Autoclave

Ensuring cure: Viscoelastic feedback

Material State Management measures the cure state of composite structures, enabling not only shorter cure cycles but also the ability to optimize cure cycles.

Read MoreInside Manufacturing: An autoclave for the 787 center wing box

Development partners overcome cultural and geographical challenges to ensure cure of this massive composite structure for Boeing's Dreamliner.

Read MoreMarket Trends: The Composites Affordability Initiative, Part I

The Air Force Research Laboratory's Dr. John Russell outlines the U.S. Department of Defense Composites Affordability Initiative. Part I of a two-part series.

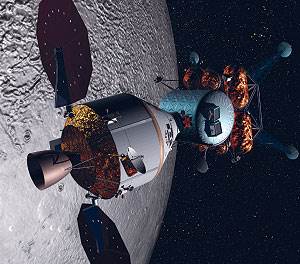

Read MoreOrion: Composite tanks' ticket to space?

Research, development, testing prove composites can contain cryogens.

Read MoreCOMPOSITES POLYCON 2006

ACMA's and ICPA's trade shows converge in America's middle, St. Louis.

Read MoreAdvanced materials for aircraft interiors

Applications aren't as demanding as airframe composites, but requirements are still exacting — passenger safety is key.

Read MoreFilament winding

Filament winding is a continuous fabrication method that can be highly automated and repeatable with relatively low material costs. A long, cylindrical tool called a mandrel is suspended horizontally between end supports, while the “head” – the fiber application instrument – moves back and forth along the length of a

Read MoreCarbon car hood: Class A and cost-effective

Resin film infusion, electroformed nickel tooling meet Aston Martin quality and cost targets.

Read MoreComposites in Sailboats: Room to Grow

Composites continue to play a key role in the sailboat industry, having become almost universal at all levels of sailboat custom and production manufacturing. Composite sailboat building started with the famous Bounty design in the 1950s, and in much of the industry, basic manufacturing practice has changed little

Read MoreComposites in Boat Accessories and Hardware

All the stuff that goes inside, stem to stern.

Read More