Epoxies

CompoTech launches standard range for carbon finer epoxy beams

Produced via AFP and precision press molded results in a high-strength carbon epoxy composite beam with 10-15% higher stiffness in the axial direction.

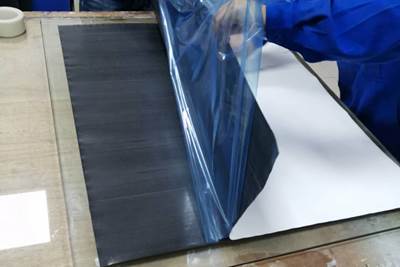

Read MoreSino Polymer develops high-performance epoxy resin systems for prepreg applications

The one-component carbon fiber prepreg can be cured at 150ºC for 10 minutes, is suitable for structural parts requiring Tg within 120-140ºC and can be stored for up to 18 months at -18ºC

Read MoreComposites complete IYRS heavy lift quadcopter demonstrator concept

Boasting a prepreg carbon fiber airframe, the HLAP concept became a platform for a variety of composite fabrication techniques.

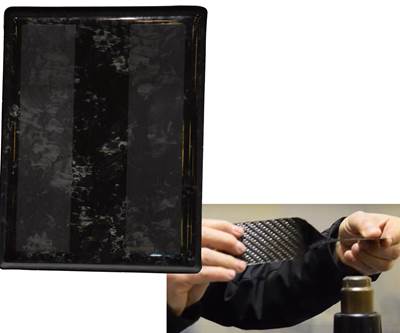

Read MoreCAMX 2020 exhibit preview: DH Sutherland

DH Sutherland is introducing technologies for chemical application and the manufacture of protective armor.

Read MoreThe industrialization of thermoplastic epoxy

Fast-processing composites that are strong yet tough, thermoformable, reformable, recyclable and even FST-compliant save cost in aircraft and rail equipment.

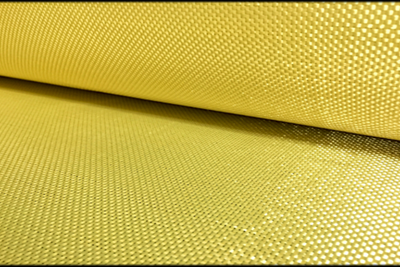

Read MoreSky Advanced Materials fabrics win DNV-GL type approval

Certification for Hungary-based Sky Advanced Materials covers use of fabrics made with Zoltek PX35 50k tow carbon fiber combined with epoxy or vinyl ester.

Read MoreSino Polymer develops high-performance epoxy resin prepreg

Used in railway applications, the carbon fiber prepreg can be cured at 150℃ for 10 minutes, and is suitable for structural parts requiring Tg within 120-140℃.

Read MoreAimplas-led project develops thermoplastic prototypes

The RECONTRANS project adapts Arkema’s Elium thermoplastic resin for car, truck and rail applications.

Read MoreHigh-rate, automated aerospace RTM line delivers next-gen spoilers

At Spirit AeroSystem’s Prestwick facility in Scotland, a glimpse of the future of aerocomposites manufacturing in a resin transfer molding line for A320 spoilers.

Read MoreRS Electric Boats selects Norco for composites fabrication

Comprised of bio-based infused epoxy resin, recycled PET core and basalt and flax fibers, the Pulse58 drives a different approach to boating.

Read More