Time Bicycles to modernize composite bicycle manufacturing

With the aid of KraussMaffei, Clemson University and SC Fraunhofer USA Alliance, Time anticipates a transition to HP-RTM for more efficient carbon fiber bike frame manufacture, plus a new facility in South Carolina.

Share

Read Next

Time’s top-selling finish shows the aesthetic of the nude carbon fiber structure. Photo Credit: Time Bicycles

Time Bicycles (Gajary, Slovakia and Landrum, S.C., U.S.), a carbon fiber bicycle manufacturer, has been raced to victory in the Olympics, many stages of the Tour de France and multiple world championships. Time bicycle frames are made of multilayer braided carbon fiber sleeves and are handcrafted using resin transfer molding (RTM). The company is working closely with KraussMaffei (Parsdorf, Germany) to technically optimize its manufacturing process. To achieve this, a carbon fiber bicycle factory in the U.S. is being built in Spartanburg, South Carolina, reported to be the largest in the U.S.

The $6.5 million investment includes a 120,000-square-meter site with an existing factory (13,000 square meters in area). This is being upgraded to expand the capacity of Time’s location in Slovakia starting in winter 2023. For Time, bicycle production in the U.S. has been the plan for the past couple of years.

To further increase efficiency, the company is also cooperating with experts from Clemson University (S.C., U.S.) and the SC Fraunhofer USA Alliance (SCFUSA), which is a collaboration between the South Carolina Department of Commerce and Fraunhofer USA (Plymouth, Mich., U.S.). At Clemson, the new manufacturing process is being developed on an existing KraussMaffei system. The goal is to transform Time’s proven, albeit manual RTM technology into a high-pressure RTM (HP-RTM) process with a high degree of automation.

“Time was the pioneer of carbon [fiber] in professional bicycles,” Tony Karlins, Time CEO, contends. “Now we look forward to producing the most advanced carbon [fiber] frames in the entire industry.”

The main intention is to produce high-end racing bikes as well as e-bikes, which are also becoming increasingly popular in the U.S. According to David Judge, business development manager, KraussMaffei, “We are combining efficiency and price appeal with a product that historically has been handmade. For us, it is a wonderful endeavor to industrialize and automate this process without compromising Time’s commitment to quality.” The schedule aims to have clarity on the technology details by the middle of the year and then move on to the actual system design.

KraussMaffei is reported to be the only company in the plastics industry to manufacture machines for all processing methods in-house (reaction process machinery, injection molding, extrusion) — which may also be of interest for other components of Time bikes.

“We expect to be involved in all optimization processes,” Judge says. In addition to classic RTM, KraussMaffei can leverage its surface expertise, such as the ColorForm process and its self-healing polyurethane surfaces, to help ensure that frames come out of the machine ready to go and do not need to be laboriously reworked. Overall, this collaboration is expected to take bicycle manufacturing at Time to a new level of production.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

JEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

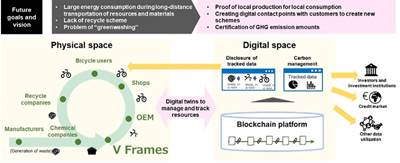

Read MoreFujitsu, Teijin start joint trials to promote value of recycled carbon fiber

Three-month trials with German bicycle manufacturers will lead to new platform implementation to promote use of recycled materials, enable emissions tracing/management.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More