Direct manufacturing of military aircraft parts

Laser sintering process shortens lead time, simplifies production of complex, high-performance parts.

Design Results

- Production of complex aerospace parts directly from CAD data, on short lead time, without tooling or layup.

- Tremendous design flexibility, part-count reduction and customization on the piece-part level.

- High-performance, high-temperature polymers enable the process by providing higher properties than commodity polymers associated with rapid prototyping.

It’s as if the Star Trek replicators had been brought to life: Direct manufacture of complex parts from CAD data, without tools and with little lead time. Based on rapid prototyping (RP) technology and known, commercially, as direct digital manufacturing, rapid manufacturing, e-manufacturing and additive manufacturing, CAD-to-part technologies are making inroads in many industries, bringing with them great potential for design customization and part count reduction on a piece-part level.

As part of a government-funded effort, including a Small Business Innovation Research (SBIR) contract, composite aerospace components supplier Royal Plastic Mfg. Inc. (Minden, Neb.), is taking advantage of these possibilities in small components for military aircraft programs, working in conjunction with strategic partners The Boeing Co. (Seattle, Wash.), the Office of Naval Research (ONR), the Air Force Research Laboratory (AFRL), Northrop Grumman (El Segundo, Calif.) and RP machinery supplier Electro Optical Systems GmbH (EOS, Munich, Germany).

“The potential for direct additive manufacture in aerospace is significant, for fast CAD-to-part manufacture with a lot of design flexibility,” says Tim O’Dey, Royal Plastic’s engineering manager. But that doesn’t mean it will be easy. “There are also a lot of challenges involved to make robust parts that meet the performance criteria and the rigors of qualification for aerospace — the rapid prototyping concept needs refinement.”

Rapid prototyping/rapid manufacturing technology overview

The concept of rapid prototyping began more than 20 years ago in 1986, when the first stereolithography (SLA) process was patented. With it, part designers could bypass prototype tooling and create a low-cost part directly from a CAD file in a matter of minutes or hours, depending on the part’s complexity, by a method generally known as additive fabrication. As the name implies, the process builds a three-dimensional model from a series of two-dimensional, horizontal layers using materials (usually, a polymer or metal in liquid or powder form) that are fused together by an energy source. SLA was later joined by other RP methods, including fused deposition modeling (FDM), laser sintering (LS), 3D printing, direct metal deposition, and electron beam melting (EBM). Initially, the RP materials formed parts with properties sufficient only to evaluate form and fit. Later, sturdier materials permitted some testing, such as wind-tunnel evaluations. Over the past decade, however, further material upgrades prompted engineers to envision RP as a part production option. In commercial aerospace, LS using neat polyamide (nylon) has emerged as the most common method because it has been adapted to the widest range of engineering thermoplastic materials and generally produces higher part quality, says O’Dey. Although the parts are not structural and tend to be small, such as duct components, clips and brackets, they still must meet defined performance criteria.In the military aerospace market, the method has attracted interest because of its potential for part cost savings and the ability to create new copies of legacy parts from either the original CAD information or reverse engineering data, says Boeing engineer David Dietrich: “The ability to quickly fabricate high-temperature polymers allows for the expansion of part family lists in aging aircraft and spares markets. These emerging markets require flexible manufacturing processes that correlate with flexible supply chains, and high-temperature laser sintering offers this capability.”

But military platforms also require high-temperature performance. “Higher speeds and higher engine performance drive higher material specs in a lot of areas on the aircraft,” says O’Dey. ”Commodity nylon just can’t deliver.”

