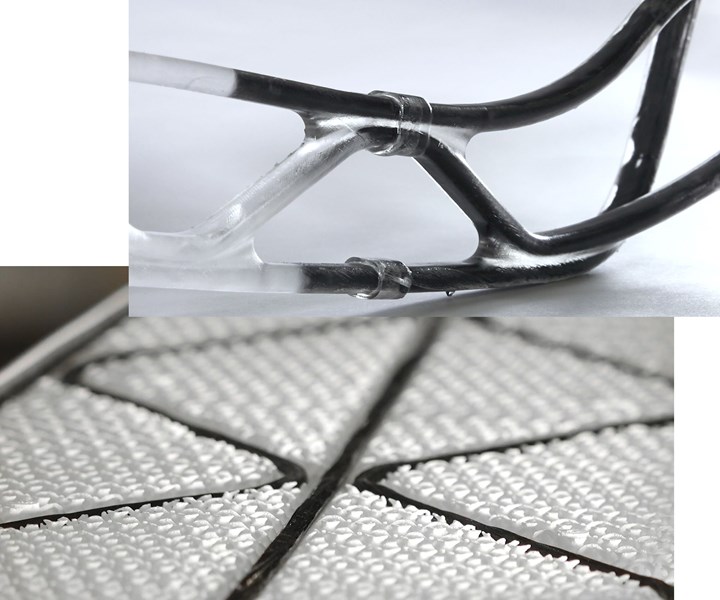

CFIP reinforces material with continuous carbon fibers post-process.

Continuous Fiber Injection Process (CFIP) technology works with additive manufacturing to strengthen plastics, metals and ceramics, creating complex-shaped-composites and high-strength joints.

CFIP (Continuous Fiber Injection Process) enables parts manufactured by 3D printing to be reinforced with continuous carbon fibers, increasing their strength while reducing weight. The technology has been developed and patented by Eurecat (Barcelona, Spain), see “Advancing thermoplastic composites and RTM for Clean Sky 2 in Spain”.

“This is a new post-processing system based on injecting continuous reinforcement fibers, such as carbon fiber, into parts manufactured by 3D printing or other types of technology,” says Marc Crescenti, head of Eurecat’s Advanced Simulation line and lead developer. “The fact that we strengthen the part by means of a post-process method, and not during the manufacturing process itself as other technologies on the market do, brings truly disruptive advantages.”

These advantages include freedom in placing the reinforcement fibers and following complex routes created digitally. This also provides a way to actualize the organic shapes output by generative design tools. “This means we can align [fibers] in the most efficient directions and further enhance mechanical performance,” Crescenti adds. CFIP can also strengthen other materials, including plastics, metals and ceramics, he explains, “which makes it possible, for example, to manufacture a titanium part strengthened with continuous carbon fibers.”

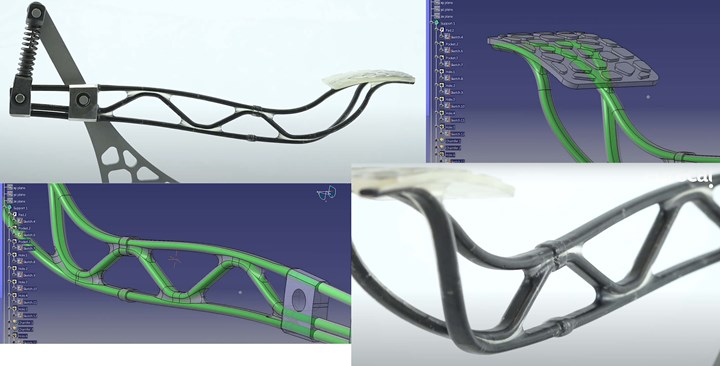

Brake pedal made with continuous carbon fiber by EURECAT using its Continuous Fiber Injection Process (CFIP). Source | EURECAT

CFIP also affords the option of integrally joining different parts with fiber continuity between them, thus providing very high-performance joints. This allows for multi-material and multi-process structures by selecting the most efficient material and process based on the requirements in each area of the structure. This technological solution has been used in several case studies for aerospace, automotive and sporting goods applications. One example is a brake pedal that Eurecat has developed by integrated joining of different materials and processes.

CFIP has been recognized with multiple awards, including the Best International Solution Award for best additive manufacturing technology by the global innovation network association IASP (Málaga, Spain) and the award for best solution in new materials presented by the IN(3D)USTRY fair. The technology was also presented at the TCT conference produced by TCT magazine as part of the Formnext international additive manufacturing event.

About Eurecat

Eurecat, Technology Centre of Catalonia, brings together the expertise of 650 professionals to serve more than a thousand companies. Eurecat is involved in 160 R&D projects, both national and international, with high strategic value and has 88 patents, seven spin-off technology companies and 11 R&D facilities in Catalonia. More information www.eurecat.org.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

TPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.