Design/Simulation

Very Light Jets Creating A Demand For Composites

"Baby" jets are causing an aviation buzz but will the market exist?

Read MoreRTM showcase: One-Piece Rudder

A transatlantic design team uses concurrent engineering to integrate rudder spars, ribs and skins in a single RTM cycle.

Read MoreFree-form surfacing optimizes free-style kayak

The 6-ft/1.8m-long Project 54cx kayak, made using aramid and carbon fabric-reinforced composites, weighs only 19 lb/8.6 kg.

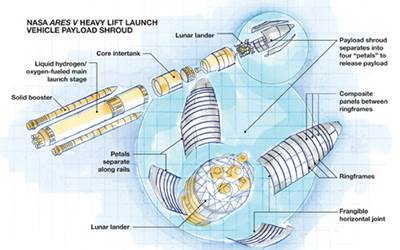

Read MoreOptimizing the Ares V payload shroud

Sizing software allows rapid analysis of candidate composite architecture for highly loaded and weight-sensitive launch vehicle component.

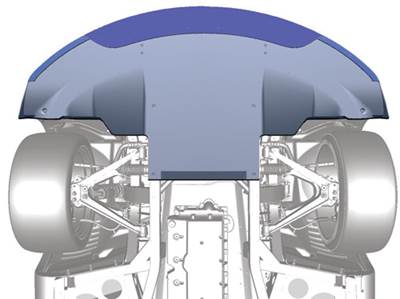

Read MoreSimulation simplifies fabrication of all-composite crew module

Specialized simulation software shortens development cycle on first all-composite crew module demonstrator for NASA space program.

Read MoreDirect manufacturing of military aircraft parts

Laser sintering process shortens lead time, simplifies production of complex, high-performance parts.

Read MoreTeam-built bus body bests all

OEM meets tight development schedule on superlight multipart molded shell to offset propulsion system weight in fuel cell-powered transit bus.

Read MoreChallenge of engineering retrofit blades

Myriad interrelated design factors are considered in new blades for turbines originally built for high-wind regimes.

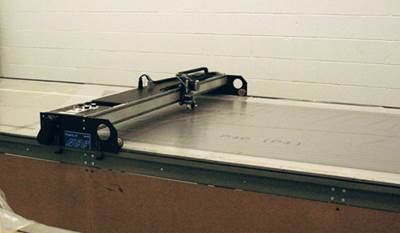

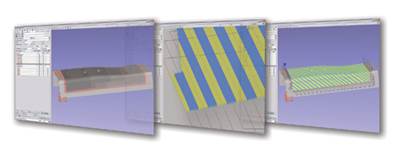

Read MoreAFP/ATL design-to-manufacture: Bridging the gap

Managing production of a structure made via fiber or tape placement often requires software-aided manipulation of the subtle differences between that which is designed and that which can be manufactured.

Read MoreComposite wing key to high-speed stability

First mass-produced CFRP wing helps supercar achieve downforce and lateral acceleration values superior to many GT racing cars.

Read More

.jpg;maxWidth=300;quality=90)