Matching process and polymer

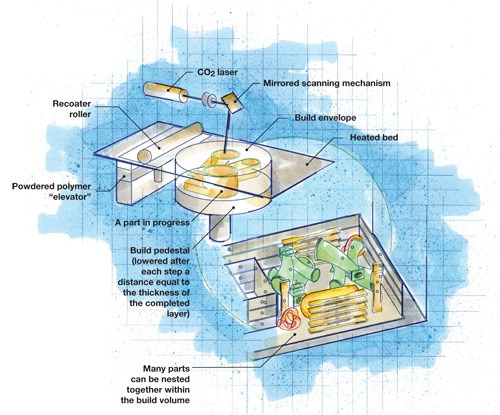

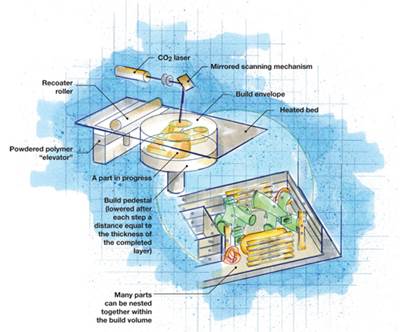

For that reason, Royal Plastic’s program partners specified high-temperature laser sintering hardware, which is now capable of processing high-temperature engineering polymers. The program employs EOS’s P730 HT laser sintering machine, which has a part-build envelope of 700 mm x 380 mm x 580 mm (27.6 x 15.0 x 22.8 inches). Like other LS systems, it consists of an enclosed fabrication chamber with a flat, heated bed, where a powdered thermoplastic polymer, elevated to the bed surface in a piston-operated chamber, is dispersed by a roller in a thin layer over a “build pedestal” on which one or multiple parts (depending on part size) will be built. A high-power CO2 laser, refracted through a scanner, heats and fuses the powder in a 0.15-mm/0.006-inch thick layer, in a CNC-controlled pattern defined by the part design data. The build pedestal is then lowered a distance equal to the thickness of the completed layer, and the recoater distributes more powder over the bed for the next layer. Unsintered powder gathers around and supports the part(s) as it (they) build up.The next step was to find the right polymer, says O’Dey. Candidate materials had to have at least similar properties to injection-molded neat plastics, with ultimate tensile strength of 15,000 psi and an elongation value of at least 4 percent, ultimate compressive strength of 15,000 psi, and a target density of at least 0.7 g/cc. It also had to have resistance to common aerospace fluids and a wide range of operational service temperatures, specifically those generated near engines where temperatures could reach upwards of 232°C/450°F. Those specs eliminated most rapid prototyping materials, leaving high-performance polyamide (PA), polyphenylene sulfide (PPS) and polyetheretherketone (PEEK) as candidates.

Next, says O’Dey, came the issue of how the materials interacted with the process. Only crystalline or semi-crystalline polymers were suitable for the sintering process, he explains, because they transition from solid to liquid within a narrow and well-defined temperature band, which helps maintain a part’s dimensional stability: “Laser sintering polymeric materials involves heating a chamber to just below the melt point of the material, then adding incremental laser power, providing just enough energy to melt the powder,” he explains. “Amorphous polymers have a ‘semi-solid’ transition with a phase change that occurs over a fairly wide temperature range, which adversely affects the process and the part.” Also critical is the viscosity of the polymer melt. Suppliers’ polymers tend to differ in melt flow rates. Low rates improve part dimensional accuracy and part surface quality, but high rates increase both part density and the crosslinking that occurs between horizontal layers, he explains, adding that polymers also degrade as they are subjected to multiple heat cycles through recycling. This degradation can be quantified through melt flow indexing. “Our work with these different available materials has involved testing and screening of these properties and their effects on the end product.”

Polymer particle size distribution was another key parameter. “It has a definite impact on processability and, ultimately, on whether a material is compatible with the process,” says O’Dey. If polymer particles less than 10 µm are present, they tend to melt too quickly, causing uneven melting that can destabilize the powder bed. Particles larger than 120 µm interfere with the smooth flow of powder across the powder bed. “We’ve tested different particle size ranges along with different recoat thicknesses to try to determine the optimal combination of these parameters.” O’Dey’s team used differential scanning calorimetry (DSC) to determine the polymer phase transitions and melt flow characteristics, as well as detailed particle size distribution comparisons, to help fine-tune the material/process design.

