KraussMaffei Technologies GmbH

KraussMaffei Group

Krauss-Maffei-Strasse 2

München, 80997 DE

49 89 88 99 0

info@kraussmaffei.com

kraussmaffei.com

About KraussMaffei Technologies GmbH

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

KraussMaffei Technologies GmbH Supplies the Following Products

- Extruders

- Foam application equipment

- Material handling equipment

- Metering/dispensing equipment

- Mixers

- Presses, injection Molding

- Prototype

- Reaction injection molding equipment (RIM, RRIM, SRIM)

- Resin injection

- Resin transfer molding equipment (RTM)

- Trimming equipment

Editorial, News, and Products

-

Pultruded CFRP chassis enables 36% payload increase for specialized commercial vehicles

CarbonTT’s quadraxial NCF composite chassis adds 185-kilogram capacity to Borco Höhns’ 3.5-ton Fiat Ducato market vehicle.

-

Biomaterials make strides toward composites sustainability

A compilation of trends in development or application of natural fibers, bio-based resins and more showcases industry players, educational institutes and global projects.

-

Composite Kape skateboard delivers durability, pop

Collaborative effort between KraussMaffei and entrepreneur Peter Karacsonyi led to the Vanguard, an in-situ polymerized board comprising fiberglass sandwich composites with a recyclable polyamide.

-

KraussMaffei, AIM collaboration achieves HP-RTM carbon fiber wheel rims

KraussMaffei supported, coordinated and delivered compact production equipment tailored to design and process needs for high-quality automotive rims.

-

NIAR, KraussMaffei cooperation enables efficient aerospace aircraft conversion

Incorporation of FiberForm advances NIAR ability to convert metallic components to fiber-reinforced thermoplastic versions in cargo aircraft.

-

Fiber Dynamics invests in GX 1100 DCIM from KraussMaffei

Direct compounding injection molding (DCIM) enables the composites company to develop, test and protect its own recipe formulations, while increasing cycle times by eight times and reducing energy consumption.

-

Comprehensive composites services cover concept to completion

JEC World 2024: KraussMaffei presents its complete technology portfolio in the fields of lightweight construction and surfaces, covering a variety of end markets.

-

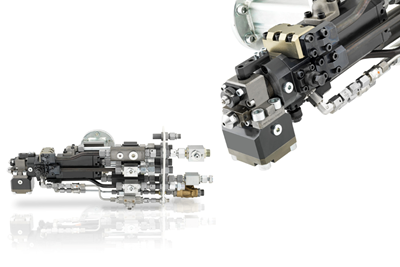

KraussMaffei optimizes SCS process with quick nozzle change module

Efficiency, resource optimization and environmental responsibility are key focuses behind the seamless switch between flat and round jet nozzles, used for spraying polyurethane onto composite components.

-

JEC Forum DACH reveals Startup Booster, AVK Innovation award winners

Awards highlight dynamic composite innovations in industry.

-

KraussMaffei completes largest relocation project to Parsdorf

One of four relocation projects since 2018, the modernized site will enable the 185-year-old company to operate efficiently, digitally and sustainably.

-

KraussMaffei introduces calculation tool to predict product lifecycle costs

The lifecycleValueCalculator is an example of how digitalization is supporting decarbonization for injection molding, extrusion and reaction process technologies by creating transparency about CO2 emissions.

-

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

-

KraussMaffei and partners develop sustainable, safe and stylish children’s bike

The Lion Bike is a German-made, injection molded bicycle with 40% recycled carbon fibers with zero scrap and enabling 67% lower CO2 emissions during production.

-

KraussMaffei launches large-scale 3D printer, print-on-demand services

PowerPrint, capable of using fiber-reinforced compounds, combines design freedom and cost efficiency for large-format printing applications. It is available for purchase or serviced through KraussMaffei.

-

Optimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

-

Time Bicycles to modernize composite bicycle manufacturing

With the aid of KraussMaffei, Clemson University and SC Fraunhofer USA Alliance, Time anticipates a transition to HP-RTM for more efficient carbon fiber bike frame manufacture, plus a new facility in South Carolina.

