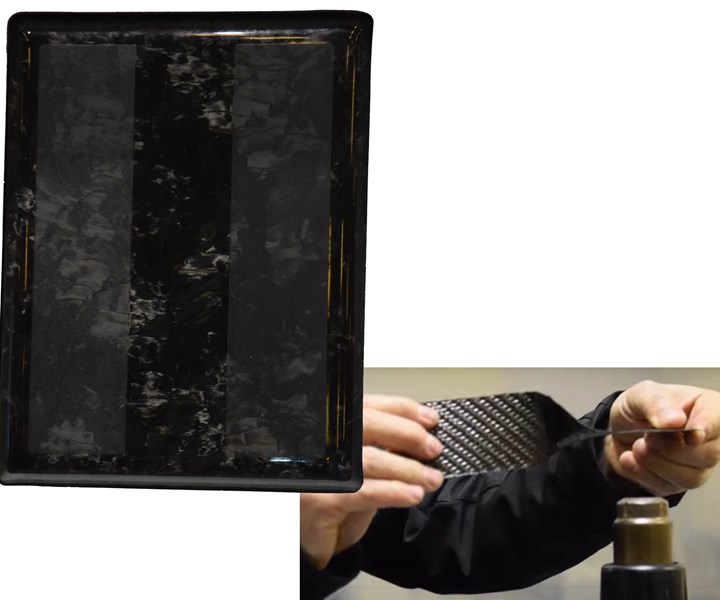

Fast-molding and reformable epoxy

RocTool molded Cecence K_Chips thermoplastic epoxy material in 2 minutes, 40 seconds with excellent matte and gloss surface finish (left). Having the high-strength and bondability of epoxy, K_Series materials are also thermoplastic and reformable at 180-200°C without chemical reaction or exotherm (right). Source | Cecence

Cecence (Salisbury, U.K.) was established in 2014 by three founders with decades of composites experience. Director Mike Orange had a long history in carbon fiber-reinforced polymer (CFRP) rigging and masts for yachts. Head of innovation Humphrey Bunyan was previously head of innovation at Future Fibres (Valencia, Spain). “They [Future Fibres] were making all-composite rigging for America’s Cup and other racing vessels, as well as CFRP tethers to hold the wheels onto Formula 1 cars,” says Orange (see “Yachtbuilding composites: Rigged for success”). “We understood the advantages of lightweight but were engaging with other sectors who didn’t have our experience and struggled with cost, scaling up manufacturing and meeting fire regulations.”

Thus, Cecence (pronounced “see-sense, as in common sense with carbon fiber composites) was founded to focus on fire resistance, industrialized manufacturing and sustainability. This resulted in developments such as a compression molded carbon fiber/bioresin composite seatback for passenger aircraft that weighed only 7.5 kilograms, reduced seat thickness to less than 20 millimeters and increased passenger space and comfort, while meeting all fire, smoke and toxicity (FST) requirements.

“In a previous project, Cecence had developed a hot press manufacturing method which shortened cycle time from 2.5 hours to 7 minutes for an economy class seatback using snap-cure phenolics developed with U.K. prepregger FTI (Somerset),” says Orange. For this latest seatback described above, which it developed with Design Q (Redditch, U.K.), Cecence expanded its FST portfolio by using a polyfuryl alcohol (PFA) resin prepreg developed by SHD Composites (Sleaford, U.K.). PFA is a thermoset polymer derived from biomass that performs like a phenolic with excellent surface processing and sustainability (see “Withstanding fire without the weight”). “We worked with SHD Composites and pushed their chemistry for a faster cure,” says Orange. “That is what we do: take materials, processes and designs and further develop them so that composite products can be manufactured at scale in a way that is commercially viable yet sustainable.”

Fig. 1. Family of K_Series products

From left to right, K_Rod bonded into a steel socket, cut carbon fiber/thermoplastic epoxy tows for K_chip molding compounds and compression-molded, fabric-reinforced K_plate. Source | Cecence

Manufacturing speed and sustainability were key factors when Cecence encountered a thermoplastic epoxy resin system several years ago. “This thermoplastic with epoxy components at the end of its polymer chains was being used by a fabric company that didn’t realize its potential in composites,” Orange explains.

“We understood immediately the advantages of a low-viscosity thermoplastic that could impregnate fibers really well while enabling a thermoformable epoxy,” says Humphrey Bunyan. Cecence developed a prepreg based on this thermoplastic epoxy technology, and then a family of products under the K_Series brand: coilable K_Rod, 0.25- to 1.98-millimeter-thick semi-preg K_Plate, and K_Chip molding compound (Fig. 1). “We have been able to press-mold components in under three minutes,” says Orange, “and have demonstrated an FR variant that meets FST requirements for aircraft interiors.” Cecence has also used the material to develop a composite overhead line equipment (COHLE) system for electric rail lines that reduces the number of support pylons/poles by half and overall installation and operation cost by £100,000 ($124,200) per kilometer.

