Thermoplastic composite demonstrators — EU roadmap for future airframes

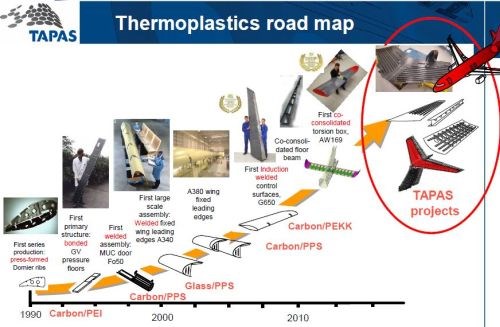

There is a TPC development roadmap in Europe, supported by Airbus and a variety of aerospace consortia, and involving almost every major aerostructures supplier in Europe.

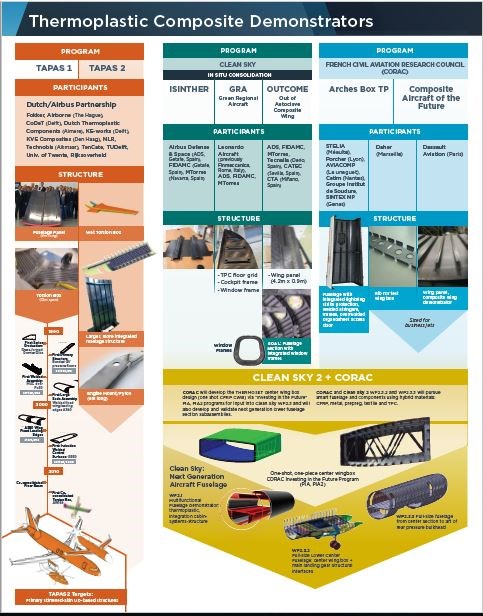

There is a roadmap of sorts for development of thermoplastic composites (TPCs) in Europe, supported by Airbus and a variety of national aerospace consortia — e.g., TAPAS1, TAPAS2 in The Netherlands and the Civil Aviation Research Council (CORAC) “Investing in the Future” program in France — as well as programs in Germany, Austria and Spain. These programs are coordinated with and feed into much larger pan-European collaborations, most notably Clean Sky (2008-2016) and Clean Sky 2 (2017-2021), which are part of the European Commission’s Horizon 2020 program (2014-2021). Note these are public/private partnership (PPP) programs deliberately organized to achieve technology readiness level TRL 6 for multiple composites and metals technologies and eventual downselection for future aircraft production. They also involve almost every major aerostructures supplier in Europe.

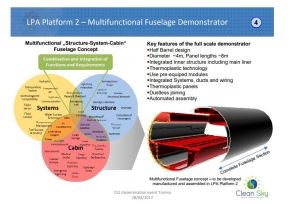

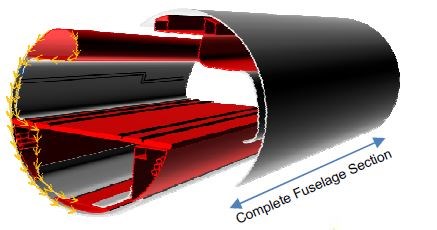

Having demonstrated co-consolidated TPC skin-stringer structures in increasingly larger sizes and complexity, these programs are now ramping to full-scale fuselage demonstrators in Clean Sky 2 including the Full-size Lower Center Fuselage (WP2.3.2), Full-size “typical” fuselage (WP2.3.3) and Multifunctional Fuselage Demonstrator (WP2.1).

The Multifunctional Fuselage Demonstrator (8m long, 2m diameter) is particularly interesting, featuring an asymmetrical, half-barrel fuselage design that will be manufactured by 2020 using thermoplastic composites. The goal is to integrate cabin, cargo and aircraft systems with the airframe in order to reduce weight and manufacturing cost while enhancing space for passengers and cargo.

|

The Clean Sky 2 Multifunctional Fuselage Demonstrator will use thermoplastic composites to combine cabin, systems and structure, enable dustless joining and faster cabin reconfiguration, reduce aircraft manufacturing cost and lead-time, and many other advanced objectives in pursuit of more sustainable aircraft manufacturing.

SOURCE: Clean Sky 2 dissemination event April 28, 2017, Torino, Italy.

In general, TPC development in France and The Netherlands has pursued a two-step approach while one-step in-situ consolidation (ISC) has been favored in Spain.

France

Coriolis Composites (Quéven, France) has been a key partner in TPC technology development. It worked with Airbus to develop robotic AFP into an industrial solution with the FlashTP machine, which demonstrated thermoplastic materials and process performance in comparison to thermoset prepreg technology and validated key developments by Coriolis and others. Flash TP is installed at the Technocampus EMC2, a research and technology transfer center located adjacent to Cetim and the Airbus facility in Nantes. This Airbus site is a leader in composites, producing the A340 keel beam, A380 center wing box (50% composite), radomes for all Airbus aircraft and the nacelle air inlets for the A340 and A380.

