Aerospace

Collins Aerospace ramps up electric motor development for Airlander 10 airship

Collins Aerospace completes design review and begins fabrication of a 500-kilowatt electric motor for the composites-intensive aircraft, with flight qualification testing to occur in 2023.

Read MoreHenkel develops REACH-compliant structural adhesive for aircraft interiors

FST-certified Loctite EA 9365FST reinforces and bonds thermoplastic and thermoset substrates and can serve as a matrix resin on fiberglass to strengthen the thin walls of thermoplastic assemblies

Read MoreTurkish Aerospace earns spot in Boeing Premier Bidder Program

The program recognizes and rewards consistently high-performing suppliers and increases a company’s opportunities and visibility within the industry.

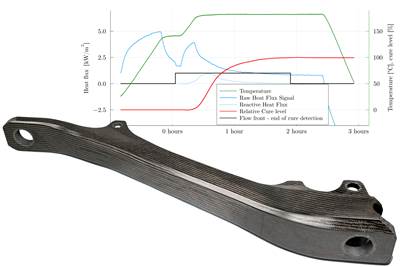

Read MoreSpeeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

Read MoreSolvay supplies composites, adhesives, technical support to Novotech Seagull aircraft development

Solvay supports the composites-intensive UAM platform with its aerospace-qualified MTM 45-1 and CYCOM 5320-1 resin systems in preparation for a flight in late 2021.

Read MoreVeelo Technologies wins award extension to enhance composite solid rocket motors

Veelo Technologies will continue to leverage its composite materials and technologies to meet Phase II program goals.

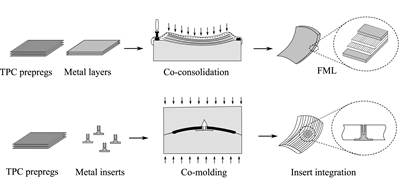

Read MoreTPRC publication studies the effects of grit-blasting on titanium-thermoplastic composite joints

Researcher Vanessa Marinosci studies the correlation between mechanical performance and titanium surface morphology of co-consolidated Ti6Al4V-C/PEKK joints.

Read MoreBieglo Group thermoplastic polymer supports project to 3D print structures on the moon

High-performance Aurum resin, combined with regolith material, will be used to create a printing material mixture that holds up under the harsh lunar environment.

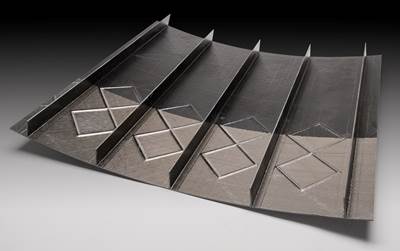

Read MoreRocket engine thrust frame proves a strong candidate for composites conversion

The engine thrust frame of a space launch vehicle, located at the bottom of a rocket stage, joining fuel tanks to engines, must deliver strength and stiffness across a range of temperatures — cost-effectively.

Read MoreSolvay launches adhesive and surfacing technologies for the aerospace industry

New AeroPaste and BR 179 adhesive and surfacing technologies are expected to increase part assembly, processing efficiency for aerospace manufacturers.

Read More