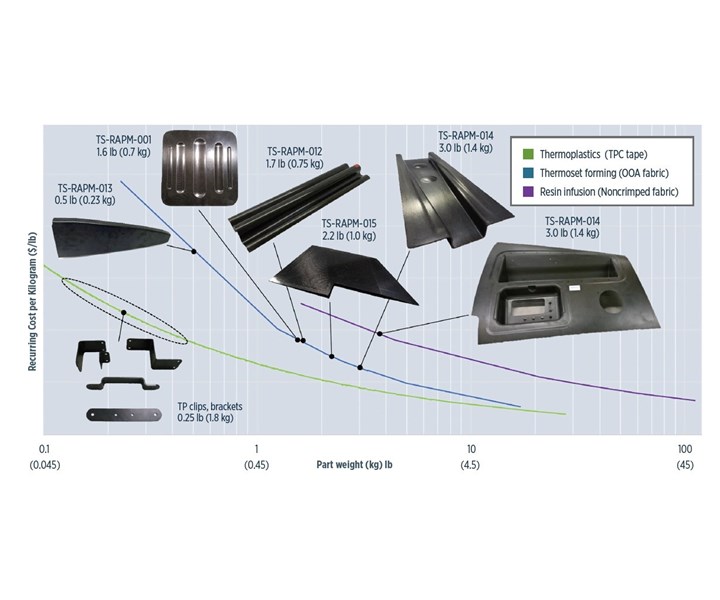

Recurring cost trends by component size

Recurring cost trends by component sizeThe RAPM subprogram within DARPA’s Tailorable Feedstock and Forming (TFF) program compiled analytical data from current/past production as well as empirical data from its own forming trials for multiple parts to generate these curves. The goal is to better understand the trade space for composite parts and processes.

Source for all images: The Boeing Co., DARPA

The Tailorable Feedstock and Forming (TFF) program was launched by the Defense Advanced Research Projects Agency (DARPA, Arlington, Va., U.S.) in 2015 to enable rapid, low-cost and agile manufacturing of small, complex-shaped composite parts for defense aircraft. This 48-month program aimed to increase the cost-competitiveness of composites in order to exploit their weight savings and resistance to corrosion and cracking versus machined aluminum. In Part 1 of this series, CW explored TFF’s vision and its Tailorable Universal Feedstock for Forming (TuFF) subprogram, which developed a short-fiber sheet material with high mechanical properties and metal-like formability.

In this article, the focus moves from feedstock to forming with TFF’s second subprogram: RApid high-Performance Manufacturing (RAPM, pronounced “wrap-em”) led by The Boeing Co. (Chicago, Ill., U.S.). The program began in July 2016 and has presented its results in numerous publications including 6 papers and two presentations at SAMPE 2019. RAPM’s goal, as explained by Boeing technical fellows and principal investigators Gail Hahn and Tom Tsotsis, is to “revolutionize the cost paradigm for small composite parts, enabling pervasive use in defense applications.”

Welcome! You’ve unlocked premium content.

“We started out with this vision of achieving aerospace performance with automotive efficiency,” says Hahn. The program worked with automotive composite materials and parts manufacturers, including Solvay Composite Materials (Alpharetta, Ga., U.S.) and SGL Composites (Ried and Ort im Innkreis, Austria), but achieving aerospace properties wasn’t always straightforward. “Although lower-temperature, rapid-cure epoxies are readily available for automotive applications, they do not come close to meeting aerospace requirements,” says Tsotsis. RAPM did use new, rapid-cure, two-part epoxies targeting aerospace-grade resin infusion parts. However, initially, the molding system at SGL could not exceed 130°C, which prevented reaching the goal of 30 minutes time-on-tool.

“Our goal was to achieve 30 minutes maximum time on tool to enable the use of a high-rate work cell to reduce system-level costs to be cost-competitive with machined aluminum,” says Tsotsis. “Within Boeing we decided that would satisfy everything we were seeing for defense applications,” adds Hahn. “Why set it here when we can get 2 to 6 minutes with thermoplastics? Because thermoplastics require even higher temperature processing with corresponding tooling constraints, and our goal is to give our supply chain plenty of options.”

