ATL/AFP

Cevotec now offers tapes for AFP/ATL

Cevotec’s cevoTape carbon fiber tape for automated placement processes is now commercially available.

Read MoreThermoplastic composite demonstrators — EU roadmap for future airframes

There is a TPC development roadmap in Europe, supported by Airbus and a variety of aerospace consortia, and involving almost every major aerostructures supplier in Europe.

WatchCevotec dry-fiber bindered tape available for automated placement

Manufacturer of SAMBA automated placement systems offers high-quality material aimed to make series CFRP production economical for non-aerospace applications.

Read MoreZero-defect manufacturing of composite parts

ZAero project aims for 30-50% boost in productivity via inline AFP inspection, simulated part performance and decision support tools.

WatchDriving down costs: Technologies to follow in 2018

Cost drives most decisions about composites use, but most innovation now focuses beyond material cost.

Read MoreTrelleborg finalizes Automated Dynamics acquisition

Automated Dynamics specializes in the development of customized automated fiber placement (AFP) solutions for high-performance composite parts and structures.

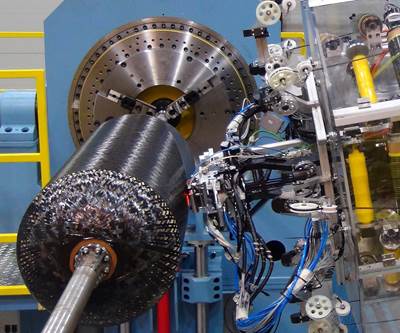

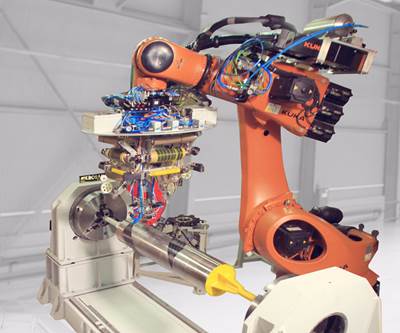

Read MoreMikrosam launches hybrid AFP & FW solution for composites production

The hybrid work cell integrates the advantages of filament winding (FW) and automated fiber placement (AFP) technologies.

Read MoreAutomated manufacturing solutions from Airborne

I had the chance recently to interview Marcus Kremers, chief technology officer of Airborne International (The Hague, Netherlands), who told me about his company’s growing smart automation initiatives for its customers.

WatchMikrosam expands into North America

Macedonia-based Mikrosam will partner with New Jersey-based Composites Automation LLC to sell its composites automation system into North America.

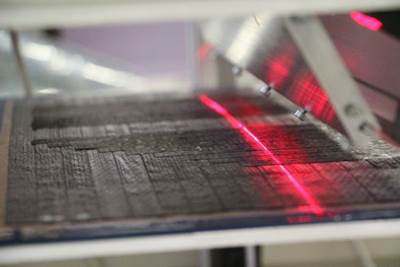

Read MoreReal-time automated ply inspection (RTAPI) system: CW’s series on automated inspection methods

More composites being used in aircraft, and the pressure for higher production rates means new technologies for automated, in-process inspection while the part is being fabricated. Groups around the world are working on this, and making great strides.

Watch

.jpg;maxWidth=300;quality=90)