Consumer

An impec-able bike frame: Handmade by machine

Long on technology firsts, this optimized, automated manufacturing process produces nothing short of the “perfect” bike frame.

Read MoreNext-generation braiding for next-gen bike

When Grenchen, Switzerland-based Bicycle Manufacturing Co. (BMC) decided to braid the tubes for its impec racing bike frame, the use of carbon fiber and the complex tube designs and shapes prompted the use of radial braiding technology from August Herzog Maschinenfabrik GmbH & Co. KG (Oldenburg, Germany)

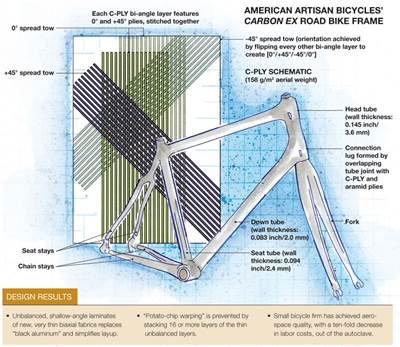

Read MoreBi-angle fabrics find first commercial application

Bicycle manufacturer sees dramatic productivity gains using unbalanced fabrics conceived at Stanford University and manufactured by Chomarat.

Read MoreComposites as costume: Manga masterpieces

Sophisticated design meets composite materials and manufacturing in cosplay application.

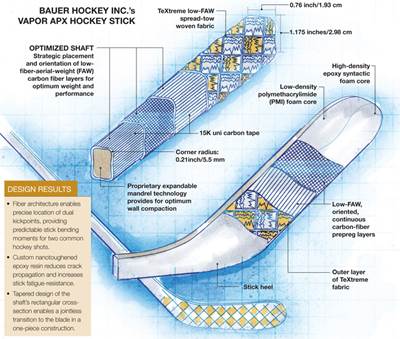

Read MoreAdvanced hockey stick design delivers optimal performance

Carbon fiber composites and an innovative new resin system play key roles in the design of an elite-level stick.

Read MoreCarbon fiber market: Gathering momentum

All signs point to increasing demand from many market sectors. Will capacity keep pace?

Read MoreBarrier coats in pool production

Barrier coats protect fiberglass swimming pools from invasive water-treatment chemicals.

Read MoreAutomating swimming pool production

Small producer ramps up productivity with "entry level" robotics.

Read MoreDesigning bicycling’s lightest pro racing frame

Cervélo’s Vroomen White Design group combines analysis and manufacturing acumen to create a 675g/1.5 lb composite frame.

Read MoreSpread-tow fabrics reduce waveboard weight

Fanatic (Molln, Austria) recently introduced a new version of its windsurfing waveboard, called FreeWave TeXtreme, made with TeXtreme spread carbon tow fabric from Oxeon AB (Boras, Sweden).

Read More

.jpg;maxWidth=300;quality=90)