Infusion

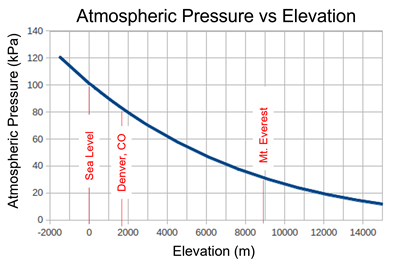

Avoiding the pitfalls of vacuum infusion processing

Understand the fundamentals of vacuum infusion processing (VIP), including pressure, permeability and race tracking, to prevent issues and produce consistent results.

Read MoreComposite-metal joining, braided preforms enable next-generation aircraft design

Collins Aerospace invests in new joining, preforming and infusion techniques to target aircraft design needs for reduced weight and lower-cost manufacture.

WatchCAMX 2021 exhibit preview: Gustav Gerster GmbH & Co. KG

Gustav Gerster’s TechTex corner reinforcements and resin distribution tape optimize the structure of composite components.

Read MoreCAMX 2021: Cimbar Performance Materials

Cimbar Performance Materials’ halogen-free ATH solution for thermoset applications reduces resin costs in formulation, provides better wetout and faster line speeds and improves mold flow.

Read MoreCAMX 2021 exhibit preview: Scott Bader

Scott Bader displays its Crestabond and Crestomer structural adhesives, Crestafix bonding pastes, Crestapol urethane acrylate resins and Crestamould tooling system.

Read MoreComposites Integration expands Metyx partnership, appoints as U.S. distributor

Strengthened partnership expands RTM, infusion and technical textile offerings to U.S. markets.

Read MoreFine Hulls brings bold boat design with Diab sandwich composites

The pleasure yacht is entirely made from Diab’s Divinycell foam sandwich core using a vacuum infusion process for excellent stiffness, strength and light weight.

Read MoreCurve Works reaches milestone for modular builds of composite shell structures

Approach reduces cost by 40%, lead-time by 50% and material use by >70% compared to manufacturing in large, one-off mold.

Read MoreIn-mold coating offers high-performance finishing for epoxy-infused composites

ODG Composites’ Element Xtreme is a lightweight, long-lasting protective and aesthetic coating suitable for a range of industrial and commercial applications.

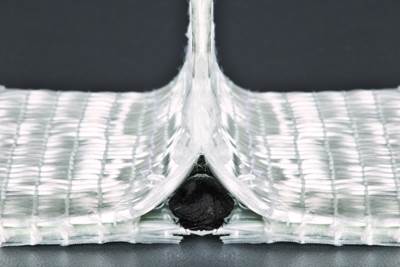

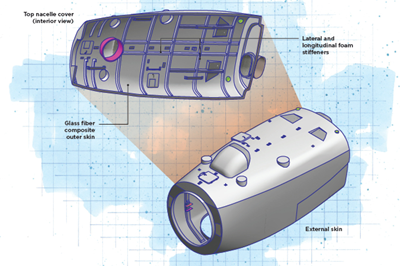

WatchOptimizing a wind turbine nacelle cover to meet LCOE demand

Suzlon Group redesigned a composite nacelle cover with in-situ molded stiffeners to reduce manufacturing and material costs while maximizing part performance.

Read More

.jpg;maxWidth=300;quality=90)