Almost 20 years of development work in RTM of dry fabrics went into the design of the Icon BBCOR, Rawlings’ first two-piece bat made with infused dry braided fabrics. Source (All Images) | Rawlings

Rawlings/Easton Performance Labs (Thousand Oaks, Calif., U.S.), and its sister brands have been manufacturing composite baseball bats for more than 20 years, but one of the company’s latest offerings — the Icon BBCOR bat for high school and college players — is its first two-piece BBCOR bat design to be made with vacuum-assisted resin transfer molding (VARTM) of dry fabrics and sleeves.

“For a very long time, aluminum was king in baseball, because aluminum is extremely durable and pretty lightweight compared to wood,” explains Kevin Wilkins, R&D engineer at Rawlings. In the early 2000s, though, the growing availability and popularity of carbon fiber changed the game, offering extreme light weight, higher stiffness and a greater degree of versatility compared to aluminum. The lighter weight also enables elongation of the barrel, increasing the and optimizing hitting zone.

Combat Sports, a company that is now part of the Rawlings family of bands, began the development of one-piece composite bats around 2000, starting with RTM of dry carbon fiber fabric over an aluminum core, then shifting to an all-composite design made with carbon fiber and fiberglass sleeves. Once composite bats had been around for a few years, though, the interest in two-piece bats grew — designs which separate the barrel from the handle so less vibration is transferred to the player’s hands.

Using prepreg for a multipiece bat, though the simplest manufacturing option, was costly, and off-the-shelf prepreg materials did not always offer the needed impact toughness or other requirements. On the other hand, RTM with dry fabrics, though more cost-competitive and enabling more materials customization, was more challenging for a two-piece design, requiring multiple pieces to be molded separately and then assembled.

Nevertheless, the company continued development of both types of bats, primarily using prepreg while also focusing development efforts in RTM technology. For the latter, Rawlings and its subsidiaries have long partnered with supplier A&P Technology (Cincinnati, Ohio, U.S.) on the use of dry braided fabrics.

According to Wilkins, Rawlings has worked to perfect this combination of RTM with braided fabrics over the years, developing its own resin internally for maximum impact toughness and working with A&P on customized fabrics that ensure a soft feel and consistent wall thickness.

However, until recently, all of Rawlings’ commercial bats made using RTM have been iterations of its one-piece design — while internally the company continued working on the challenge of optimizing the process for a two-piece design.

Designing a co-molded, two-piece, infused all-composite bat

The standard development process for a new bat line is at least two years from initial designs to final rollout, explains Frederic St. Laurent, director of R&D composite engineering at Rawlings.

The main goal when starting the development process for the Icon BBCOR bat, designed for the high school and college market, was, St. Laurent says, “to create a co-molded, two-piece bat design using RTM technology, because we’ve known that RTM makes a high-performing bat, but we wanted to get the feel of a two-piece design. So there was a lot of technical development involved to figure out how to properly decouple the barrel plies from the handle plies, and use a vibration damping material in between.”

Specifically, resin flow during infusion was a challenge. To co-mold the two components in one mold, the resin needed to evenly infuse each section, but not the isolating layer in between — requiring adaptations to Rawlings’ RTM process.

Beyond technical hurdles, the design also had to meet performance requirements — and limits. Modern bats for youth and adult baseball as well as softball are required to meet a performance standard for player safety.

According to St. Laurent, there was a lot of trial and error with different A&P braids in different combinations, as Rawlings worked to tailor the performance to meet the maximum limits. Wilkins adds, “The angle of the fibers makes a huge difference, particularly in the stiffness of the barrel which affects ball speed and performance. With prepreg, you have very good control of the fibers. While using a braided material, you’re actually stretching the braid over a changing contour, which changes your fiber angle. There’s a lot of theory in it, so we had to make many prototypes to get it to perform the way that we wanted it. But thankfully, one of the advantages of RTM is its fast processing times.”

