Autoclave

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

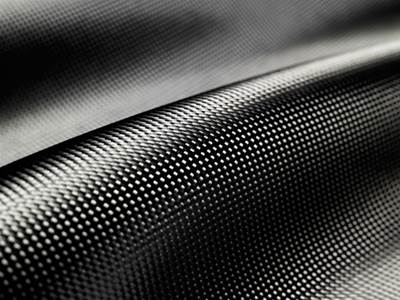

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreSafran Nacelles Morocco installs large autoclave, doubles cleanroom per development plan to increase production rates

Extension of 6,000 square meters dedicated to Gulfstream G700/G800 production, groundwork laid to digitalize processes and reduce environmental footprint.

Read MoreSaint-Gobain, Roctool join efforts to boost composite 3D textile preform parts manufacturing

3D automated knitted preform layup technology and heat and cooling technologies for additional curing efficiency open a new window of application opportunities for composite and thermoplastic parts.

Read MoreOut-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow

French Tier 1 aerospace supplier Daher develops out-of-autoclave materials and process technologies for application in next-gen structures for the Airbus Wing of Tomorrow program.

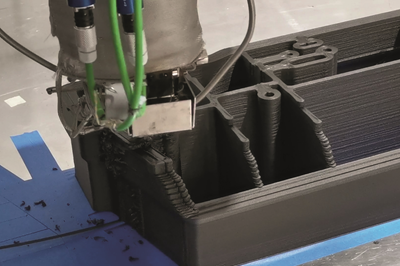

Read MoreCMS debuts hybrid LFAM/milling machine

The machining specialist has developed the first iteration of Kreator, a large-format, thermoplastic composite 3D printer and five-axis milling machine for tooling and jigs.

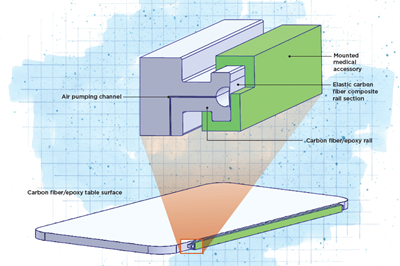

WatchDesign innovations improve efficiency of composite medical table

WIT-Composites' efforts to design a more effective all-composite surgical table led to development of complex components and an elastic carbon fiber material.

Read MoreNAWA Technologies develops U.S. subsidiary to extend VACNT application scope

NAWA America’s immediate focus is to bring NAWAStitch to mass market, a thin film containing trillions of VACNT arranged perpendicular to the carbon fiber layers to reinforce the weakest part of a composite.

Watch

.jpg;maxWidth=300;quality=90)