Custom Content

Filament winding software maximizes accurate fiber placement

CAMX 2024: Roth Composite Machinery is exhibiting its µRoWin winding software, amongst other product options like its automation concept for reliable fiber changing.

Read MoreMitigating Carbon Fiber Emissions for Fabricators

Thermal or catalytic oxidation devices are capable of achieving over 99% destruction of the emissions from carbon fiber manufacturing. Recent developments in these technologies have improved efficiency, effectiveness, process uptime, and reduced carbon footprint.

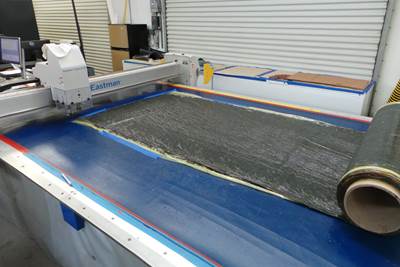

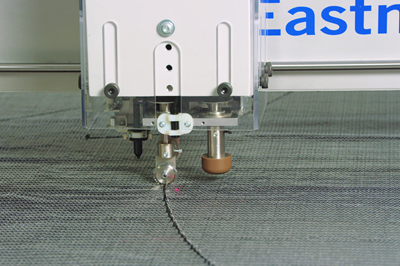

WatchFiberglass Cutting Operation at Hubbell’s Lenoir City Plant Moves to Automation

Automating fabric cutting operations saves Hubbell Lenoir City money and can produce composite products faster at less cost to support infrastructure expansion.

Read MoreTop 10 Considerations When Buying a CNC Machine for Composites

For a CNC machine to continue to meet or exceed a company’s needs, it must be built and spec’d with these needs in mind.

Read MoreDifficult Materials Make Automated Fabric Cutting More Indispensable than Ever

With lingering supply chain shortages, difficult-to-cut materials like Kevlar and many others demand a more accurate and efficient cutting process. Automated cutting is the answer.

WatchPrecision Cutting Enables High Speed Composites Molding Process

Automatic cutting of proprietary composite materials is critical for high speed molding of military-grade pressurized camera enclosures.

Read MoreHow Digital Cutting Technology Reduces Costs and Improves Flexibility

Automated cutting of composites reinforcement and other technical textiles is faster, more accurate and can result in dramatic reductions in material waste and labor. Having the right software is the key to getting the best results.

WatchComposite Bonding & Repair Benefits and Solutions

Film and paste adhesives, wet peel-ply and potting compounds enable the aviation industry to utilize advanced materials that contribute to lightweighting, more efficient designs, and improved sustainability.

WatchAutomated Cutting of Composites Reinforcement Saves Time and Material, Improves Quality

Automated cutting of reinforcement materials is fast, accurate and reliable. It reduces labor costs and material waste and can substantially boost throughput.

WatchRevisiting the Fundamentals of Light Resin Transfer Molding (LRTM)

Like other closed molding composites processes, Light Resin Transfer Molding (LRTM) offers reduced waste and emissions, efficient materials use and a consistent and repeatable process. But LRTM requires less costly tooling and can still provide excellent cosmetics on both sides of a part in an efficient manufacturing process.

Read More