elite has helped his company reduce engineering and calculation costs by 30% while maintaining high quality.

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

ATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

-

Optimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

.jpg;maxWidth=300;quality=90)