Additive Manufacturing

Satellite deployer redesign supported by 3D-printed composites

A Scottish technology company employs additive manufacturing and CRP Technology composite materials for a lighter, more manufacturable PocketQube deployer.

Read MoreAscent Aerospace invests in large-format AM machine

The LFAM machine will enable fabrication and delivery of production-ready fixtures and molds at significantly reduced lead-times.

Read MoreComposites speed concrete facade fabrication

The 45-story One South First building, on the 11-acre Domino Park campus in Brooklyn, N.Y., features a geometrically complex concrete facade made, in part, with composite molds fabricated using large-format additive manufacturing.

Read MoreHyperjoint: additive metal + composites = stronger, tougher joints

Eliminates drilling holes with lap shear 60% higher than bolted joints and almost twice that of bonded joints.

WatchSpaceAM announces preliminary lineup for September event

A conference and exhibition highlighting the use of advanced materials in space technology is scheduled to take place Sept. 15-16, 2020 in Leicester, U.K.

Read MoreCFIP reinforces material with continuous carbon fibers post-process.

Continuous Fiber Injection Process (CFIP) technology works with additive manufacturing to strengthen plastics, metals and ceramics, creating complex-shaped-composites and high-strength joints.

Watch9T Labs recognized as finalist for Swiss startup award

The Swiss carbon fiber composite 3D-printing startup is one of five finalists for the Prix Strategis 2020 competition.

Read MoreJEC Group announces 2020 Innovation Awards winners

The 13 winners were announced during a virtual ceremony on May 13.

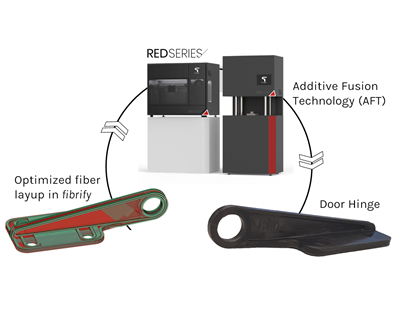

Read More9T Labs, Arkema present new manufacturing approach for small aerospace parts

The companies demonstrate cost-competitive series production of structural composite parts using carbon fiber/PEKK materials and additive manufacturing.

Read MoreThermwood's LSAM 1010 offers lower-cost, walled large-scale additive option

The LSAM 1010 uses the walls from the company’s larger LSAM systems with the gantry, control and sub-systems from the similarly-sized LSAM MT.

Read More

.jpg;maxWidth=300;quality=90)