Infusion

Poly Glass reports manufacture of 60-foot infused monohull boat in India

The ZenCat commercial vessel features a 60-foot vacuum-infused FRP hull enabling weight reduction and fuel savings.

Read MoreComposite aerostructures in the emerging urban air mobility market

In the not too distant future, point-to-point, limited-distance, piloted and autonomous air travel for people and cargo will be the norm. Composites will make it possible.

Read MoreComposites Academy launches online training with hands-on exercises

Composites Expert and Institut de Soudure partner to provide interactive advanced composites training to students and professionals worldwide.

WatchUpdate: Lower wing skin, Wing of Tomorrow

Airbus is evaluating several advanced composites technologies as part of its Wing of Tomorrow program. Among these is liquid resin infusion of the lower wing skin, being developed by Spirit AeroSystems.

WatchCovestro machine developed for direct infusion of polyurethane rotor blades

Covestro’s tailor-made Baulé machine enabled production of a 64.2-meter-long polyurethane turbine blade.

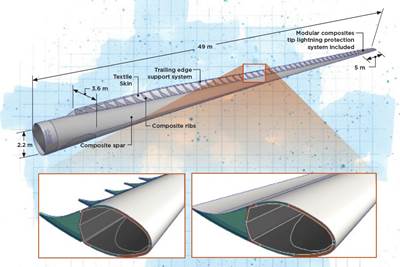

Read MoreReimagining wind blade design

Wind turbine blade architecture is so well established that it’s difficult to imagine there might be a better alternative. ACT Blade’s skeleton-based design is a step in that direction.

Read MoreWebinar presentation: Next-Generation Composites Materials and Processes (July 2020)

CompositesWorld hosted on July 28, 2020, a webinar titled, “Next-Generation Composite Materials and Processes.” If you missed the live webinar, you can watch the recording or download a PDF of the presentation.

Read MoreComposites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

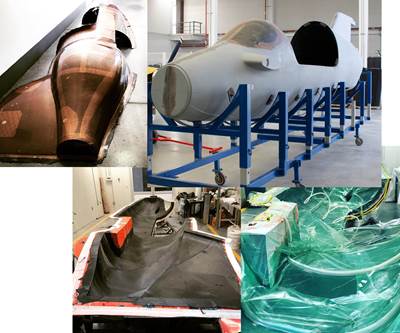

Read MoreFirst all-CFRP fuselage in Mexico

UNAQ and RHEM Composites help produce body of third prototype for Oaxaca Aerospace’s Pegasus P-400T.

Read MoreNo business case for reteaching robots

DLR Center for Lightweight Production Technology has developed an AI-equipped work cell where collaborative robots can switch from producing composite rear pressure bulkheads to fuselage panels without requiring reprogramming or retraining.

Watch

.jpg;maxWidth=300;quality=90)