As the program moved forward, it opened up to aerospace materials and manufacturers and even experimental systems, such as Solvay's XEP-2750. “We originally thought we’d be able to fully evaluate this system, as we did with CYCOM 5320-1 in our work with the DARPA program ‘Non-Autoclave Manufacturing Technology’ from 2007 to 2012,” says Hahn. Though the same degree of evaluation wasn't possible, XEP-2750 has now been commercialized by Solvay as CYCOM EP-2750 (see online sidebar “Novel prepreg for compression molding in RAPM”) and benefited from the numerous RAPM part trials and lessons learned.

“All I want is a couple of processes for small composite parts that can win against aluminum in a trade study,” says composites industry and TFF program consultant Jeff Hendrix of his goals for RAPM. So, has RAPM succeeded? CW explores the program’s efforts to manufacture hundreds of parts, comparing more than a dozen aerospace part configurations through multiple materials and processes, while pursuing methods to reduce time and cost.

Program framework

Working with key industry partners, RAPM trialed parts in three primary tracks:

- Resin infusion with HITCO Carbon Composites (Gardena, Calif., U.S.) and SGL Composites

- Thermoset prepreg forming with Solvay Composite Materials (Heanor, U.K. and Anaheim, Calif., U.S.), Fiber Dynamics (Wichita, Kan., U.S.) and Reinhold Industries (Santa Fe Springs, Calif., U.S.)

- Thermoplastic forming with ATC Manufacturing Inc. (Post Falls, Idaho, U.S.) and TxV Aero (Bristol, R.I., U.S.)

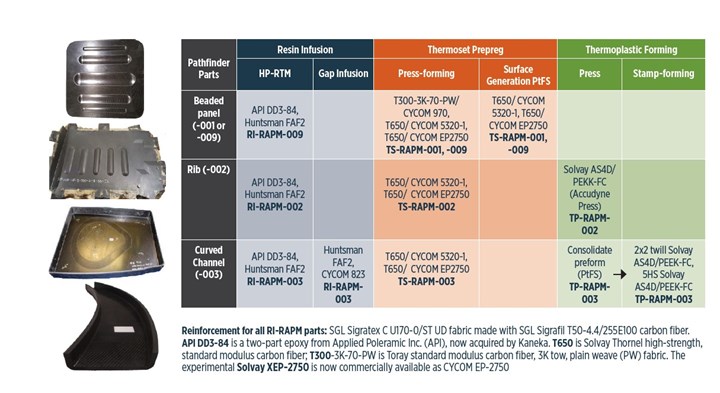

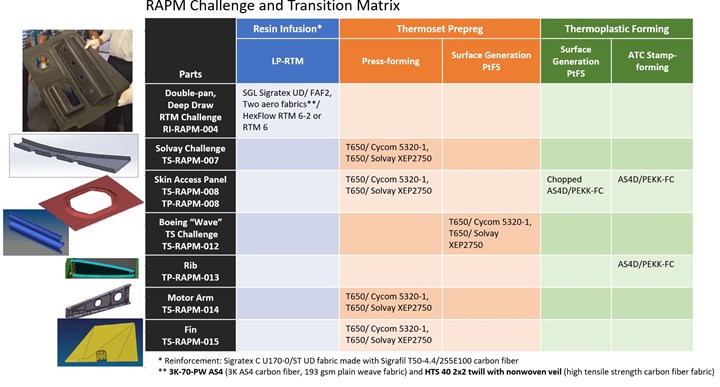

Forming trials were completed in two phases: an initial “Manufacturing Development” phase (Fig. 1) followed by subsequent “Challenge and Transition” (C&T) parts (Fig. 2) to challenge initial developments and transition candidates with potential to win against machined aluminum.

Fig. 1. RAPM manufacturing development trials

Initial forming trials comprised three main process tracks and three main part configurations designed to develop design and process guidelines for subsequent challenge and transition parts (Fig. 2).

Fig. 2. RAPM challenge and transition trials

Selected parts from the initial phase were defined for one or more processes to challenge initial developments and transition candidates with potential to win against machined aluminum.

Manufacturing development trials used three primary part configurations: beaded-panels (there were two types), a rib with pad-ups (ply build-ups) and a curved C-channel. These incorporated features common to aerospace parts that can cause manufacturing challenges: the beaded panel had multiple out-of-plane features plus pad-ups, pad-downs and a vertical edge; the rib panel had a pad-up with multiple 90-degree edges as well as a joggle in one of the edges; and the C-channel had a different inside and outside radius, varying curvature in the flanges and significant ply drops in the web.

