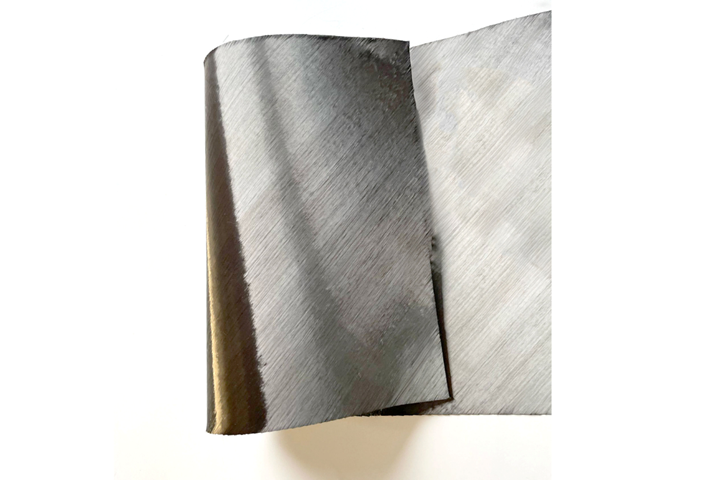

Angeloni launches non-stitched multiaxial NCF fabric option

An adhesive grants the same stability of traditionally stitched composite fabrics, making Stratos suitable for use in a range of fibers and production processes.

The Angeloni Group (Venice, Italy) is highlighting its new non-stitched multiaxial noncrimp fabric (NCF) Stratos. Traditionally, NCFs are comprised of several fiber layers arranged at different angles and stitched together. Conversely, Stratos’ layers are held by an undisclosed adhesive that the company says grants the same stability of stitching.

The NCF composite’s mechanical properties are unaltered in this process, and the fibers maintain their alignment. Moreover, impregnation is uniform and resin flow is improved. The “print through,” effect, which is eliminated, makes Stratos well suited for the production of painted components for the automotive, marine and sporting goods sectors.

Stratos can be produced using carbon, glass, aramid and natural fibers, and is suitable for RTM processing, infusion processes and prepreg production. It can be produced in weights from 100-400 g/m2.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.