Aimplas-led project develops thermoplastic prototypes

The RECONTRANS project adapts Arkema’s Elium thermoplastic resin for car, truck and rail applications.

Source | Aimplas

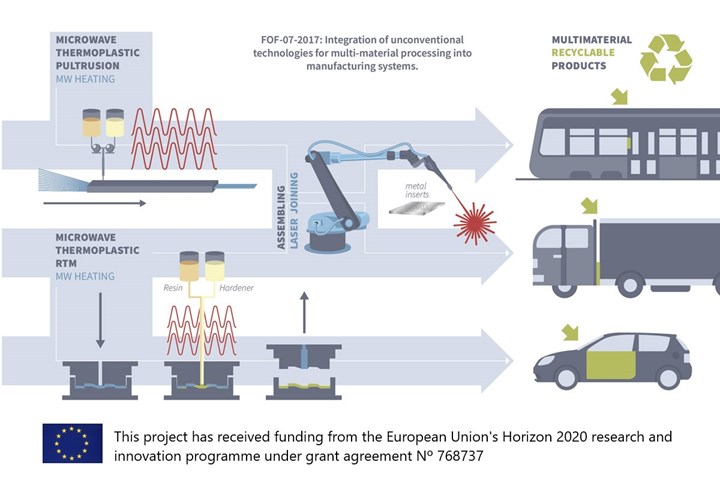

Aimplas, the Plastics Technology Centre (Valencia, Spain), reported on June 9 that its EU-funded RECONTRANS project — developing multi-material thermoplastic parts as a light weight, cost-effective solution for sustainable vehicle design — obtained its first three prototype samples in the automotive, truck and rail sectors.The three demo samples include the door of a car, the rear suspension of a truck cab and the interior panel of a train coach.

Aimplas says the three samples obtained were manufactured with Arkema’s (Colombes, France) Elium thermoplastic resin, which has been adapted for microwave curing and welding. Aimplas manufactured the automotive and truck demonstrators using resin transfer molding (RTM) and pultrusion to reduce fabrication time and energy consumption. The hybrid welding process was used for metal-polymer joining of the truck and train prototypes to reduce raw material waste and improve the standardization and automation of the production process. The institute also notes a production line monitoring system kept tabs on the entire process.

Aimplas says progress in the project’s 30th month shows that, following the manufacture of the first prototypes, significant cost and energy consumption reduction was achieved compared to conventional composites, and that it provides a feasible process for recycling and for processing recycled thermoplastic composites.

The RECONTRANS project, started in October 2017, will end in October 2021. With a total of 13 partners from seven countries taking part, Aimplas says the developments carried out in this project will be applied to other sectors as well.

Related Content

-

Industrial equipment manufacturer expands global footprint, reaches into new markets

India-based CW Top Shops honoree EPP Composites reflects on a recently successful vertical filament winding application and new pultruded FRP rebar capabilities, as well as future opportunities.

-

FST-rated thermoset resin with rapid, tunable cure is designed for infusion

CAMX 2023: The nonhalogenated Harp Rapid resin system presented by Trimer Technologies achieves a low-temperature, tunable cure while attaining high mechanical properties, demonstrating its effectiveness in aerospace applications.

-

Exel Composites supplies fiberglass profiles for Foton electric buses

Partnership with Chinese automotive manufacturer will see the implementation of pultruded profiles in various bus models, backed by weight savings, complex geometries and long life.