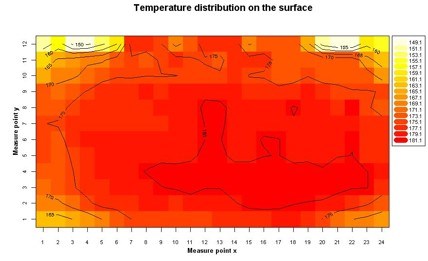

As one might expect, the hardware setup was critical. Ideally, heat distribution across the powder bed would be absolutely isothermal — the same everywhere — for best part quality. However, in Royal Plastic’s early work, heat distribution across the powder bed varied, based on the locations and directional heat characteristics of the quartz rod heaters employed in the sintering machine. Further, the heat distribution pattern tends to change as parts are built up, because the parts act as heat sinks, affecting the thermal gradient. But O’Dey believes that this variation can be minimized by using a greater number of quartz heating elements, using a staged heating sequence and/or making changes to the machine itself, as the program moves into serial production.

Design of experiments

Royal Plastic is validating the process for part manufacture by conducting design of experiments (DOE) or information-gathering experiments where all of the many variables are identified then manipulated to determine their importance. “It’s a big optimization problem,” says O’Dey, who reports that the high-temperature LS process performs well using polyamide as a baseline. Work is now underway with a PEEK resin by Advanced Laser Materials LLC (Temple, Texas), and trials also have been run with high-temperature PA and PPS.

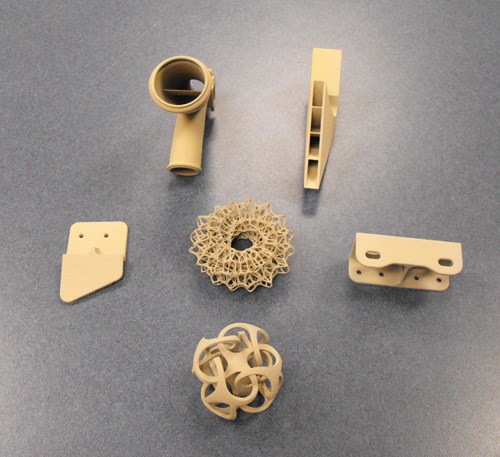

To maximize process efficiency, numerous parts are nested together as tightly as possible within the build area. Nesting minimizes the accumulation of excess unsintered powder, and reduces waste, and much of the powder can be recycled and reused. The parts are then tested and analyzed to determine whether or not they meet performance criteria. O’Dey reports that PEEK is the best of the three high-performance engineering plastics investigated thus far, and has good sinterability and thermal stability, with moderate mechanical properties compared to injection-molded plastics. By contrast, PA tends to absorb too much moisture while the PPS is difficult to sinter.

In terms of neat PEEK material performance, the result, thus far, has been mixed. Compressive properties are good — similar to injection-molded materials in some cases — but tensile performance remains elusive. The reason, explains O’Dey, is that because the parts are built up from planar layers, z-directional properties are compromised. To improve interlayer adhesion, Royal Plastic is investigating machine changes. “Varying the machine’s processing parameters is the key to successfully processing the material,” he says, noting that laser power, laser speed and laser beam offset affect the watt density delivered to the part bed. “All of these are under consideration to more effectively crosslink the layers and improve z-directional properties.”

Composites to the rescue?

Significantly, the company also is trialing parts made with polymers to which nanoscale carbon reinforcements have been added to improve tensile properties. The resulting composite parts, because of the carbon content, would offer conductive properties, a key advantage for parts in certain applications related to lightning strike. Thus far, however, the carbon additive increases tensile performance but adversely affects elongation and impact performance, which is important for small parts like wire clips, for example.Concludes O’Dey, “This is currently a very touchy process — you get a relatively low-cost production method for low-volume, complex-geometry parts and a lot of design flexibility. But, available materials are currently limited and mechanical properties need improvement, particularly in the z-direction. There’s a lot more to be done, but there’s a market for the process and it shows promise.”

Cue Captain Kirk.

Related Content

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreRead Next

The rise of rapid manufacturing

An outgrowth of rapid prototyping, tool-free additive fabrication technologies have the potential to form small, limited-run composite parts directly from CAD data.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More