Autoclave

BMI and benzoxazine battle for future OOA aerocomposites

Offering weight, cost and process advantages, these “hot zone” resins are moving down the thermometer and into out-of-autoclave structural applications and autoclavable tooling now dominated by epoxies.

Read MoreBenzoxazine: An alternative to phenolic for interior fire safety?

As research into benzoxazine resin chemistry proceeds, this budding high-performance system has the potential to challenge phenolic resins in aircraft interiors.

Read MoreResin-infused MS-21 wings and wingbox

Moscow-based aeromanufacturer uses out-of-autoclave composites in attempt to leapfrog Airbus and Boeing with wider, lighter, more efficient single-aisle airliner.

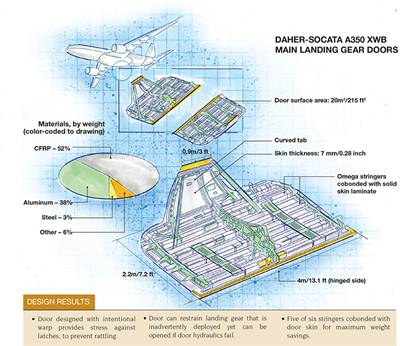

Read MoreMain landing gear doors designed for all contingencies

For the Airbus XWB airliner, they must meet strict structural, aerodynamic, emergency and aesthetic requirements.

Read MoreCarbon stairs make boarding a sailing yacht a breeze

GMT Composites (Bristol, R.I.) makes lightweight but strong — typically carbon fiber — yacht-boarding systems that are easily moved and stowed.

Read MoreOut-of-autoclave manufacturing: The green solution

Regular HPC columnist Dale Brosius calls attention to the environmental benefits of out-of-autoclave processing.

Read MoreRVB Infusion = Light RTM?

There is some difference of opinion as to whether parts infused under reusable vacuum bags (RVBs) are the equivalent of those produced by Light resin transfer molding (RTM). See why.

Read MoreRVB insider insights

Experts in reusable vacuum bag technology share insights into bags adapted for autoclave use.

Read MoreReusable vacuum membranes: Coming of age?

Durable custom elastomeric bags cut consumables cost and boost rate production.

Read MoreAutomotive CFRP: The shape of things to come

CAFE and CO2 emission standards will drive auto OEMs to fully examine the physics of fuel economy, but will that, at last, steer them toward extensive use of carbon fiber composites?

Read More