Simulation simplifies fabrication of all-composite crew module

Specialized simulation software shortens development cycle on first all-composite crew module demonstrator for NASA space program.

Several years ago, NASA’s Engineering and Safety Center (NESC), housed at the U.S. space agency’s Langley Research Center (Hampton, Va.) was charged by then agency administrator Mike Griffin with determining the most suitable composite materials for use in construction of future NASA spacecraft, such as the upcoming Constellation mission hardware that will once again carry U.S. astronauts to the Moon (see “Learn More”).

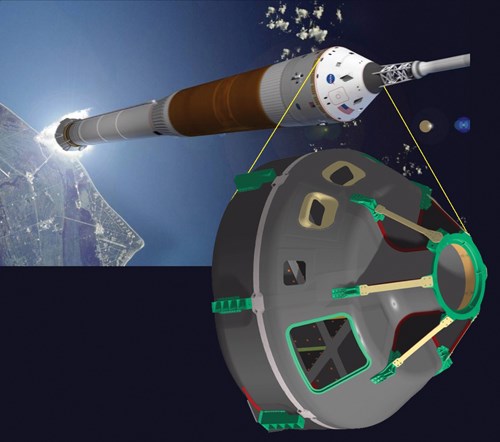

NESC selected the Constellation mission’s Orion crew module to demonstrate how composites could affect overall payload capacity and mission economics. Orion, as built by Lockheed Martin, is 40 percent composites by mass, but its pressure module is aluminum. NESC’s parallel demonstration crew module, however, is an all-composite structure. Mike Kirsch, NESC’s project manager for the composite crew module, or CCM, says that VISTAGY Inc.’s (Waltham, Mass.) trademarked FiberSIM composites engineering software was a key element in the effort.

The CCM team, which included not only nine of the 10 NASA sites around the country but also a number of major commercial aerospace firms, considered nearly a dozen concepts before deciding to make the CCM pressure structure a stiffened honeycomb sandwich, with carbon fiber/epoxy skins and aluminum honeycomb core. Solid, uncored laminate was placed in key locations.

The CCM vehicle is composed of an upper and a lower pressure shell that are spliced together with a double lap shear joint. However, Kirsch notes that a one-piece part was feasible, using multipart extractable tooling, but was not attempted due to schedule and budget constraints. Gussets, panels and various metallic fittings were used to strengthen the shell to distribute point loads. The lower shell incorporates a structural “backbone” of composite I-beams (honeycomb-cored carbon/epoxy) to carry pressure and inertial loads. Pro/ENGINEER Wildfire CAD/CAM/CAE 3-D design software from PTC - Parametric Technology Corp. (Parametric Technology Corp., Needham, Mass.) was used to produce the manufacturing drawings for the CCM.

“It’s a big step to go from Pro/ENGINEER Wildfire to the manufacturing floor and then layup,” says Kirsch. The FiberSIM software was able to define the individual ply segments, referred to as “flags,” and calculate how large and what shape they could be to conform to the tooling and eliminate wrinkles. FiberSIM calculated the shapes for the flat patterns and then exported that data to the NC flat-cutting machine, displaying splices, darts, boundaries, local coordinates, warp angles and more, to assist engineers in layup. The software generated the data to drive accurate laser projections of the flag boundaries and core trim areas onto the tool, as well as inspection grids, with equipment provided by Virtek Vision International Inc. (Waterloo, Ontario, Canada).

“Without the projection feature, determining the location of the flags would have been a painfully slow process and quality would have degraded,” says Ian Fernandez, the lower structure lead, based at NASA Ames Research Center in Moffett Field, Calif.

The recently completed CCM (see "ATK delivers composite crew module to NASA for Orion," under "Editor's Picks," at right) is 10 to 15 percent lighter than its aluminum counterpart, a reduction that has the potential to significantly reduce future launch costs. Static testing of the CCM will assess its performance under simulated mission loads. Kirsch is convinced that composite spacecraft will play a major role in NASA’s future missions, where weight is critical.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More