No business case for reteaching robots

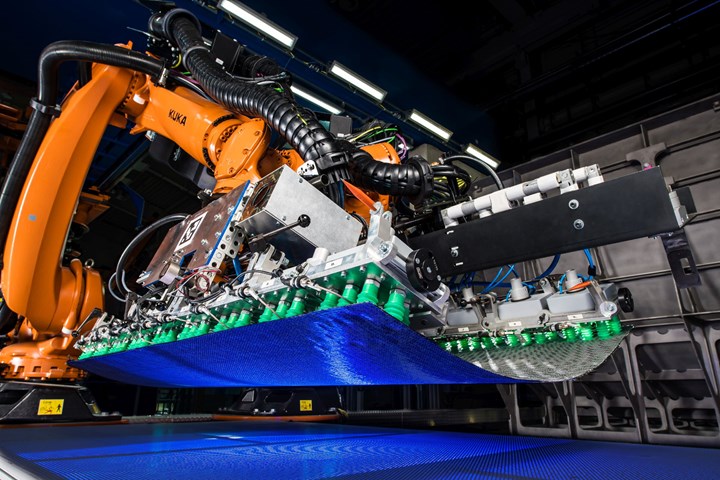

DLR Center for Lightweight Production Technology has developed an AI-equipped work cell where collaborative robots can switch from producing composite rear pressure bulkheads to fuselage panels without requiring reprogramming or retraining.

This online sidebar for the July 2020 article, “Composites 4.0: Digital transformation, adaptive production, new paradigms” will give more visuals and details regarding the development of an AI-equipped work cell where collaborative robots can switch from producing composite rear pressure bulkheads to fuselage panels without requiring reprogramming or retraining.

As explained in the feature article:

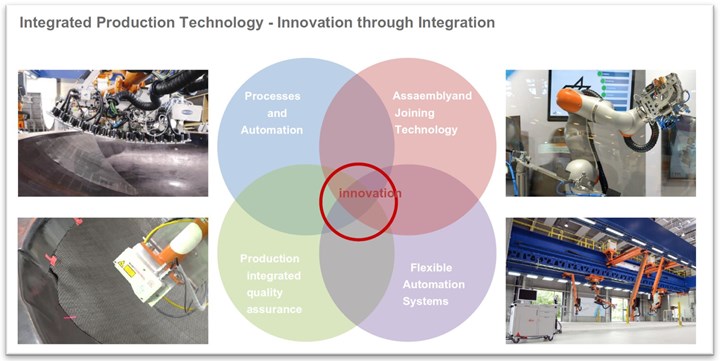

“Composites 4.0 is not just using robots,” asserts Dr. Michael Kupke, head of the Center for Lightweight Production Technology (ZLP, Augsburg, Germany).

“It is the technology that ensures you don’t have to teach the robots, because there is no business case for that. Composites 4.0 is more than just increasing efficiency and cutting cost. It is a change in how companies think about and approach production that will determine which companies survive and which do not.”

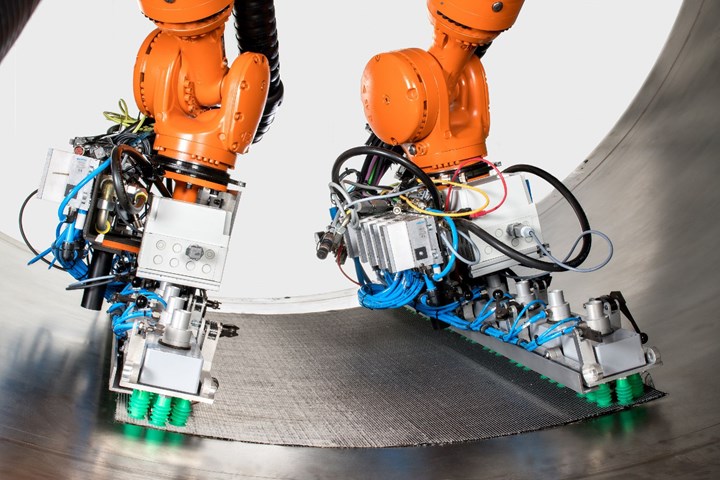

ZLP’s autonomous work cell uses an AI-driven work cell to lay up a composite rear pressure bulkhead (bottom) and a composite fuselage panel (top), switching between without reteaching the collaborative robots. Source | ZLP Augsburg and DLR Institute of Structures and Design

Robot programming

“Typically, there are three approaches to programming robots,” explains Dr. Lars Larsen, head of assembly and joining technologies at ZLP Augsburg. These include:

- Textual — programming codes (code, test, rewrite code)

- Teach-in — interactive with robot via tablet computer

- Offline — with simulation, using a digital representation of the robot cell.

“In this last method, you move the robots but you immediately trial-and-error, so it is much faster than the textual method,” he notes. “You can move the robot manually in the simulation in parallel without tying up robots or causing damage from collisions, etc. But there is no intelligent behavior of the robot in any of these methods. The robots must be taught.”

