Zero-defect manufacturing of composite parts

ZAero project aims for 30-50% boost in productivity via inline AFP inspection, simulated part performance and decision support tools.

The promise of automated manufacturing for composite parts in the aircraft industry has not yet been fully realized. Though the safety-driven standards for high-quality structures are understandable, they are currently being met via manual visual inspection — i.e., an inspector must stop the machine and visually inspect the layup before proceeding.

ZAero is a European Commission (EC) funded project within the Horizon 2020 research framework which aims to increase composite parts production efficiency by 30-50% via an inline, automated inspection system. But its goes even further, encompassing part simulation and decision support tools for process chain operators.

These systems are projected to produce savings of 150M€ per year if implemented in the series production of A320neo carbon fiber reinforced plastic (CFRP) wing covers. They will also resolve the inability of current quality control systems to keep up with increased aircraft production rates (60 aircraft/month) and help to achieve required productivity.

ZAero Partners

|

Project coordination and machine learning. |

| Sensors for AFP and for resin infusion flow front and cure monitoring in cooperation with InFactory Solutions. | |

|

|

Alternative ADMP technology for dry fiber AFP. Instead of placing 16 or 32 tows, it lays very wide fabric materials (e.g., woven and noncrimp fabric), placing a large amount of material in a short time. |

| Simulation of part performance from manufacturing data used in decision support tool for how to address identified defects. | |

|

Conducting manufacturing tests for data collection and building demonstration parts using dry fiber AFP and resin infusion. |

| Calibration topics related to the various measurements systems, includes standards and traceability of the measurement systems as part of the calibration process. Non-university R&D center, part of DANOBAT Group. | |

|

AFP machine integration. |

Project leader: Profactor

The idea for this project came from Profactor (Steyr, Austria), a non-university R&D center with two main activities:

- Micro and nano manufacturing

- Industrial assistance systems such a human robot collaboration (cobots) and quality assurance using machine vision and machine learning.

“We are coordinator of the ZAero project,” says Profactor manager for machine vision, Dr. Christian Eitzinger. “Essentially, the project is our idea. We have worked with the aerospace industry for a while and seen problems with quality control in production of CFRP parts. From Airbus we learned there were still issues with inspection, especially with AFP, so we had the idea of a larger project that covers the whole production process.”

The whole production process, says Eitzinger, “means starting from layup and processes that place material into a mold, to curing processes, focusing on how to integrate quality control and the resulting rework decision and process chain.”

He explains that ZAero is just one in a large cluster of projects — see 4ZDM — within the field of zero defect manufacturing, not just for aerospace but in different fields (e.g., micro-manufacturing in aerospace as well as automotive).

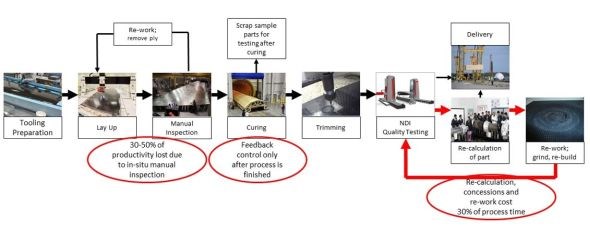

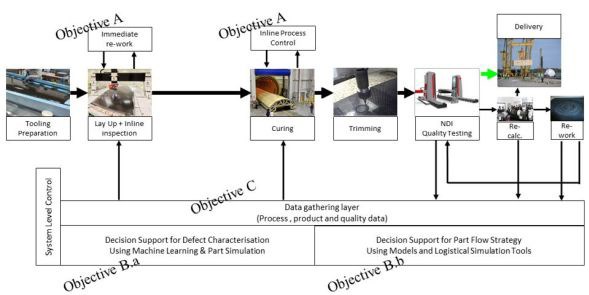

Current State of the Art (SOTA)

ZAero Solution

Project Deliverables

ZAero began in 2016 and ends in 2019. Eitzinger explains its three deliverables/main initiatives:

- “We want to replace existing manual inspection processes during fiber placement that currently create a production bottleneck. The solution is an automatic inspection system that will detect gaps, overlaps, fuzzballs and foreign object debris (FOD). In order to do this reliably, the system must have a learning component to distinguish a normal surface from one with these defects and also must differentiate between these defects.”

