Adaptive composite elements for building facades exhibited at JEC World 2023

University of Stuttgart institutes use carbon and glass fiber composites, robotic fabrication, biomimetic design and digial twin/control to demonstrate adaptive facade elements for future buildings.

Based on the ITECH Research Demonstrator (top left), The University of Stuttgart Institute for Textile and Fiber Technologies (ITFT) will exhibit its “Adaptive FRP elements for facade shading” demonstrator (bottom right) in the Building & Industry Innovation Planet at JEC World 2023. Photo Credit: University of Stuttgart

The University of Stuttgart’s (Stuttgart, Germany) research demonstrator “Adaptive FRP elements for facade shading” has been selected as an interactive exhibit in the Building & Industry Innovation Planet at JEC World 2023 (April 25-27, Paris, France). Movement (bending of the flap up to 90°) is activated by cushions integrated asymmetrically into the fiber-reinforced polymer (FRP) composite laminate. Visitors at JEC will be able to pressurize the cushions in the demonstrator themselves via a foot pump.

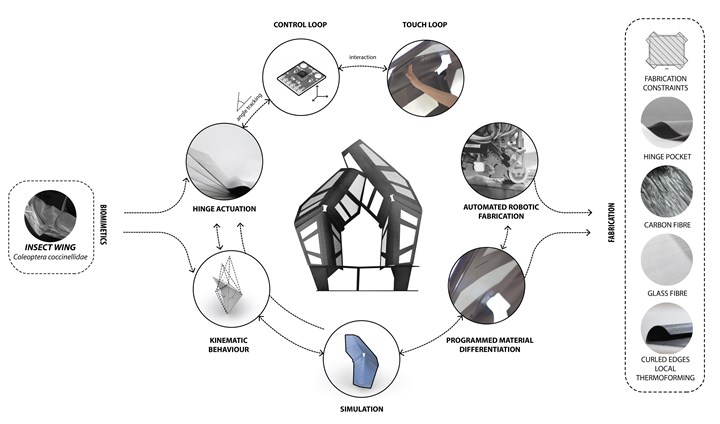

The ITECH Research Demonstrator showcased adaptive facade elements using carbon and glass fiber-reinforced composites, robotic tape laying, biomimetic design, digital kinematic analyses and computer control with a digital twin to showcase future building technology. Photo Credit: University of Stuttgart ITECH Research Demonstrator

This exhibit at JEC World 2023 is derived from the ITECH Research Demonstrator developed in 2018-19 by the Institute of Building Structures and Structural Design (ITKE) in collaboration with the Institute for Textile and Fiber Technologies (ITFT) and the Institute for Computational Design and Construction (ICD). That demonstrator comprises two folding components — one 1.7 x 3.0 meters tall, the other 1.7 x 2.5 meters tall — with a total weight of 23 kilograms per element. The laminates for the two elements were manufactured by robotic tape-laying of up to eight simultaneous tapes made from carbon and glass fiber-reinforced polyamide (PA).

With a maximum actuation pressure of 0.8 bar in the horizontal hinges and 0.4 bar in the vertical hinges, a folding angle of nearly 80° can be achieved in the two composite components. This movement can be initiated via two different means.

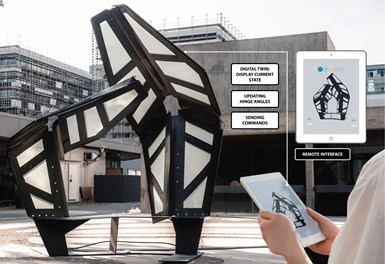

Two different means of interaction. Conductive carbon fiber in the lamainates enable parts to be touch sensitive or movement can be controlled by a mobile and web-based interface. Photo Credit: University of Stuttgart

A user can directly interact with the adaptive FRP elements through the conductivity of the carbon fibers in the composite laminates, enabling parts of the pavilion to be touch sensitive. When a user taps the structure in locally defined areas, opening and closing of the adaptive composite elements can be triggered.

A second mode of interaction is enabled through a custom mobile and web-based user control interface, allowing a user to activate and control the motion of the demonstrator via smart phone or tablet PC. The interface simultaneously visualizes a real-time 3D model digital twin representing the current folded or unfolded state of the composite structures.

ITECH Research Demonstrator 2018-19 from itke on Vimeo.

Read more about this project.

The ITECH Research Demonstrator and its associated exhibit at JEC World 2023 serve as a proof-of-concept, representing the possibilities of achieving adaptive architectural structures composed of FRP composite laminates with compliant hinge zones and integrated pneumatic actuators. These demonstrators investigate the possibilities of direct interaction between the built environment and its inhabitants through active control and real-time communication.

They also demonstrate the power of biomimetic design coupled with the integration of computational design, simulation and composite fabrication processes while highlighting the innovation potential of an interdisciplinary research and development environment.

Related Content

Composites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreNew standard specification supports non-metallic FRP rebar

ASTM International standard D8505 enables further integration of FRP rebar into infrastructure applications.

Read MoreFiberglass conduit manufacturer grows into new products, infrastructure applications

Texas-based Champion Fiberglass, a five-time CW Top Shops honoree, expands its success in the fiberglass composite conduit market into new applications and products, looking toward future automation and sustainability initiatives.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More