Automated manufacturing solutions from Airborne

I had the chance recently to interview Marcus Kremers, chief technology officer of Airborne International (The Hague, Netherlands), who told me about his company’s growing smart automation initiatives for its customers.

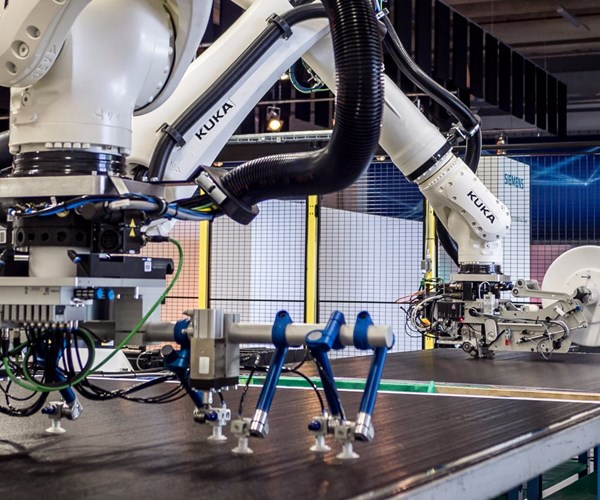

Airborne is developing smart automation initiative for customers, like this pick and place robotic solution.

When you receive the December issue of CompositesWorld magazine, you’ll see a Feature article on Industry 4.0, which looks at where the composites industry currently stands in relation to automated design and production. Because this topic is broad and growing, there just wasn’t enough room on the printed pages to include many of the innovations and companies involved. But I had the chance recently to interview Marcus Kremers, chief technology officer of Airborne (The Hague, Netherlands), who told me about his company’s growing smart automation initiatives for its customers.

If you don’t know Airborne, it is a composites part producer with about 120 employees focused primarily on space, aeronautics, maritime and the automotive industries. The maritime market sector (tidal turbine blades, ship propellers and other subsea composites) comes under the purview of Airborne Maritime (AEL in the UK), and a separate company, Airborne Oil and Gas (IJmuiden, Netherlands, Houston, TX, US and Kuala Lumpur, Malaysia), manufactures thermoplastic composite spoolable pipes for the oil and gas industry. The company is transforming itself into an automated solutions provider, using its more than 20 years of experience in advanced composite manufacturing.

For the past several years, says Kremers, Airborne has been developing a strategy to help its customers produce composites in faster, smarter, and automated ways: “We’re in the business of providing our customers high-end composite solutions, whether that means manufacturing the parts in our facility, or developing industrialization packages so that they can produce the parts themselves. Customers come to us with an idea — we help them realize that idea using our knowledge of composites and machine technology. Airborne’s focus is on high-end composite components, at high production rates at radically low conversion costs.”

It’s a three-pronged approach, according to the company, called “Prove and Move.” In the first phase, clients work with Airborne in a partnership to develop an efficient manufacturing method, and Airborne takes over part production. Phase 2 involves analysis of the part’s manufacturing process to identify quality-critical steps and develop a plan for automated and digital manufacturing, with input from equipment and software partners such as Kuka Robotics Corp. (Augsburg, Germany) and Siemens Nederland NV (The Hague, The Netherlands), respectively. Finally, production is shifted to the new, qualified automated line in Phase 3, either at Airborne’s facility, at the customer facility, or at a subcontractor’s manufacturing site. Here’s an Airborne video showing the various automation scenarios:

Says Kremers, “We have set up a Field Lab called “Digital Factory for Composites”, part of the Dutch Smart Manufacturing Initiative, to implement Industry 4.0 for composites with our partners Siemens, KUKA, TU Delft and more recently, materials supplier SABIC Innovative Plastics. This has really enabled us to better apply automation and digital manufacturing technology to our customers’ projects.”

A great example of Airborne’s approach to improving composite manufacturing productivity was recently announced (see the link to the CW story here: https://www.compositesworld.com/news/airborne-introduces-automated-kitting-solutions). It’s a fully automated process for picking, sorting and placing of composite plies, a solution that can be fully integrated with any automated flat-table, conveyor-type cutting machine to reduce cost and labor time to convert composite rolls into sorted kits. The solution was introduced this past October at the AIRTEC 2017 trade show by Kremers.

He explains that the system is built around a KUKA robot and a camera system that’s integrated with the end effector, which can be a needle gripper or suction-cup type, depending on the customer’s need and material type. As the material is cut on the table within the nesting program, with the cutting head plotting a printed code on each piece, the robot takes up the pieces in accordance with the kitting system programming, and automatically sorts them at a sorting station to create the kits: “It’s one integrated cell. No human labor is needed to create the kit. The camera records the operation, and the code on each piece, and program does the work. It provides full traceability for each kit.”

He adds that the system has the capability of much more, such as nesting and kitting for material rolls, rather than just by part: “For example, if you are working on four different shipsets of parts, each of which uses some of Material A, it is possible to nest and cut all four shipsets with Material A as one batch, which saves tremendously on material waste, given the high cost of aerospace materials. The robotic system never loses track of which piece goes in which kit.” Kremers notes that the automated kitting system is advancing the adoption of advanced and dynamic nesting software strategies, which software providers such as Plataine (Waltham, MA, US) are promoting. As noted above, Airborne can perform the kitting for the customer, or can build and install the work cell in a customer’s facility.

Many more automated applications are in process, he says, although specifics can’t be announced yet: “We are working on an end-to-end automated process flow for thermoplastic tailored blanks for aerospace, and have a low-cost, robotic multi-functional ATL cell for the prepreg that also features pick & place for local patches and ultrasonic cutting, for example.” Watch CW for more on automated manufacturing from Airborne.

Related Content

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More