Thermal Mapping Application digitizes GMI Aero hot bonder console

The TMApp enables operators to track and visualize the temperature field during composite repair or manufacture in real time using Anita 4.0 and Anita EZ bonding/repair bonder solutions.

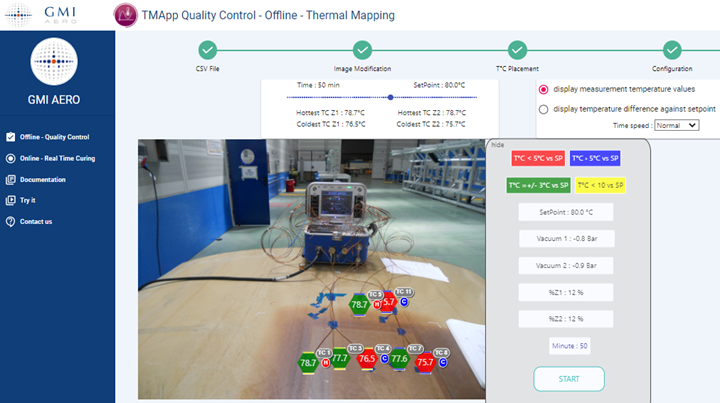

After “hexagons” appeared automatically on top left, according to the T/C used during curing, the operator was able to drag and drop them according to actual T/C positions. Photo Credit, all images: GMI Aero

Anita 4.0 is a smart, efficient and compact hot bonder solution offered by GMI Aero (Paris, France) for the bonding or repair of composite aircraft structures. The equipment is accompanied by a variety of Network Applications, or NetApps, to facilitate repair monitoring, transfer of curing data and reporting, support equipment fleet management and remote maintenance. It also enables virtual training and development of digital and physical repair twins. The first NetApp which is now fully operational is the Thermal Mapping Application — TMApp — addressing Anita 4.0 and Anita EZ (smart patch repair bonding console).

Complex repairs or thermal mapping trials require efficient correlation of temperature measurements versus T/C placements (i.e., T/C topology). TMApp is reported to facilitate repair via temperature mapping by overlaying T measurements “on” the parts (i.e., projecting the T/C measurements over a photo of the repair).

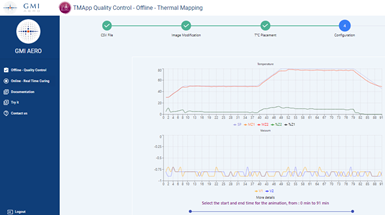

While the cycle is running (online), or in quality control (offline), the operator can take a picture, upload the photo and the corresponding .csv file onto TMApp, drag and place the predefined T/C symbols on the desired topology and see the evolution of the cycle on the picture. Absolute T values or difference to set point can be projected. In this way, operators are able to track and visualize the temperature field during repair or manufacture in real time.

GMI Aero says TMApp can be operated either through a bonder screen or on a computer/smart phone connected to the GMI cloud server via the internet. Tailored solutions can be also developed, such as connection to privately owned data clouds, or building a definition of alarm thresholds with color codes, so as to better understand the thermal behavior of the composite repair.

Learn more about TMApp here.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

.jpg;maxWidth=300;quality=90)