The goal was to develop design and manufacturing guidelines for each of the three tracks. “It didn’t look sexy doing these first trials,” recalls Hahn. “But they helped determine acceptable radii and part geometries that would produce parts without unwanted fiber distortion as well as optimal combinations of parameters such as applied tension, temperature, pressure and time on tool.”

All three RAPM material and process tracks included trials using a Surface Generation (Rutland, U.K.) Production to Functional Specification (PtFS) pixelated-heating control and tooling system (see online sidebar “RAPM development with PtFS”), located at Boeing R&T in St. Louis, Mo., U.S. “This came about because we were looking for a work cell that could accommodate all three types of materials/processes in a flexible rate environment,” says Hahn. “We were able to explore different temperature control approaches and costs.” The Boeing PtFS cell has a maximum temperature of 440°C, a clamping force of 150 tons and an effective part volume of 750 by 750 by 100 millimeters.

Although the original vision was to use TuFF short-fiber sheet materials, because these were not available at the onset, RAPM proceeded with surrogate materials. This is actually beneficial for the composites industry because the surrogates span materials that are more reflective of what is being used and developed outside of this project: automotive organosheets and aerospace-qualified prepregs, experimental epoxies, semi-crystalline thermoplastics and chopped prepreg compounds. Thus, the results and findings relate to all types of composites manufacturers, not just to those in defense.

Track 1: Resin infusion/RTM manufacturing

Manufacturing development trials in this track started with automotive-type materials and processes. Parts were made by SGL Composites using high-pressure resin transfer molding (HP-RTM, 300 bar) and C T50 standard modulus, 50K carbon fiber noncrimp fabrics (SGL Carbon in Wackersdorf, Germany) in three part configurations: RI-RAPM-009, RI-RAPM-002, RI-RAPM-003 (Fig. 1). These were used to identify preform parameters necessary for high-quality finished parts. Gap infusion (compression RTM, or C-RTM) was also trialed for RI-RAPM-003 by Boeing St. Louis using its PtFS system.

Computational flow modeling was used to better understand how to infuse these parts, analyzing process behavior to optimize materials and process parameters and to evaluate injection scenarios.

Tooling approaches were evaluated for how and when to apply tension to different types of preform geometries in order to minimize fiber distortion. These design changes were validated for a modified C-channel geometry, followed by computed tomography (CT) analyses. Lessons learned were applied in the subsequent C&T phase, moving to low-pressure RTM (LP-RTM) to reduce cost.

Within these pathfinder part trials, delaminations were found in several of the deep-draw radii. Tsotsis believes these were caused by a combination of insufficient initial cure of the resin in the tool — because SGL’s steam heating system restricted in-tool temperatures to 130°C — and thermal/mechanical out-of-plane stresses during part removal. “Because the resin strength had not yet been sufficiently developed, these anomalies likely could have been eliminated with full cure on the tool, he suggests. “SGL could not meet both time on tool and aerospace properties until oil heating (versus steam only) was added to the tool, enabling cure above 130°C,” notes Hahn. This was added after the manufacturing development trials.

Fig. 3. Resin-infused challenge part

The RI-RAPM-004 deep-draw challenge part was made using low-pressure preforming and RTM, which permitted cost-effective Raku-Tool tools and hand-clamping mechanisms for preforming (top left) and aluminum tools for curing (top right). Multiple preforms were used to create the deep-draw geometry without wrinkles.

Deep-draw challenge part

Results from the manufacturing development trials were then used to develop challenge and transition trials. Modeling was also completed for the RI-RAPM-004 deep-draw challenge part (Fig. 3), which features two deep draws: a 5-centimeter rectangular region and a 10-centimeter region that transitions from rectangular to a V-shape. Inspired by a production pan assembly, its complex geometry ensured a non-uniform resin flow path. Huntsman (Basel, Switzerland) performed the flow modeling with PAM RTM software (ESI Group, Paris, France) for an LP-RTM process using FAF2 two-part epoxy (Huntsman, The Woodlands, Tex., U.S.) and SGL Carbon NCF 150-grams per square meter biaxial and 190-grams per square meter unidirectional (UD) reinforcements.

“We are publishing lessons learned, enabling more informed trade studies ... and establishing an open basis for industry discussion.”

RI-RAPM-004 comprises one preform for the skin, one for each of the deep-draw sections, plus two build-up areas (Fig. 3). Different layups were used for these preform elements to meet designed panel thicknesses (see “Manufacturing the complex geometry parts of RAPM”).

