Search Results

Showing 151 – 160 of 2581 results

High-pressure gas storage vessels represent one of the largest and fastest-growing markets for advanced composites, particularly for filament-wound carbon fiber composites. Although they are used in self-contained breathing apparatuses and provide oxygen and gas storage on aerospace vehicles, the primary end markets are for storage of liquid propane gas (LPG), compressed natural gas (CNG), renewable natural gas (RNG) and hydrogen gas (H2).

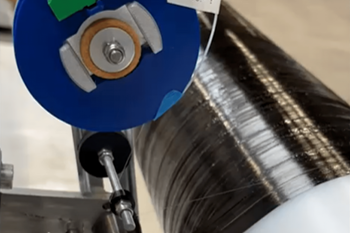

Filament winding is a specialized technique used in composite manufacturing, involving the precise and automated winding of continuous fibers onto a rotating mandrel or mold. This method allows for the creation of strong and seamless structures, optimizing the alignment and orientation of the fibers to meet specific design requirements. Filament winding is employed in producing cylindrical or conical composite parts, such as pipes, pressure vessels, and aerospace components, enabling engineers to tailor the strength, stiffness, and performance characteristics of the final product.

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

The wind energy market has long been considered the world’s largest market, by volume, for glass fiber-reinforced polymer (GFRP) composites — and increasingly, carbon fiber composites — as larger turbines and longer wind blades are developed, requiring higher performance, lighter weight materials. The outer skins of wind and tidal turbine blades generally comprise infused, GFRP laminates sandwiching foam core. Inside the blade, rib-like shear webs bonded to spar caps reinforce the structure. Spar caps are often made from GFRP or, as blade lengths lengthen, pultruded carbon fiber for additional strength.

Supply of E-glass, carbon fiber, core and fabric kit, consumables and component to generate €100 million turnover for the Metyx Group.

Pursuit of the development, construction, operation and maintenance of the first floating offshore wind farm off the coast of Washington State could further U.S. offshore energy record.

Three-day hands-on workshop from June 11-13 in Leuven, Belgium, will equip participants with a better understanding of fiber optic sensing technology for digital manufacturing of composite tanks.

Proposed lease stipulations would prioritize workforce training, domestic supply chain development, fishery protection and community engagement.

NREL researchers elicited more than 140 professional opinions concerning 2035 expectations, noting onshore wind turbines reaching 130 meters and plant sizes up to 1,100 MW.

Industrial-scale blade recycling plant setup in Navarre, Spain is to enable the energy transition by recovering composite wind turbine blade components and considering their reuse.

Germany, Belgium, the Netherlands and Denmark cooperate to increase wind capacity, expand large-scale energy hubs and explore green hydrogen, all of which will affect carbon fiber demand.

The Florida-based manufacturer began its nacelle exporting operations during the pandemic. Now, supporting GE Renewable Energy, Blue Wind strives to surpass the mark of 500 nacelles in 2022.

Second U.S. facility and several new supplier facilities are intended to build economic, employment and environmental sustainability in the U.S.

The company aims to grow product portfolio and market for wind energy technologies such as a modular blade joint and foundation solution.