-

People in Composites: January 2023

Beyond Gravity, Wisconsin Oven, Exel Composites, Corebon, Strongwell, Hexcel, Norco Composites and many others in the industry have announced updates to company personnel.

-

Composites end markets: Aerospace (2023)

With COVID in the past and passengers flying again, commercial aircraft production is ramping up. The aerocomposites supply chain is busy developing new M&P for an approaching next-generation aircraft program.

-

KraussMaffei to relocate corporate headquarters to Parsdorf, Germany

The move from Munich and accompanying plant relocations represents the culmination of the 185-year-old group’s modernization strategy.

-

People in Composites: November 2022

New hires, appointments and changes in executive leadership have been announced by Wickert, Michelman, Altair, Fortify, KraussMaffei and the Aerospace Industries Association (AIA).

-

KraussMaffei adds additive manufacturing, sustainability to strategic focus

Presenting at this year’s K Show, the plastics company adds AM machines to its exisiting portfolio, positions itself to pursue a circular economy.

-

People in Composites: July 2022

New personnel announcements have been made in July by composites companies AGY Holding Corp., Airbus, STRUCTeam, Arris Composites and KraussMaffei.

-

People in Composites: June 2022

New personnel developments have been announced for companies like Lilium, Hexagon Digital Wave, Velocity Composites, KraussMaffei, Plastic Omnium and more.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

SAMPE North America to host Materials Innovation & Advanced Technology Leadership Forum

The Jan. 26-27, 2022, conference held in Huntington Beach, Calif., convenes composites stakeholders from a variety of end markets to address the industrialization of composites manufacturing.

-

People in Composites: October 2021

KraussMaffei, Composites United, Montalvo, Carbitex, Arkema Group, Vertical Aerospace and Lockheed Martin announce new appointment hires in the composites industry this month.

-

iPul pultrusion system enhances Carbon TT’s CFRP profile production for vehicle chassis

Krauss Maffei’s subsidiary, Pultrex, delivers a customized iPul pultrusion system for the production of large profile parts for around 70,000 vehicle chassis annually.

-

People in Composites: September 2021

KraussMaffei, CDI Energy Products and Massivit 3D announce new appointment hires in the composites industry this month.

-

CosiMo: Smart thermoplastic RTM process demonstrated for battery box cover challenge simulator

Project uses network of DEA, temperature/pressure and ultrasonic sensors plus digital simulation and AI modeling to monitor and optimize injection of caprolactam into complex glass fiber preform and in-situ polymerization of PA6.

-

People in Composites: May 2021

Illium Composites, Boom Supersonic, Hexion, AOC, KraussMaffei, Composites Integration and SPE announce new hires within the composites manufacturing industry.

-

People in Composites: January 2021

CW’s January people roundup covers new hires and appointees for Safran, Carbitex, Lilium, Boom Supersonic and KraussMaffei Group.

-

KraussMaffei recompounding line available for customer trials

Applicable for extrusion and injection molding, the line enables all post-consumer LDPE, HDPE, PP or PS fractions to be processed into recompounds.

-

People in Composites: March 2020

ACMA, KraussMaffei, FACC, LANXESS, and UAMMI announce new hires in the composites industry.

-

Chomarat glass fiber reinforcement lightens mass-produced auto parts

G-PLY, developed for KraussMaffei’s HP-RTM process, reportedly delivers weight savings of 60% for leaf springs.

-

PUR metering systems designed for digital integration

KraussMaffei’s EcoStar, RimStar and RimStar Smart mixing and metering machines support digitization in polyurethane (PUR) foam production.

-

KraussMaffei technology enables addition of expandable graphite to PUR foam

KraussMaffei’s technology for expandable graphite metering makes the material’s use as a flame retardant an alternative or addition to liquid admixtures.

-

HP-RTM for serial production of cost-effective CFRP aerostructures

Merging automotive process and tooling with aerospace quality to meet increasing production rates.

-

KraussMaffei expands LFI and SCS processing with shuttle mold carrier

At the Munich-based TechCenter, the MX mold carrier is developed to improve fiber injection and spraying capabilities including for large, Class-A components.

-

Thermoplastic overmolded thermosets, 2-minute cycle, one cell

Adhesive-free, functionalized hybrid composites enabled by industry-first, integrated molding cell.