Thermoformable epoxy

“With typical thermoplastics, you have a high-viscosity matrix polymer that is difficult to force into the fibers,” explains Bunyan. “Thus, it’s hard to get good impregnation of the tows or fabrics. But the K_Series thermoformable epoxy has very low viscosity — 80 centipoise at 100°C. This allows us to prepreg glass, carbon and natural fiber reinforcements with excellent resin-to-fiber distribution and typically 60% fiber content by weight. We can also use fibers with sizing for epoxy, which is typically not compatible with thermoplastics.” And yet, this system is a true thermoplastic, enabling reforming of finished parts at 180-200°C with no chemical reaction or exotherm.

“Like epoxy, it adheres well to the fiber, so there is no fiber separation from the matrix, even if you use higher pressures during molding,” notes Orange. This refers to an issue he has seen with short fiber-reinforced polyamide (PA) and polypropylene compounds. “We were working with a layer of PA melted onto a fabric via hot pressing to make a flat sheet. The matrix wasn’t sticking to the fibers, just surrounding them. So, when it was pressed into a part, you would get fiber pullout.”

K_Plate, which processes at 150-220°C, offers a service temperature of 100°C for short exposures and continued use at 90°C. Chopped unidirectional tow K_Chip compounds are pressed at 240°C. “The Tg [glass transition temperature] and onset of heat deformation for K_Series are lower than typical epoxies, but this is also what makes reforming and recycling feasible,” says Orange. K_Series processes are also fast. “Cecence worked with RocTool [Le Bourget du Lac, France] at JEC 2016 to demonstrate the fastest-forming thermoplastic they had seen,” he says, noting a cycle time of 2 minutes, 40 seconds for an automotive hood. “The dwell time was only 25 seconds before cool-down, using 8-9 bar of pressure above the vacuum membrane. They were also pleased with the finish of both matte and gloss surfaces [see opening image], noting our material provided the best finish of all those trialed.”

Also, the epoxy components in the K_Series products makes composite parts easy to paint and bond, without the special primers and preparation required for traditional thermoplastics. “You can secondary bond them using standard adhesives,” adds Bunyan. “You also get good interlaminar shear properties and, overall, these make tough, energy-absorbing structures, thanks to the thermoplastic.”

CFRP catenary for lower-cost electric railways

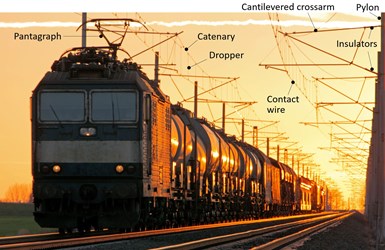

Fig. 2. Traditional OHLE

Overhead line equipment (OHLE) for electric railways have traditionally used steel catenary wire, which requires pylons every 25 meters and numerous steel cable droppers to support the current-carrying copper contact wire. Source | CW

This thermoplastic epoxy’s dual nature is exemplified in an overhead line equipment (OHLE) system developed by Cecence using a CFRP catenary made with K_Rod. The catenary and the current-carrying contact wire are the two main wires in an electric railway’s OHLE (Fig. 2). Electricity is delivered to a train’s locomotive through a pantagraph, which extends from the top of the locomotive to press against the contact wire. “The catenary acts like a suspension bridge between pylons (masts, poles), which are spaced every 25 meters along the tracks,” Orange explains. The copper contact wire is suspended from the catenary by vertical dropper wires or droppers, much like the roadway is supported from cables in a suspension bridge.

Compact CFRP catenary

In its cost-effective, composites-based COHLE system, Cecence thermoplastic epoxy is used to produce a CFRP catenary wire that sits only 70 millimeters above the copper contact wire, attached using 3D-printed PLA clips for droppers. Source | Cecence

“By using a K_Rod tension cable as the catenary, it can sit only 70 millimeters above the copper contact wire,” Orange points out (Fig. 3). “The whole system is more compact with much lower visual impact on the environment.” Current OHLE systems use steel catenary cables, which change length with change in temperature. “In the summer, they extend by as much as 400 millimeters per kilometer,” he notes. To counteract this sagging in the lines, concrete counterweights on pulleys are installed as an auto-tensioning system, but add to overall cost.