Compared to prepreg, the dry braid enabled much more tailorability to meet impact performance as well as durability requirements. The bat could also be designed with fewer — albeit thicker — plies of material, which means, St. Laurent says, there are fewer opportunities for interlaminar delamination with repeated impact. He adds, “One of the major contributing factors to a bat failing the performance standard is interlaminar separation from repeated impacts. By leveraging the unique properties of A&P’s braided materials we were able to control performance growth to develop a bat that performs at the maximum performance standard from first use.”

The resulting commercial design comprises a hollow barrel made from all carbon fiber composite braid, with a 50/50 ratio of glass and carbon fiber braid in the handle, “which allows us to fine-tune the handle stiffness to improve the feel of a batted ball,” St. Laurent says. He adds that Rawlings works with A&P Technology on customized braid fabrics for most of its bats, with specific thicknesses and fiber angles.

To manufacture each bat, dry fabrics are laid up on a mandrel, including an isolator piece between the barrel and handle. The preform (see below) is then placed into a mold. A proprietary resin system is injected into the mold cavity and cured.

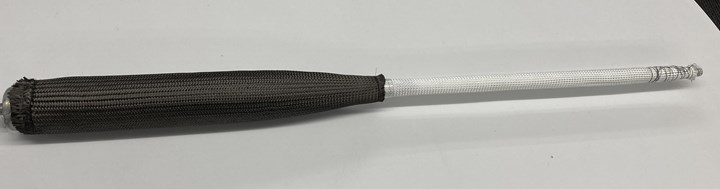

The bat (shown here as a preform before molding) comprises carbon fiber braid in the barrel for the lightest weight, and a mix of fiberglass and carbon fiber in the handle for the best vibration damping.

Wilkins explains that the combination of the braided fabric and RTM process allow for the greatest possible control of the wall thickness, and the inner and outer diameter of the barrel. “Maintaining a constant cross-section for that internal geometry, and an inside that is as smooth as the outside, is really important in bat design to maintain consistency. Regardless where a player hits on the barrel, you’re always going to get the same feel and stiffness and that’s what you want.”

Plus, “one side effect is that the sound is unique and interesting,” he adds. “Most composite bats have a little more ping and ours has more of a solid crack, which compares to a well-struck wood bat.”

Rawlings launched the Icon BBCOR all-composite bat in December 2022. After initial reviews and feedback came back overwhelmingly positive (see an example in the video below), the company had to increase the production capacity by nearly ten-fold for the bats at its manufacturing facility.

Wilkins sums up, “The 3D braided fiber shape, the resin we developed and being able to mold the two-piece design in a way that we can control the performance with the wall thickness all adds up to a good marriage of attributes that give us a unique, great-performing bat.”

Related Content

CSub delivers one-piece composite truss bridge in Norway

EPC supplier has fabricated, transported and delivered a 42-meter composite bridge intended for pedestrians and bicyclists.

Read MoreNovel woven UD fabrics are designed for versatility, reliability

CAMX 2024: Zoltek introduces PX35UD0300EPW and PX35UD0600EPW, carbon fiber fabrics providing easy handling that have the potential to meet the evolving needs of composite applications.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreBio-inspired EV underbody panel developed by TPI Composites, Helicoid Industries

Composite underbody panel for battery pack protection, made of stacked multiaxial noncrimp fabric, will serve high-volume commercial and automotive markets.

Read MoreRead Next

Thermoplastic composite, tube-shaped preforms for large-volume manufacturing

Starting with the sporting goods and bicycle market, French startup 3DiTex targets its continuous preforming system for thermoformable, thermoplastic composite tubes in complex geometries.

Read MoreWatersports manufacturer diversifies into new markets, processes

CW Top Shops honoree Cobra International reflects on its growth over 45+ years, as well as current work expanding its automotive and UAV capabilities, increasing energy efficiency and new SMC production lines.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)