Filament Winding

Composite leaf springs: Saving weight in production

Fast-reacting resins and speedier processes are making economical volume manufacturing possible.

Read MoreInspection: 30-year-old fiberglass pipeline stands test of time

Examined after three decades in service (half its predicted service life), this filament wound fiberglass pipe showed no signs of degradation.

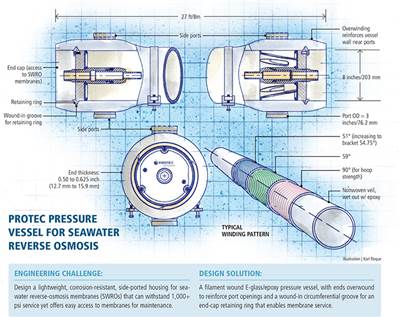

Read MoreDesigning pressure vessels for seawater desalination plants

Safe high-pressure service challenges manufacturers of composite pressure vessels.

Read MorePipes vs. vessels

CT editor-in-chief Jeff Sloan notes the value of composite pressure vessel standards in the growing market for seawater desalination.

Read MoreSewer system: Corrosion protection for buried odor-control ductwork

ECS Environmental Solutions (Belton, Texas) was contracted to provide odor control equipment and relied on Vipel vinyl ester resin from AOC Resins (Collierville, Tenn.) for more than 1,000 ft/305m of fiberglass ductwork and accessories.

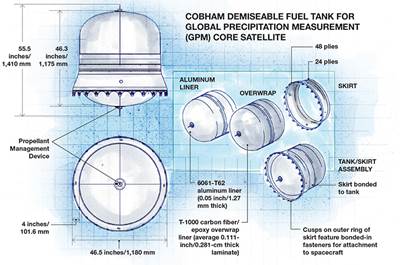

Read MoreSpace mission maximized via minimized survivability

CFRP design and manufacturing flexibility prove key in first spacecraft fuel tank designed to disintegrate upon reentry for improved mission efficiency and debris mitigation.

Read MoreComposites slake the world's thirst

As the global thirst for drinkable water increases, the composites industry is drinking in the tremendous possibilities in seawater desalination.

Read MoreMaking continuous composite pipes

A description of the continuous filament winding process.

Read MoreThe first commercial Type V composite pressure vessel

Composites Technology Development's first commercial tank in the Type V category presages growth of filament winding in storage of compressed gases.

Read MorePressure vessel tank types

Pressure vessels have been classified in four categories, based on their construction. Each type has assets and liabilities.

Read More

.jpg;maxWidth=300;quality=90)