In addition to the Flash TP machine (see “Consolidating thermoplastic aerostructures in place, Part 1”), Coriolis AFP systems are also being used for TPC development at multiple locations in France, including Dassault Aviation (Biarritz), Daher-Socata (Nantes), STELIA (Méaulte) and Estia-Compositadour (Bayonne), as well as in Dutch TPC development at Netherlands Aerospace Center (NLR, Amsterdam) and the ThermoPlastic composites Research Center (TPRC, Enschede, The Netherlands). COMPOSITADOUR is a composite and robotics research center where Coriolis has demonstrated a TPC fuselage part with Airbus, using the largest, most powerful laser (12 kW) that Coriolis has yet provided.

At the 2017 Paris Air Show, STELIA Aerospce (Toulouse, France) exhibited a TPC fuselage demonstrator that features welded stringers and frames as well as lightning strike protection (LSP) integrated into the skin during AFP. The fuselage was developed at STELIALAB (Méaulte, France) via the “Arches Box TP” project (2015-2017), part of the “Investing in the Future” PIA, PIA2 programs organized by the French Civil Aviation Research Council (CORAC). Note that CORAC is a key part of the Clean Sky 2 WP2.3.2 and WP2.3.3 fuselage demonstrators (see graphic above). “Arches Box TP” partners included TPC and press-molding specialist AVIACOMP (Launaguet), Groupe Institut de Soudure (Villepinte, France) for induction welding technology, thermoplastics specialist SINTEX NP (Genas) which also excels in design/simulation and overmolding, and Porcher (Lyon), which supplied the CF/PEKK Pipreg used in the frames and overmolded access door. Cetim is also a partner and is shown as producing stamped stringers and/or frames in the STELIA video above.

(Learn more about the Arches Box TP project in “STELIA Aerospace develops induction welding technology” and “Porcher works with Stelia Aerospace on thermoplastic fuselage”.)

In another CORAC program, Daher (Marseille, France) has designed and built its first thermoplastic composite wing rib. Sized for a business jet, it will be incorporated into a test wing box in 2018 as part of the “Composite Aircraft of the Future” platform. Daher claims its patented technology enables TPC parts that are 35% lighter than metal equivalents, but also states these parts can be complementary to metallic or more traditional thermoset composite parts. This aligns with the Clean Sky 2 goal to investigate smart fuselage and hybrid materials concepts, including traditional carbon fiber reinforced plastic (CFRP), metal, prepreg, textile (implies out of autoclave resin infusion of dry fabric) and TPC. Daher has also produced an out of autoclave CFRP wing spar which it will install in a CORAC test cell in 2018.

The Netherlands

Highlights in TPC development here include a 12m span torsion box with “smart patches” for structural health monitoring and a 4m long fuselage panel in TAPAS 1. Both structures feature co-consolidated integral stiffeners.

In TAPAS 2, a new torsion box uses rib stiffeners co-consolidated with the AFP skin and also advances technology for the structure as a fuel tank, like the “wet wings” used in aircraft today. The TAPAS 2 fuselage demonstrator developed and produced by GKN Aerospace’s Fokker business, features fully welded frames using butt jointed orthogrid technology, like that shown at JEC 2014. The third TAPAS 2 demonstrator was produced by NLR and exhibited at JEC 2017 — a 6m-long, 28mm-thick CF/PEEK engine pylon upper spar made using AFP but consolidated in an autoclave. Note that all TAPAS demonstrators use two steps to achieve consolidated aerostructures.

NLR designed and produced the TAPAS2 program’s 3rd demonstrator — a 6m long, 28mm thick CF/PEEK engine pylon upper spar made using its Coriolis AFP machine.

SOURCE: NLR.

Spain, Germany and Austria

In Spain, FIDAMC (Getafe), using MTorres (Navarra) AFP equipment, has produced multiple wing and fuselage demonstrators — all one-step ISC — culminating in the 4160 mm x 853 mm integrally-stiffened wing panel in the Clean Sky OUTCOME program (learn more in “Thermoplastic composite wings on the horizon?”). It has also produced an integrally-stiffened CF/PEEK cockpit frame and CF/PEEK window frames, the latter to be integrated into the Clean Sky Next Generation Aircraft Fuselage WP2.3 demonstrator (see “Thermoplastic Composite Demontrators” graphic above).

FIDAMC has demonstrated stiffener-skin fuselage panels using both one-step ISC (shown here) and two-step processing using autoclave for consolidation. SOURCE: FIDAMC.