"Low-pressure preforming and LP-RTM allowed the use of cost-effective tools (compared to steel): the preform tool, with hand-actuated clamps, was made with polyurethane-based Raku-Tool material (RAMPF Tooling Solutions, Grafenberg, Germany); the curing tool was made with 5083 aluminum.

Initial RI-RAPM-004 trials showed an unexpected anomaly in the flow near the exit that lifted the surface plies, causing fiber distortion. Reversing the inlet and outlet resolved the issue. After infusion and initial cure in a 130°C tool, parts were post-cured at 180°C for 60 minutes and then machined to net shape. Ten high-quality parts were delivered to Boeing for automated ultrasonic system (AUSS) C-scans.

The finished challenge parts showed full consolidation, excellent fiber alignment and good quality. The parts exhibited a glass transition temperature of 197°C and a fiber volume fraction (FVF) of 49.5%, typical for the NCF used. Part layup piece count was reduced by more than two-thirds versus the current prepreg process, and touch labor dropped by an estimated 90%. RAPM has also made the challenge part with aerospace-qualified resins and fabrics — to test the adaptability of the tools and processes it developed — and fabricated parts that passed production requirements for nondestructive testing (NDT).

Track 2: TS prepreg forming

Fig. 4. Spring-frame compression molding

Spring-tensioned prepreg charge prior to compression molding (top) and molded part (bottom) for beaded panel TS-RAPM-009.

Three manufacturing development thermoset (TS) prepreg parts were manufactured at Solvay’s Applications Center in Heanor, U.K., using spring-frame stamping and/or double diaphragm forming (DDF). All three parts were manufactured using epoxy prepregs based on Solvay resins including CYCOM 5320-1, CYCOM 970 and the CYCOM EP-2750 aerospace system. “CYCOM 5320-1 is our go-to for out-of-autoclave (OOA) parts, but it’s also used as a qualified system for the autoclave,” says Hahn. “CYCOM 970 is a solvent versus hot-melt prepreg option, and [CYCOM] EP-2750 is our system for press forming because it is optimized for the physics and kinetics of the process, which we showed produces the best parts.”

Spring-frame stamping and DDF are isothermal compression molding processes in which thermoset prepregs are cut, collated and consolidated into a 2D preform. The preform is then preheated, shuttled into matched metal tools and molded into shape in a conventional hydraulic platen press. The preform may be held in tension by a spring-frame (Fig. 4), which reduces wrinkling induced by material compressive zones during forming. Alternatively, DDF sandwiches the preform between two diaphragms, eliminating the need for mold cleaning and release. The preform is taped to one of the diaphragms, essentially holding it in tension, though not as directly or tailorable as with a spring-frame. In RAPM, spring type, locations and tensions were optimized for each part using simulation, as was the spring frame. For example, the beaded panel TS-RAPM-009 used a frame that can actuate up and down to tailor the forming of the charge in parallel with the press closing.

RAPM minimized part-on-tool time by removing dimensionally stable parts after a 15-30-minute initial cure and then batch post-curing to increase rate capability. Part families were also investigated using a single toolset — e.g., a C-channel with three varying flange angles along the length of a wing — to maximize cell use. Other goals guiding the RAPM TS approach included:

- Automated collation and forming to minimize hand labor

- Aerospace mechanical performance with 177°C cure

- Steel tooling capable of >1,000 parts per toolset.

Development to “wave” challenge part

Thermoset prepreg manufacturing development parts were formed, indexing one variable at a time, until sufficient part quality was reached. Variables such as press closing speed, closing position and closing pressure were assessed, with the aim of consolidating the material at the correct point in the rheology curve to create internal hydrostatic pressure, minimize resin bleed and prevent cure from advancing too far, to avoid crack induction. Once forming parameters were set, three to five parts were made to verify process repeatability and then tested for quality. The beaded panels showed porosity of <0.5% due to high consolidation pressures (20.7 bar). Repeatable, high-quality ribs were also produced.