CFRP Production Bottleneck

|

|

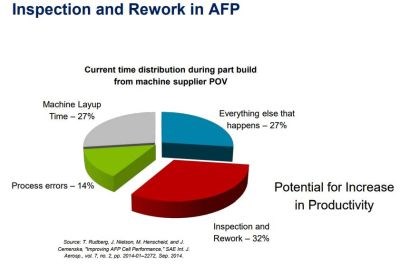

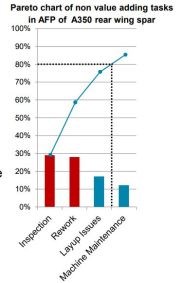

Inspection and associated rework accounts for over 30% of the part build time for an automated fiber placement (AFP) machine, according to a presentation given by Dr. Rainer Rauh, representing project partner Airbus at CW’s Carbon Fiber 2017 conference.

SOURCE: Dr. Rainer Rauh, VP platform structures, Airbus Corporate Technical Office.

- “We are also collecting sensor data during cure and trying to predict the final performance of the part.”

- “At a higher level, we are collecting all of the data from these systems in order to help the operator decide how to handle a particular type of defect. Thus, we are building decision support tools for the process as a whole. Ideally, the more the process operates and the more data it generates, the more intelligent these decision support tools will become.”

SOURCE: Profactor

Sensors and machine learning

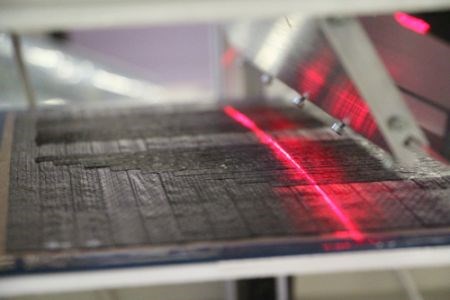

The sensors ZAero is using for layup have been developed in-house. It is also pursuing sensors developed and recently qualified by InFactory Solutions for MTorres AFP equipment. “Our experiments are currently based on dry fiber placement with MTorres and FIDAMC,” Eitzinger adds.

One challenge is that sensors need to be integrated into the machine. “But there is little space to do this in the AFP heads,” Eitzinger points out. “It requires delicate design.” Another issue is development of sensors for AFP onto curved surfaces. “In the end, it’s an economic issue,” he explains. “If you want to build a sensor to scan a surface, it has a certain depth of view. If the part curvature is high, then the area you can scan within your depth of view is smaller. If you want to scan a larger area, you need more scanners or the ability to scan in more angles (e.g., 2 images with an offset of 10°).” This would be analogous to the use of phased array transducers in large-area ultrasonic testing (UT) systems.

Though machine learning is a Profactor expertise, developing the upper level decision support technology for the ZAero solution presents certain issues. Eitzinger explains, “The standard approach when you use a machine learning system is to train the system to reach a certain level of performance before implementing it in production. To do this, we train the system offline and then “freeze” it — putting it into production with no further changes. However, with ZAero, we are pursuing a newer approach, trying to make use of the data stream from the production line to continuously improve the system’s performance. This is online training. The challenge, then, is that the system’s machine learning is changing all the time and perhaps not always in the right direction. Thus, one of the issues is how to assess and manage this online machine learning in order to keep the process chain stable.”

Simulation

This part of the project is led by Dassault Systèmes. “Their current focus is more on the layup process,” says Eitzinger. “If there are defects, what do you do? Instead of using the current set of complex rules, their approach is to acquire data from how the part is actually manufactured and use this in FEA models to predict the part’s performance. You simulate the defect using real data and predict what impact it will have. Can it stay or does it need to be removed/addressed?”

Stay tuned for our next blog on ZAero, which will include an in-depth discussion about the resin infusion flow front sensors being developed and resin state monitoring during cure.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More