-

Pultrusion picks up speed in automotive applications

Pultrusion is one of the most cost-effective processes for manufacturing high-volume composite parts.

-

AMRC installing UK's largest radial braider

The new radial triaxial braider will support the development of complex lightweight preforms for automotive, aerospace and other weight sensitive industries.

-

People on the Move: July 2018

CW’s monthly roundup of people on the move in the composites industry.

-

KraussMaffei invests in second-hand machinery start-up

The KraussMaffei Group is expanding its portfolio and digital offering with a stake in the German second-hand machinery start-up GINDUMAC GmbH.

-

KraussMaffei automated wetmolding system reduces cycle times

The new system is said to reduce the cycle time and increase process reliability compared with manual solutions.

-

New high-performance pipes for oil and gas industry from KraussMaffei

KraussMaffei has announced two pipe extrusion technologies including a new thermoplastic composite pipes pilot line and a three-layer pipe with a functional inner layer made of polyamide.

-

AMRC's high-pressure RTM and composite press facility open for R&D collaboration

The University of Sheffield’s Advanced Manufacturing Research Centre says its high-pressure RTM and composite press facility is now ready to host collaborative R&D projects with composites industry manufacturers.

-

JEC World 2018 preview: KraussMaffei

KraussMaffei (Hall 6, F61) is featuring several composites manufacturing technologies, covering wet molding, pultrusion, long fiber injection and overmolding.

-

Large, Class A parts every 60-150 seconds

Romeo RIM advances long fiber injection process efficiency for lighter, lower-cost composite parts.

-

Fraunhofer ICT in-mold pressure sensors for HP-RTM

Pressure sensor-based mold fill expected to maximize part consistency and minimize cycle time for auto industry molders.

-

A look inside Fraunhofer ICT

Fraunhofer-Gesellschaft (Munich, Germany) is the largest applied research organization in Europe, with more than 67 institutes and research units located throughout Germany staffed by 24,500 people, mostly scientists and engineers. CW recently got a chance to tour one, Fraunhofer ICT in Pfintzal, Germany.

-

Automated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

-

Curved pultrusion? No longer an oxymoron

Radius-Pultrusion process offers linear or curved profiles.

-

JEC World 2017: Show report, part 1

JEC World 2017 was, by almost any measure, the biggest and busiest JEC event yet, and exhibitors came with much to show the world of composites about innovation in materials, equipment and technology.

-

500,000 parts per year? No problem!

BENTELER-SGL develops fully automated HP-RTM production of the weight- and space-saving composite leaf spring for Volvo’s multi-model SPA global platform.

-

KraussMaffei's new one-step forming and back injection for composites

KraussMaffei is working on the development of new hybrid materials and processes in collaboration with the Dresden University of Technology.

-

CW Plant Tour: Composite Technology Center, Stade, Germany

A cornerstone of Germany’s CFK Valley, CTC pushes composites forward via automation, recycling, digital thread-based manufacturing and more.

-

Video: KraussMaffei T-RTM demo at K 2016

Live demos are found almost everywhere you look during the K show. One of particular interest was KraussMaffei’s Thermoplastic Resin Transfer Molding (T-RTM) demo.

-

BMW 7 Series Plant: Dingolfing, Germany

Via four different manufacturing methods, CFRP goes mainstream in automated multi-material BIW and assembly operations at BMW’s busiest plant.

-

Getting real: Thermoplastic resin transfer molding

KraussMaffei is launching this fall thermoplastic resin transfer molding (T-RTM), through which caprolactam is injected into a preform and then in-mold polymerized to create polyamide 6.

-

LG Hausys invests in HP-RTM machine from KraussMaffei

The machine is producing advanced structural components for the visible part of automobiles, including a CFRP roof panel.

-

Turnkey manufacturing systems: Simplifying automated HP-RTM

Having offered turnkey systems for composites since the 1990s for sheet molding compound (SMC), long fiber thermoplastic (LFT) and glass mat thermoplastic (GMT), Dieffenbacher (Eppingen, Germany) now has automated systems for high-pressure resin transfer molding (HP-RTM).

-

Turnkey manufacturing systems: Materials, markets and maturation

Automated production cells promise affordability and less risk in scaling up composites production, but are they really the path forward?

