KraussMaffei launches large-scale 3D printer, print-on-demand services

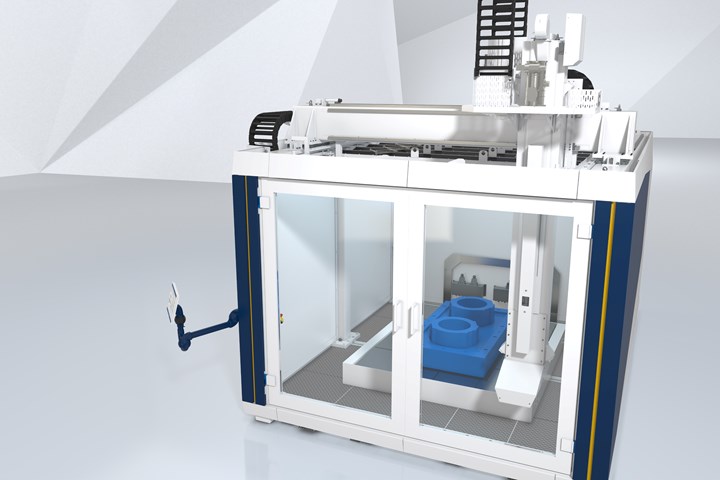

PowerPrint, capable of using fiber-reinforced compounds, combines design freedom and cost efficiency for large-format printing applications. It is available for purchase or serviced through KraussMaffei.

KraussMaffei’s (Parsdorf, Germany) large-scale 3D printer, powerPrint, which is capable of printing components up to 2 × 2.5 × 2 in size, is now available for purchase. Alternately, KraussMaffei offers a print-on-demand service.

The powerPrint large-scale printer is said to open up new fields of application for additive manufacturing. Since its introduction in 2022, it has been successfully tested to use a variety of fiber-reinforced composite compounds. KraussMaffei noted to CW that these compounds could also include other fibers apart from chopped fiber depending on the fiber length required. According to Rolf Mack, vice president of additive manufacturing, “the powerPrint is ready to produce custom parts for the customer at the customer’s facility with the highest industry and quality standards.”

Its basis for cost-effective production of 3D objects is the use of thermoplastics in granulate form and extruder-based pressure buildup (nozzle area 2 to 20 mm). The powerPrint offers a high output rate (up to 30 kg/h) with high product quality, KraussMaffei reports. It is capable of producing components independently and without manual intervention at a temperature of up to 350°C. Parts are removed from the machine from the front through a door or by crane via a folding roof in the heat-resistant enclosure. Print jobs can be changed quickly thanks to vacuum-fixed printing plates. A specially developed HMI ensures intuitive and simple operation of the device, while ensuring a high level of work safety.

PowerPrint is suitable for all industries that require large-format objects with consistently high product quality, such as tool and moldmakers, packaging and logistics and the automotive industry.

KraussMaffei also offers a print-on-demand service as an alternative to purchase. In this service, applications are designed according to customer specifications and technical possibilities and then printed, with KraussMaffei also handling post-processing. The powerPrint has already implemented several components in this way, such as a molding tool for the vacuum infusion process, a sand casting mold and a charging column, among others.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

.jpg;maxWidth=300;quality=90)