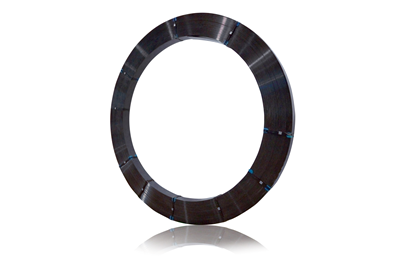

Pressure Vessels

Hexcel partners with Metyx for high-performance carbon fiber pultrusion technology

Combined expertise within the composites industry will contribute to the manufacture of profiles made from polyurethane resin and UD carbon fiber for the wind energy market.

Read MoreThe outlook for carbon fiber supply and demand

The picture painted at Carbon Fiber 2021 concerning the current supply and demand for carbon fiber indicates an in-flux, rapidly changing environment across a majority of end markets.

Read MoreRe-Wind Network releases repurposed blade design catalog

Re:Wind Design fall catalog presents designs and details of structures and products developed from EOL wind blades, as well as the research team’s services for those interested in repurposing their own.

Read MoreLM Wind Power reports it will produce zero waste blades by 2030

Blade manufacturing waste prevention and recycling becomes the GE Renewable Energy business’ primary focus as it seeks to reduce its carbon footprint.

Read MoreJoule Challenge project launch uses composites for next-generation wind turbine development

Two-part project is to produce a 20-MW demonstration turbine, capitalizing on the U.K.’s large composite component expertise and support the ambition for lower cost manufacturing.

Read MoreNexam Chemical, the NCC develop solution for manufacturing high-temperature composites

Nexam Chemical’s Neximid high-temperature resin system can operate at temperatures up to 400°C, expanding the boundaries of composites into more demanding applications that weren’t previously possible.

WatchU.K.’s first wind turbine blade recycling pilot project secures funding

The £2 million, three-year project aims to ensure global wind and composites sustainability via commercialization of a novel method of separating glass fiber reinforcements from its resin system.

Read MoreACS-A to develop composite prototypes, processes for MoorPower wave energy project

The two-year, Australia-based demonstrator project aims to use wave energy conversion technology to decarbonize offshore aquaculture operations.

WatchAimplas, industry partners set sights on chemical recycling of composites

The EROS project, with the participation of Aimplas and the Institute of Ceramic Technology (ITC) is working to develop new recycling process to recover and repurpose composite materials from wind and aeronautic industries.

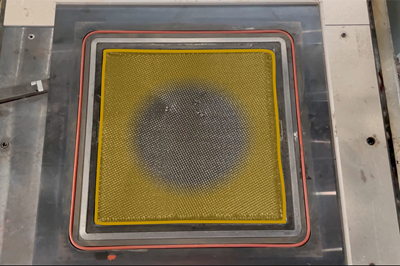

Read MoreIn-situ composites sensors for increased production rates, smart processes and life cycle monitoring

Com&Sens FBG sensors are embedded into pressure vessels, rudders and bridges, with new edge and surface connection technology, aimed at cost-effective serial production and monitoring of composite structures.

Watch

.jpg;maxWidth=300;quality=90)