Stratasys software streamlines design-to-3D printing process

The company’s Advanced FDM software reportedly eliminates CAD-to-STL conversion, speeding part processing.

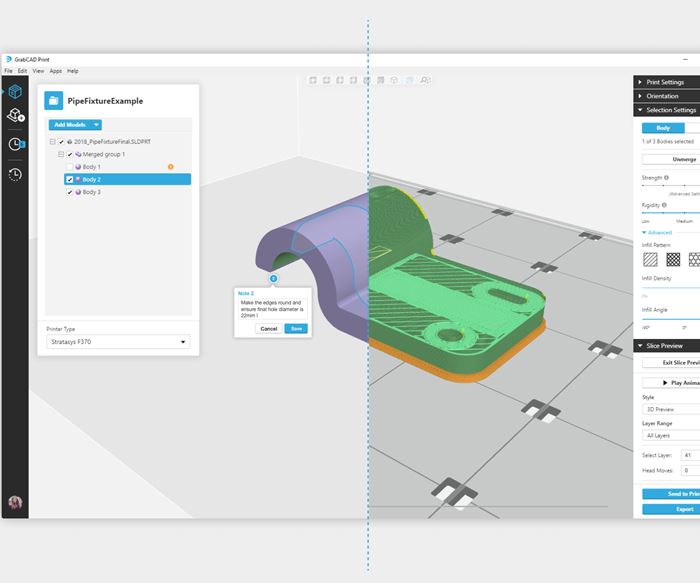

Stratasys (Eden Prairie, Minn., U.S.) has launched an Advanced FDM feature for its GrabCAD Print 3D printing software. The feature has been designed to eliminate CAD-to-STL file conversion, simplifying the overall process and resulting in quicker delivery of lightweight, strong and purpose-built parts. By avoiding CAD-to-STL conversion, users are reportedly able to work in high fidelity to quickly advance the design-to-3D print process without losing design intent, boosting both time to market and time to revenue.

The software automatically calculates 3D print tool paths after engineers select areas on native design geometry and specify design attributes directly to CAD models. No manual generation of complex tool paths is required. Users pinpoint areas of strength and rigidity, control infills, ensure sufficient material around holes with inserts and avoid seams. Since tool paths are automatically generated from model assignments, the user spends less time on part setup.

According to the company, the software also streamlines part processing by eliminating the use of multiple programs, helping to control the structure of end-use parts for markets such as automotive.

Advanced FDM is available for download with GrabCAD Print (versions 1.24 and later) and is supported on a variety of Stratasys 3D printing systems: F370, Fortus 380mc, Fortus 380mc Carbon Fiber Edition, Fortus 450mc, Fortus 400mc, Fortus 900mc and F900.

Related Content

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

.jpg;width=70;height=70;mode=crop)