“The weight of the steel line and its sag profile are also why so many poles are needed,” Orange notes. “Our CFRP cable changes length by only 7 millimeters per kilometer in the summer because the negligible thermal expansion of carbon fiber creates a thermally stable composite. It is also 80 percent lighter than steel cable, doesn’t sag and enables spacing the pylons 50 meters apart, which halves the number of pylons required.” This enables further cost savings because for every pylon there is a cantilevered crossarm, supported by a stay wire.

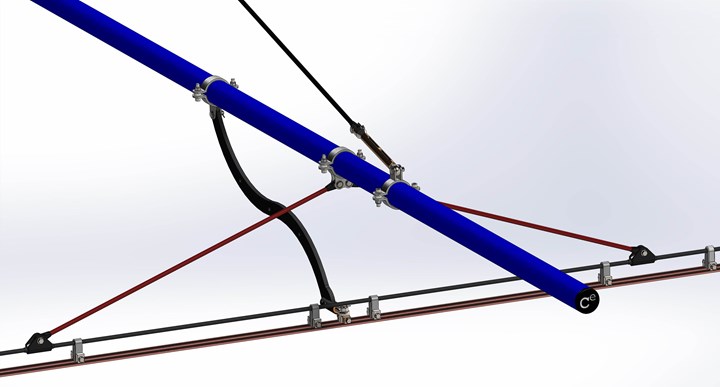

Non-conductive, cantilevered crossarm

The Cecence-developed COHLE does not require insulators because it uses a non-conductive glass fiber/TP epoxy crossarm (shown in blue) which is cantilevered from a glass-fiber/epoxy pylon pole and from which the CFRP catenary is supported. Source | Cecence

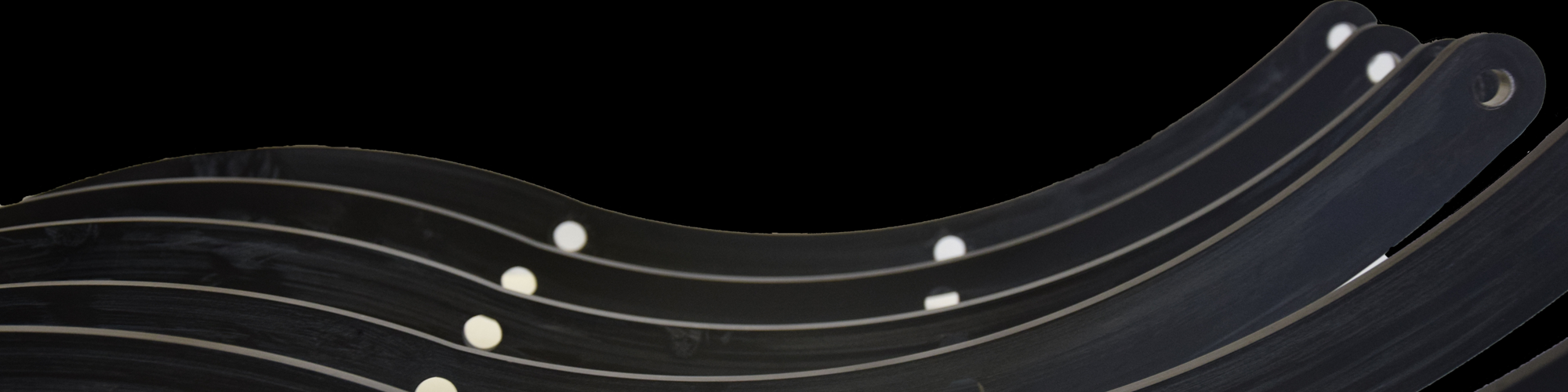

Remaining COHLE components

The COHLE that Cecence has developed is more compact and less costly than metal OHLE due to high-performance, thermoplastic epoxy composite components, including glass fiber-reinforced cantilevered crossarms (top) and curved

registration arms (center), which provide a vertical

support and separation between the crossarm and catenary wire (see COHLE rendering above).

Plastic-coated aramid fiber cables (bottom) serve as stay wires from the pylon pole to the cantilevered crossarm and also from the crossarm to the CFRP catenary. Source | Cecence

Further, conventional OHLE systems use all-metal components, which requires adding insulators to prevent unwanted conduction of the electric current. “The Cecence COHLE doesn’t need all of the insulators because it uses nonconductive glass fiber (GF) composite poles and crossarms with nonconductive composite stay cables,” Orange explains. “We also use intermediate droppers made from 3D-printed polylactic acid (PLA). Unlike a metal system, the poles do not need regular painting and the corrosion-resistant composites require less maintenance.”