Two different fuselage panels — one produced using ISC and one using autoclave cure of AFP skin onto pre-stamped stringers — are each 1.5m long and 1m wide with 3 hollow hat stringers and less than 2% porosity. FIDAMC is now working with the German Aerospace Center (DLR, Cologne) and Aernnova (Miñano, Spain) in the Clean Sky 2 Multifunctional Fuselage Demonstrator initiative (see above).

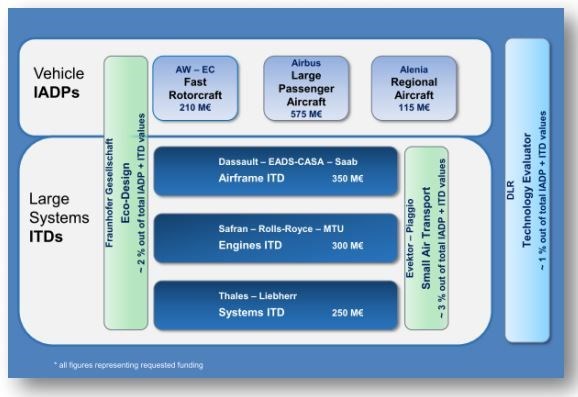

INSCAPE — In situ manufactured carbon/thermoplastic curved stiffened panel — is another TPC development program within Clean Sky 2. While the Multifunctional Fuselage Demonstrator resides within Clean Sky’s top tier of Vehicle IADPs — Innovative Aircraft Demonstration Programs, specifically the Large Passenger Aircraft (LPA) IAPD — INSCAPE sits within Clean Sky 2’s lower tier of Large System ITDs — Innovative Technology Demonstrators, specifically the Airframe ITD. Work being done here will feed into the LPA IAPD for testing.

The Multifunctional Fuselage Demonstrator described above is one of 3 full-scale demonstrators within the Large Passenger Aircraft (LPA) Innovative Aircraft Demonstration Programs (IADPs) show in the top tier. The Innovative Technology Demonstrators (ITDs) are shown on the lower tier, and include work which will feed into the LPA IADPs for testing. SOURCE: Clean Sky 2 Joint Technical Proposal

INSCAPE is led by Airbus DS (Defense and Space, Madrid, Spain) jointly with SAAB (Stockholm, Sweden) and Dassault Aviation (Paris, France). Work being done here represents the continuation of the activity developed by Airbus DS in Clean Sky 1 in collaboration with FIDAMC. INSCAPE is coordinated by the Technical University of Munich (chair for carbon composites, Munich, Germany) with FACC (Ried im Innkreis, Austria) co-responsible (jointly with Airbus DS) for the design of the curved, integrally stiffened thermoplastic part, as well as the required forming dies and layup tools. Thermoplastic tape placement equipment supplier AFPT (Dörth, Germany) is also a partner, assisting with programming and manufacturing, as is INEGI (Porto, Portugal), which is responsible for testing.

“The curved structure that was proposed by Airbus DS tries to demonstrate manufacturing capabilities dealing with curvature and tapering on stiffened panels,” explains Rene Adam, R&D director at FACC. He notes that INSCAPE’s approach is similar to FIDAMC’s in terms of stringer-skin installation and a one-step AFP in-situ consolidation process with laser heating (Fig. 4). “INSCAPE complements FIDAMC’s gantry-installed AFP for semi-flat wing panels in the OUTCOME project,” says Adam. “It addresses higher curvatures and tapering with a more flexible Kuka robot arm, a different manufacturing process for stringers, as well as different material suppliers and faster layup speeds.” He adds that this type of structure may be used in engine nacelles, fuselage doors or the tail cone section of the fuselage, and also in higher curvature structures such as leading edges, pylons, flaps or other movables.

Leading edges and Italy

“Thermoplastic leading edges are not limited to large aircraft,” points out Arnt Offringa, head of aerostructures R&T for GKN Aerospace’s Fokker business. “As an example, the Leonardo Helicopters AW169 light twin helicopter features a thermoplastic horizontal tail that has carbon/PPS thermoplastic leading edges. They feature a small front radius and ultra-thin ribs (thickness less than 1 mm).” Offringa notes that TPC was specifically requested by the customer, to provide toughness in this impact prone area. This toughness also makes it an excellent choice for thin-walled structures such as aircraft fuselages, which can then be designed with lower weights and novel design features that reduce cost.

Leonardo Helicopters is based in Cascina Costa di Samarate, Italy. Development of thermoplastic composites has continued here and in Leonardo Aircraft and brings Italy into the EU roadmap. Also a participant in Clean Sky 2, Leonardo is behind some very interesting development work that could take ISC in a different direction. Stay tuned for more details in Part 2 of my feature ”Consolidating thermoplastic aerostructures in place” in the April issue of CompositesWorld.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More