Lessons learned were then applied to the corrugated “wave” challenge part, TS-RAPM-012, to demonstrate compression molding of thick (6.3-millimeter nominal thickness) UD laminates in shapes with tight-radius (12.7 millimeters) curvature. To meet requirements, the part used a quasi-isotropic layup of intermediate modulus (IM7; Hexcel; Stamford, Conn., U.S.) carbon fiber UD tape. Outer layers of style 108 glass fiber fabric and Solvay THORNEL T650 standard modulus carbon fiber in an 8-harness satin fabric protect the UD fibers and prevent galvanic corrosion on the side that mates to a metal part. Using Solvay CYCOM 5320-1 epoxy resin allowed shorter-length (≤ 30 minutes) isothermal cure cycles with a 2-hour freestanding post-cure at 177°C.

The wave challenge part was molded using Boeing’s PtFS work cell and P20 steel mold faces with integrated vacuum and resin seals. The tool cavity was thinner than nominal laminate thickness to account for variation in the resin content of the material, maintaining internal hydrostatic pressure for high-quality parts.

Three process parameters were tested, including cold forming (pre-shaping plies without heat), hot debulk pre-consolidation and preheating the preform. Cold forming was rejected as time-consuming and not helpful. For pre-consolidation, laminates were vacuum bagged to a plate with a woven fiberglass breather and debulked under full vacuum in a 116°C oven for 40 minutes. Though an automated infrared preheat is standard for industrial production, in these trials, preheat comprised placing the preform in the hot mold (179°C) and closing as much as possible without touching for 3 minutes. The part was then compression molded.

Trial 8 of the nine completed (#0-8) produced the highest quality part, mainly attributed to pre-consolidation. Samples taken from it met thickness (an issue with other parts) and laminate quality with a fiber volume of 59-63% and void content of 0-0.6%.

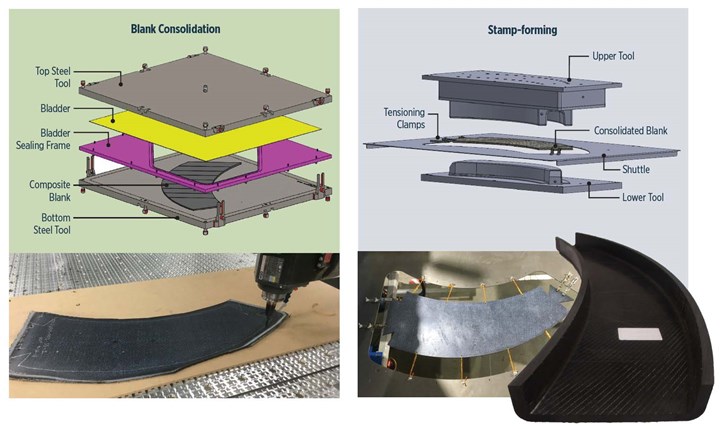

Track 3: Bladder-formed TP rib and C-channel

RAPM chose the TP-RAPM-002 rib from the manufacturing development trials to demonstrate single-step compression molding from raw material to finished complex part, and the TP-RAPM-003 curved channel for a two-step approach. Boeing St. Louis molded the -002 rib using an Accudyne Systems (Del., U.S.) press and consolidated blanks for the -003 C-channel using the PtFS equipment. In a second step, ATC Manufacturing stamped the C-channel blanks into parts.

For the -002 rib, RAPM used 12-inch-wide UD tape supplied by Solvay: 12K AS4D carbon fiber (Hexcel, Stamford, Conn., U.S.) reinforced polyetherketoneketone (PEKK). The -003 C-channel used fabric from Cramer Fabrics Inc. (Dover, N.H., U.S.): 3K AS4 (Hexcel) un-sized carbon fiber in a 2x2 twill, powder-coated with polyetheretherketone (PEEK); fiber areal weight is 250 grams/square meter; resin content is 42%.

Boeing St. Louis required novel tooling to create horizontal pressure on the rib’s vertical elements during consolidation in a hydraulic press that had only vertical actuation. Its solution was a thin aluminum bladder (a similar system was used to form TP-RAPM-003, Fig. 5). Pressurized with inert argon gas at high temperatures, the bladder expanded to apply even pressure to all part surfaces during consolidation.

Top and bottom tools were made from 410 stainless steel, which matched the in-plane CTE of the UD carbon fiber/PEKK laminate. During the press cycle, the upper tool with the aluminum bladder came down and slowly pressed the layup into the female cavity of the lower tool. The bladder was undersized 30% from the final part thickness to accommodate the bulk of the unconsolidated tape preform in this one-step process. This tool was mounted in a conventional press with electric heating cartridges, wired in 12 independently controlled zones — plus the six main zones of the press platen — to control the tool surface temperature in the rib’s flanges and web.

