VR system now compatible with 3DEXPERIENCE platform

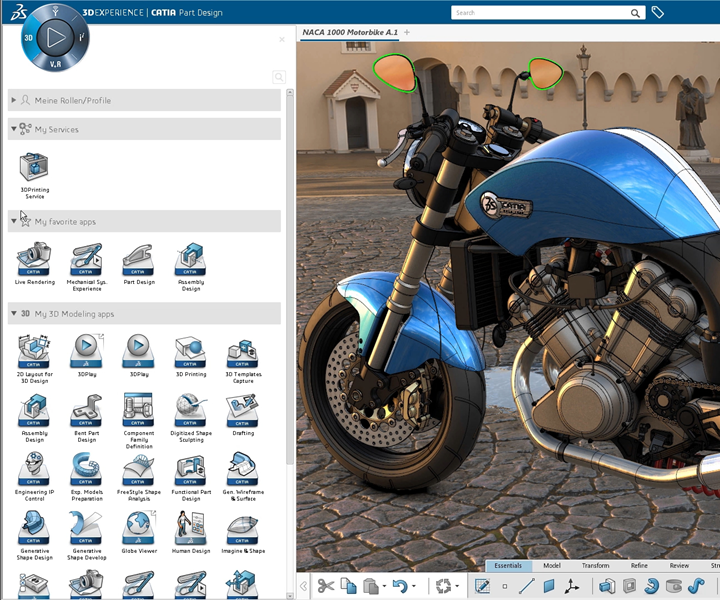

VRgineers’ XTAL virtual reality (VR) system is now compatible with Dassault Systèmes’ 3DEXPERIENCE platform.

Source | VRgineers

VRgineers’ (Marina Del Ray, Calif., U.S.) XTAL virtual reality (VR) system is now compatible with Dassault Systèmes’ (Waltham, Mass., U.S.) 3DEXPERIENCE platform, including applications CATIA, SOLIDWORKS, ENOVIA, DELMIA and SIMULIA.

The addition of 3DEXPERIENCE compatibility enables engineers to get the most out of both software systems, VRgineers says, without having to invest in additional powerwall, projection systems and cluster infrastructur

The added software support is said to enable engineers to utilize a powerful VR solution capable of total immersion for the powerful 3DEXPERIENCE platform, instead of being required to invest in a costly Powerwall, projection systems and cluster infrastructure. According to the company, XTAL offers high resolution and an excellent optical system.

With immediate support for all non-administrative applications on Dassault Systèmes’ 3DEXPERIENCE platform, XTAL will initially enable basic VR functionality, meaning full control of navigation, measurements, sections and more.

“With its ultra-high resolution visuals and peripheral vision-filling field-of-view, XTAL allows users to make better decisions in color and trim, because fine material details can be clearly seen and evaluated. Our clients also see a benefit in perceived quality reviews where gap measurements and tolerance simulations are judged based on their effect on the subjective, perceived build quality of a product,” says Marek Polčák, VRgineers co-founder and CEO.

Related Content

-

Siemens Gamesa, Airborne develop automatic preforming robot system for offshore wind blades

Danish-funded ALMA project furthers collaboration, adds new functionality, advanced sensor systems and digital twinning for reduced man-hours, waste and cost per blade.

-

Adaptive composite elements for building facades exhibited at JEC World 2023

University of Stuttgart institutes use carbon and glass fiber composites, robotic fabrication, biomimetic design and digial twin/control to demonstrate adaptive facade elements for future buildings.

-

IMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

.jpg;width=70;height=70;mode=crop)