-

Automotive composites: Thermosets for the fast zone

Epoxies continue to be developed for faster cure to meet automotive production rates.

-

The rise of HP-RTM

Decades of development have propelled it to prominence but its future demands industrial solutions for handling cost, complexity and process control.

-

Thermoplastic composites feel the love at NPE2015

At NPE2015, some of the key players involved in thermoplastic composites exhibited a variety of solutions that are leading growth in new and emerging markets.

-

SPE ACCE report

Automotive composites still on the horizon — are they getting closer?

-

CAMISMA’s car seat back: Hybrid composite for high volume

Recycled fibers, in-situ polymerized PA12 and steel inserts combined in one-shot process to cut weight 40 percent at competitive cost, cycle time and safety.

-

SPE ACCE 2014 report

Automotive composites still on the horizon — are they getting closer?

-

2014 JEC Europe Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

BMW Leipzig: The epicenter of i3 production

A glimpse into the inner workings of an automaker at the forefront of serial-production autocomposites.

-

JEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

Business and busy-ness

CT editor-in-chief Jeff Sloan returns for JEC Europe 2014 in Paris with observations about several intriguing composites industry trends.

-

JEC Europe 2013 new product showcase

The JEC Europe 2013 trade show (March 12-14, at the Paris Expo, Porte de Versailles, Paris, France) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the CT editorial staff's compilation of what was on display.

-

LFI process: Molding strong and attractive spa enclosures

Dynasty Spas (Athens, Tenn.) finds a composite alternative to wood hot tub surrounds in a polyurethane (PU)-based long fiber injection (LFI) solution implemented by Romeo RIM Inc. (Romeo, Mich.).

-

JEC 2013 at first blush

CT Editor-in-chief Jeff Sloan risks some immediate reactions to his week in Paris at the JEC Europe 2013 composites trade show.

-

Waiting for $5/lb carbon fiber?

HPC editor-in-chief Jeff Sloan suggests we say goodbye to $5/lb carbon fiber and expect that composites will earn their way onto autos by saving drivers money.

-

Auto composites quest: One-minute cycle time?

Faced with high fuel prices and ever-more stringent restrictions on tailpipe emissions, automakers are taking composites into their own hands.

-

COMPOSITES 2012 Highlights

As ACMA’s annual conclave convened in North America’s gambling capital, show exhibitors and attendees placed their bets on better days.

-

Spare wheel well: Functional integration

Gas-assist injection molding enables one-piece, one-shot thermoplastic composite/metal hybrid.

-

SPE ACCE 2011: Growing again

The Society of Plastics Engineers’ 11th conference on automotive composites fields a top slate of speakers and attracts its largest crowd.

-

On the road again

CT's editor-in-chief Jeff Sloan offers a quick review of doings at this year's SPE Automotive Composites Conference & Exhibition, recently presented in Troy, Mich.

-

UBSs: Coming to North America

Common in Europe and Asia, the composite underbody shield might finally catch on in the U.S. and Canada.

-

In-mold alternatives to postmold decoration

CT reviews viable, versatile technologies that reduce the time and cost of finishing composite parts.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

COMPOSITES+POLYCON 2009 Showcase

Despite the deepening recession, composites pros returned to the show in its new time slot to explore the wealth of products and services collected here.

-

What's new in automotive front-end modules?

Composite and hybrid composite/metal solutions reduce cost and weight and increase assembly efficiency on passenger vehicles.

-

Polyurethane long fiber technology (LFT) replaces wood in spa surround

To many consumers, the thought of a relaxing soak in a hot tub is mighty appealing — but the thought of spa maintenance, particularly replacing rotted wood in the spa's cabinet-like enclosure, probably isn't. For spa manufacturer Clearwater Spas (Woodinville, Wash.), that reality and the fact that building decorativ

-

Reinforced Thermoplastics: LFRT vs. GMT

As the suppliers of long fiber-reinforced thermoplastics and glass-mat thermoplastics battle for market supremacy, the winner is … the composites OEM.

-

Engineering Insights: BMC Creates New Dimensions in Underhood Apps

Specially formulated material enables production of high-tolerance automotive engine air intake component.