These forming trials produced composite parts with passable NDI results. However, the bladder tool design requires further development to improve forming the layup into the tight inner radii of the part and also to maintain uniform surface thickness.

Consolidating PEEK fabric blanks

For the TP-RAPM-003 curved C-channel, the powder-coated PEEK 2x2 twill fabric used had a relatively high bulk factor. Boeing St. Louis first consolidated the layup, which dropped from 32 to 24 plies along the length of the part, into a flat blank with a tapered cross-section, and then sent the blanks to ATC Manufacturing, which stamped the final part with vertical flanges.

As with the rib, Boeing used a forming bladder and steel top and bottom tools. The bladder was changed to AZ31 magnesium, which better resists rupture versus aluminum. The C-channel tool was designed to operate within the Surface Generation PtFS forming cell to enable more rapid heating and cooling versus the conventional press with cartridge heaters used for the rib.

The C-channel tooling approach was developed to increase flexibility for multiple parts. The layup was placed onto the bottom tool, which was heated to the material’s glass transition temperature (Tg) to maintain pliability without melting. A volume reducing frame that included a pressure-sealing gasket was placed on top of the bottom tool, leaving a cavity slightly larger than the part layup (Fig. 5). Heat and hydraulic pressure were applied from the top tool through the bladder to the layup. Once at forming temperature, argon gas was applied to the bladder, forcing it down into the frame cavity to apply pressure to the tapered blank. The tool temperature was then increased through the melt phase of the material while maintaining bladder pressure, which prevented material from flowing across the lower tool while in melt phase.

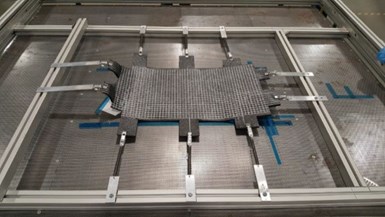

Fig. 5. Thermoplastic blanks to stamp-formed parts

Boeing consolidated the PEEK fabric blanks for the TP-RAPM-003 curved C-channel using an aluminum bladder and its PtFS system. Consolidated blanks were then sent to ATC Manufacturing, where they were stamped while held in a tensioning system to prevent wrinkles.

Preforming cycle time comprised 55 minutes for bladder and TP charge to reach process temperature and 30 minutes to cool below the PEEK crystallization temperature. Pressure ranged from 1.4 to 9.7 bar and was maintained manually from a high-pressure tank with a valve. With the recent incorporation of a pressclave system into the PtFS cell, autoclave-like control of vacuum and pressure (±3 psi) in the press mold cavity will be automated in the future.

TP stamp-forming

Consolidated blanks for the -003 C-channel were sent to ATC Manufacturing for stamp-forming, in which the blank is heated sufficiently above melt temperature to ensure polymer flow. It was then transferred to a rapidly closing press to form and cool the part quickly. The forming tool in the press is kept at constant temperature, enabling rapid cycle times by eliminating ramp-up and cool-down. The tool temperature must be between melt temperature and Tg to develop the required level of thermoplastic matrix crystallinity in a short time, yet ensure the part can be removed without deformation. A series of blanks with implanted thermocouples was used to validate the complete thermal cycle for stamp-forming the C-channel.

Forming simulations using Aniform software (Enschede, Netherlands) showed the highly drapable PEEK fabric blank still posed a risk of wrinkling in compression areas, namely the inner (smaller radius) flange. Thus, a tensioning system (Fig. 5) comprising shuttle plate and clips held the blank in tension as the matched metal tools closed to form it. Despite this, the flange face in compression still showed buckling as fiber was pushed inward at the inner radius. “All three RAPM tracks struggled to make this part,” Hahn contends. “Its geometry was extreme, and not so indicative of a real part, but more designed to push what we could achieve in formability.”

The manufacturing development trials led to challenge and transition parts that included multiple versions of the TP-RAPM-008 skin access panel, the TP-RAPM-013 rib with joggles on the flanges and a bladder study using three different geometries of the TP-RAPM-017 panel (Fig. 2). Boeing St. Louis produced all of these except for the TP-RAPM-013 rib, which ATC produced. “Even though this part was made with UD tape, which is typically more challenging to form versus fabric, we were able to form these parts very well,” says Trevor McCrae, R&D director for ATC Manufacturing. Overall, the TP forming trials showed that stamp-forming can produce complex geometries that might not be possible with conventional compression molding.