“The thermoplastic epoxy plays a key role in the CFRP catenary,” he continues. “Cecence uses it in both the carbon fiber K_Rod core and in the overbraided GF composite jacket. The result is a lightweight, high-strength, insulated cable that is coilable and bonds well when glued into a socket, resolving the normally tricky termination issue for carbon fiber composite cables. Thanks to the amazing load transfer from the core into the socket through the overbraid, we don’t need a huge socket length and this system is easy, so it’s practical to install in the field by railway technicians.”

Installed for testing

Cecence COHLE prototype components were installed at a test track in 2019 and await only electrification via contact wires before performance testing can begin. Source | Cecence

Even though the CFRP cable costs three times that of a steel catenary, the overall system cost is reduced from £512,000 to £413,000 per kilometer, says Orange. These costs, calculated with multinational engineering and infrastructure firm Atkins (London, U.K.), include operations/maintenance savings of £400,000 to £3.4 million per kilometer over the system lifetime.

“Cecence delivered the prototype components in May 2019,” says Orange, “and our development partners had scheduled to put up the electric lines by February 2020, but that was delayed due to COVID-19. The whole system was displayed at the Advanced Engineering Show in 2019 and won the Composites UK Innovation Award.”

Further K_Series applications and development

Beyond the OHLE application, Cecence is pursuing other opportunities to apply its K_Series products. “Cecence has also worked on projects where the K_Rod cables were used as anchors for a stone cliff face in a construction project in Switzerland,” says Orange. “Our project partners were to drill 80-meter deep holes into the rock, insert the CFRP cables and then fill with concrete. There were some amazing test results, but the academic partner never connected with industry to develop the project beyond lab scale. We are pursuing other demonstrations, however this system is corrosion-proof and provides good load transfer. It could also be applied as ground anchors for various construction systems, such as hurricane-proof buildings.”

Videos on YouTube and the Cecence website demonstrate the thermoformability of its K_Plate products. “There have also been discussions to explore applications for variable geometry/morphing airfoils with a U.K. aerospace company,” says Orange. Cecence demonstrated a cost-effective automotive material using K_Chip made with chopped composite tows as a hybrid CF/GF/thermoplastic epoxy material, maintaining a 2:1 ratio of carbon to glass, confirmed via testing. .”

The company has also developed a high-temperature K_Series with a Tg of 250-300°C that processes at 360-400°C. “This was used for an automotive manufacturer that wanted the CFRP parts to survive their 180°C E-Coat painting process,” says Orange. “We also have the K-FR material, which can pass aircraft FST vertical burn, heat release and smoke toxicity requirements, and we are looking at how to assist with vibration damping for reducing aircraft cabin noise. We can tune the thermoplastic and add elastomeric material layers to achieve significant noise reduction.”

Samantha Bunyan, the third Cecence founder and its head of industry engagement, points out that recyclability is also a key area of development. Cecence is part of the ReDisCoveR Composites consortium, operated by the National Composites Centre (Bristol, U.K.). It was established in April 2019 and is pursuing 24 projects along the four streams: recycling, disassembly, circular materials and reuse. “Within these projects, we are looking at disassembly of components and demonstrating the real recyclability of thermoplastic composites,” says Bunyan. “The industry is finally being forced to prove the recyclability it has claimed for many years. Cecence sees the benefits of being able to recycle K_Series thermoplastic epoxy products, but it also has to demonstrate the processes and economic feasibility for this.”

“We believe there is much more room for sustainable composites in mass transportation, including aircraft interiors, seating and rail applications,” says Orange, adding that Cecence is not just a partner in development but also in manufacturing. “We have made 2,500 composite seatbacks for A320-type aircraft to date and were on track to produce the lightest and thinnest seatbacks in the industry before the outbreak of COVID-19. Scrap from composite seats can be re-used in footrests and armrests. Recyclate can also be used in other auxiliary parts currently use virgin plastics. All of this can help to lower fossil fuel consumption and emissions as well as facilitate electrification and increase sustainability.”

In composites, notes Samantha Bunyan, “sustainability is threefold: materials, processing (fast and low-energy) and supply chain. We are disrupting all of these, working with innovators from all over the world who don’t get seen because most people look only at the big companies. The world needs new solutions that work for industry. This is what Cecence does.”

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Withstanding fire without the weight

New composites meet stringent fire requirements while lightweighting ships, rail cars and battery boxes for electric cars and planes.

Read MoreYachtbuilding Composites: Rigged for Success

Carbon composite cabling in several forms races ahead of dry fibers and stainless steel in sailboat rigging.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)