Xnovo Technology, Exciscope introduce X-ray tensor tomography technique

Through a strategic partnership, the companies introduce the FiberScanner3D module, dedicated to bringing more rapid, reliable and robust fiber structure characterization methods to lab settings.

Advanced X-ray imaging solutions company Xnovo Technology ApS (Køge, Denmark) has announced a strategic partnership with Sweden-based Exciscope AB (Sollentuna) with the goal of introducing what the company claims to be the world’s first laboratory-based X-ray tensor tomography technique — tensor tomography being a method for mapping the 3D orientation of microstructures over an extended macroscopic volume. Branded FiberScanner3D, the module is made available on the Exciscope Polaris platform.

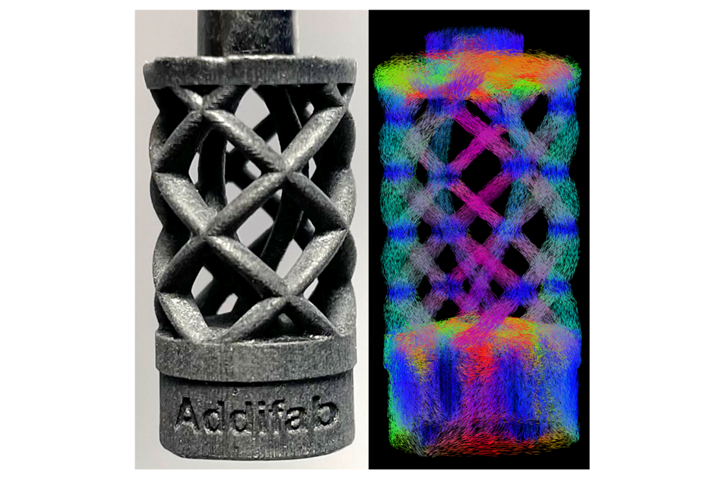

FiberScanner3D, the result of collaborative innovation with the Paul Scherrer Institute (PSI) in Switzerland, uses patented grating technology to enable nondestructive 3D anisotropic structure characterization and analysis of fibrous samples, beyond the imaging resolution limits of conventional X-ray computed tomography (CT) systems.

This technology provides access to fiber orientation and fiber alignment information without directly resolving the underlying microstructures. As a result, it opens new horizons for characterizing large-scale samples and production components, as well as for assessing their mechanical performance, and for empowering the predictive design of materials.

With applications spanning the manufacturing of sustainable materials like natural and synthetic fiber composites, to biological systems exhibiting highly anisotropic structures, Xnovo Technology says that FiberScanner3D represents a significant leap forward in analytical imaging methods. Notably, it brings X-ray tensor tomography out of synchrotron imaging facilities and into the laboratory, expanding its accessibility and applicability.

“Exciscope is committed to delivering world-leading lab-based phase-contrast imaging solutions,” Lars Romson, CEO of Exciscope, says. “Our collaboration with Xnovo is enhancing analytical capabilities for our Exciscope Polaris platform that align with the evolving needs of our customers in biomedical research, materials science and beyond.”

“Xnovo excels at bringing synchrotron-level imaging methods to the lab, and our partnership with Exciscope is yet another testament to our commitment,” adds Erik Lauridsen, CEO and founder of Xnovo Technology. “FiberScanner3D has the potential to bring materials science into a new stage of rapid, reliable and robust fiber structure characterization.”

Related Content

-

Robotic NDT inspection solutions, services enhance multitasking capabilities

CAMX 2024: Matec Instrument Companies Inc. presents its range of nondestructive ultrasonic testing technologies, including robotic inspection systems for increased efficiency and reduced physical strain.

-

Laser NDT, DIC systems demonstrate optimized noncontact composites inspection

CAMX 2024: Dantec Dynamics is presenting three of its laser shearography NDT and DIC devices, geared toward reliable measurement results.

-

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.