Learning to cut cost vs. aluminum

RAPM has demonstrated novel forming capability in all three tracks and amassed numerous lessons learned, ranging from how to position pad-ups to prevent slippage during compression molding to guidelines for part geometry to maximize quality and minimize tooling cost. “Understanding the effects of out-of-plane features, radius-to-thickness ratio and distance between geometric details becomes key as you move to small parts,” Hahn observes. “Standardizing features such as radii, curves and flange angles can help mitigate cost drivers, for example, reducing tooling costs, the number of forming trials during development and the need for multiple scans during NDI (nondestructive inspection) by enabling a standard AUSS shoe for a family of parts.”

Another cost driver RAPM highlighted was the time-consuming pre-consolidation step during TS prepreg compression molding. “Low-bulk and higher resin content prepregs widen the process window and increase repeatability for high-quality parts,” Hahn explains. “Solvay has developed a patent-pending ‘transformer film’ which can be applied to lower-impregnation prepregs before compression molding as a method of guaranteeing hydrostatic pressure in the mold cavity during consolidation.”

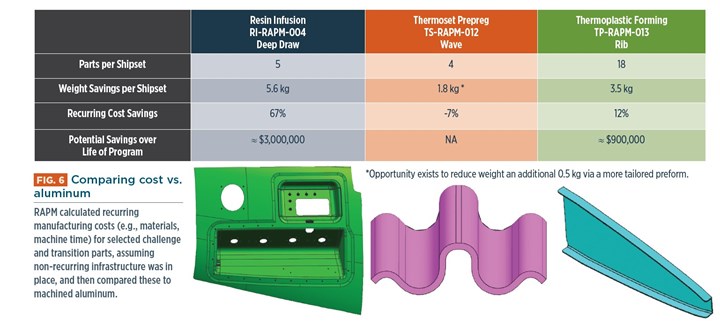

Although RAPM won’t officially end until fall 2020, followed by additional published results, findings so far for selected parts, which are based on real defense programs, show that composites can compete with machined aluminum (Fig. 6). Though the selected resin infusion and TP parts reduce recurring costs — e.g., materials, machine time, etc. calculated over total parts per family assuming non-recurring infrastructure is in place — the TS-RAPM-012 wave assembly actually shows a 7% increase vs. machined aluminum. However, it does achieve desired weight savings, and at a premium that is actually within the margin mandated by Hendrix: “No one is going to pay 2X for the weight savings composites offer; they must cost within 10 percent of aluminum.” However, he does concede, “There are still non-recurring time and cost issues to figure out, such as tooling and the development required to successfully form the shape.”

Fig. 6. Comparing cost vs. aluminum

RAPM calculated recurring manufacturing costs (e.g., materials, machine time) for selected challenge and transition parts, assuming non-recurring infrastructure was in place, and then compared these to machined aluminum.

Expanding options

Although resin infusion wins for large parts, says Hahn, TS and TP stamping look pretty good for small parts. “Initial tooling cost for resin infusion is hard to overcome unless the metal parts are very complex, requiring a lot of machining,” she explains.

“Thermoplastics look good for high volume, but a subcontractor for a given program might not be set up to do thermoplastics. However, thermoset stamping might be a very good option, even for low-volume replacement parts. Because defense applications are so wide-ranging, it is important to have more than one material and process in a trade discussion.” Hahn notes that RAPM has opened up new materials and proven aerospace materials can work in automotive-type processes. “We also brought in new manufacturers.”

Hendrix agrees that RAPM’s aerospace and automotive manufacturing exchange was beneficial. Further, he was impressed with Solvay’s and SGL’s ability to form complex shapes without fiber distortion or other defects. “What it takes to make aesthetic auto parts actually has benefits,” he concedes. “You can’t have wrinkles or bad surface finish; they have to be perfect. But it still took multiple trials and significant development for them to form the RAPM parts. I’m not sure defense programs will want to invest in this non-recurring engineering if they’re dealing with small quantities. The economics will be on a case-by-case basis, but tooling and development remain issues we need to address.” Hahn adds, “We are publishing lessons learned, enabling more informed trade studies with expanded options and establishing a reasonably open basis for industry discussion.” CW will continue this discussion with an update once RAPM wraps up later this year.

Related Content

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)