Waygate Technologies launches fully connected ultrasonic flaw detector

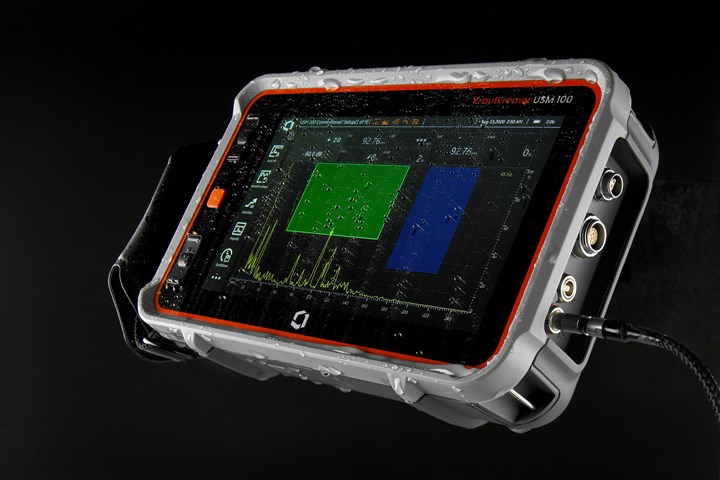

The customizable, handheld Krautkrämer USM 100 sets new standards in ergonomics, connectivity and ruggedness for composites inspection requirements, such as complex wave propagation and high attenuation.

Photo Credit: Waygate Technologies

Waygate Technologies (Huerth, Germany), a Baker Hughes business and a company offering nondestructive testing (NDT) solutions for industrial inspection, unveils the Krautkrämer USM 100, a handheld ultrasonic testing

(UT) device which takes accurate and repeatable ultrasonic inspections. In addition to optimized UT capabilities, the device is said to set new standards in ergonomics, connectivity and ruggedness for users aiming to increase overall efficiency in quality control.

Enabling operators to increase both the amount of inspections as well as the efficiency of their testing has been a guiding principle for Waygate Technologies’ engineers. As a result, user friendliness is deeply embedded in the DNA of the Krautkrämer USM 100. It presents operators with a modern and intuitive interface with smartphone-like functionality, which additionally reduces training time. The 7-in, high-resolution LCD display is glove compatible and can be used under any lighting and weather conditions. Its low weight, various carrying options and the ability to switch between left- or right-handed operations further contribute to its well-balanced ergonomics.

The USM 100 also offers enhanced digital features such as cloud-based data and fleet management, remote calibration and the ability to customize the device with apps available on the inspectionworks.com public app store. Thanks to its connectivity options, processes and reports can be streamlined and inspection data can more easily be accessed, shared and analyzed. According to the company, this results in greater testing transparency and, ultimately, in better product quality.

Boasting an IP67 rating and a drop- and vibration-tested design, the Krautkrämer USM 100 can reportedly withstand very tough conditions

and can be used for a broad spectrum of industrial inspection applications;

its software and hardware capabilities make the device ideal for weld inspection where cross-segment requirements and a variety of materials are the main challenges. It also offers dedicated features to meet composites inspection requirements, such as complex wave propagation and high attenuation. Finally, its ergonomics make it the ideal solution for physically challenging applications, such as corrosion and railway inspection, where access to the inspection site is difficult or the operator is required to move permanently between different locales.

The Krautkrämer USM 100, now available for order, comes complete in a rugged, airtight case.

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Radalytica advances multimodal 3D robotic scanner for composites, future aircraft inspection

Radalytica continues to develop its RadalyX nondestructive testing (NDT) system, merging diverse imaging methodologies for inspection in laboratories to aircraft hangars.

-

Xnovo Technology, Exciscope introduce X-ray tensor tomography technique

Through a strategic partnership, the companies introduce the FiberScanner3D module, dedicated to bringing more rapid, reliable and robust fiber structure characterization methods to lab settings.

.jpg;maxWidth=300;quality=90)