“So, there is no automated process development; the automation is not fully automated,” emphasizes Florian Krebs, Larsen’s colleague in the Protec NSR and Factory of the Future projects and team leader for flexible automation. These projects, however, did demonstrate automating the automation. “What you see in the YouTube video [below] are two robots working to grip, transport, layup and cut pieces of carbon fiber fabric into tooling. Both robots must place each cut piece in the precise position and orientation as indicated in the digital design [CAD file]. If the cut piece is just a little out of either position or orientation, then the part is not produced as planned.”

Intelligent, modular grippers

Krebs stresses that simply placing the cut pieces and inspecting for accuracy is not an autonomous system. To achieve that, the system must sense and use data to make intelligent decisions. “There is data being generated in the gripper and in the robot – position, speed, what actions have been completed, visual inspection, etc. — you have all of this information. If you learn how to use this information, you can improve your production. So, now you can transport and layup in the tooling, mirroring the component as-built in the digital representation (digital twin). For example, if there is a wrinkle in the placed piece, what do we do?”

Two types of gripper systems

Intelligent modular gripper system for flexible layup including camera system, which is not visible (top) and one of two tandem grippers for layup of large cut pieces up to 6m x 1.2m (bottom). Source | ZLP Augsburg and DLR Institute of Structures and Design (Stuttgart)

“We use detection of each cut piece position and orientation,” says Krebs. “For this, you need a sensor, which in this case, is a camera. The work cell uses the CATIA CAD model as a single source of truth, a defined process chain and the camera plus other sensors to plan the next steps based on AI-algorithms . From these, it can infer which cut piece should come next and looks for that on the table. For example, an aerospace part may consist of 100 or more differently contoured cut pieces on the table.”

“Once it locates the correct cut piece it will determine how to grip it,” he continues. “The system has the ability to autonomously adapt each robot’s grippers to the necessary configuration. It also knows where to put the cut piece in the tooling (per the CATIA model) and the start-end path in between all process steps. Usually, this path is taught by a human. But in our system, this path is planned automatically and thus collision-free.”

“The robot looks for the cut piece, adapts the gripper, makes a path plan and moves without collision.” This includes avoiding collisions with the other robot or the molding tool, but also without crashing the cut piece into anything. “So, you also need a representation of the cut piece geometry for this,” says Kupke. “Lars developed/adapted the algorithms here. The gripper must also drape the cut piece using data from the sensors embedded in its gripping modules .” The gripper is a modular system with more than 120 separately controlled gripper modules . “[During draping] some will adust gripping force to avoid wrinkles, but to do this, you must understand how your material behaves, where the cut piece is moving and how far. Another camera and the gripper’s embedded sensors provide the optical measurement for this which then enables the gripper to adapt its modules’ parameters to prevent wrinkles.

A truly autonomous system

“The process is much clearer in the video,” says Kupke. “You see an automated production of a part but the Composites 4.0 operating underneath that makes it possible is mostly invisible. Composites 4.0 is the foundation for such an automated production system. This is the key to Composites 4.0. It’s not to use robots, because you then must teach the robots thousands of things. You need to ensure that you don’t teach the robots because there is no business case for that. Composites 4.0 will lower the barrier for automated processes everywhere. It will improve reproducibility. In aerospace, we have this hurdle of making the business case for composites especially in lower part count programs.” (See “Revolutionizing the composites cost paradigm: Part 1 and Part 2”)

“This is why we’re working on this,” he continues. “It looks so nice when robots work on parts but that’s not what is important. What is important is to change the business case.”

But this requires a change in mindset. “If you are just creating an automated system to do a specific task, then you must search for more tasks to do with only this platform in order to justify the investment and expense,” says Krebs. “You must open up to not just task-specific machines but instead an automation platform. So, this is still a machine, but one that is reconfigurable to multiple tasks and parts. Then, this opens the road to reap the benefits of automation. The more flexible your automation platform is, the sooner you get a return on investment (ROI) for it. It is hard to justify automation for just one part/program. But if you can reconfigure it with almost no set up at all, now you have a business solution.”

See the main article for more discussion on the details of the autonomous collaborative robotic work cell that DLR developed.

Integrated NDT

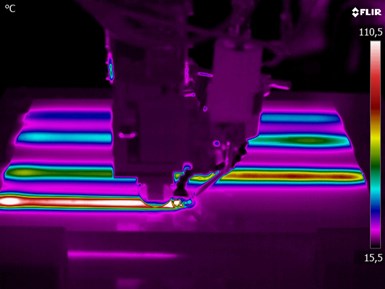

Thermography uses infrared cameras to monitor temperature in processes such as induction welding thermoplastic composites (shown here) but also measures temperature response in a structure to indicate areas with anomalies or defects.

Source | CETMA

“What we have shown on the dry textile rear pressure bulkhead at JEC 2019is how we can integrate NDT (nondestructive testing) steps into the production process,” says Kupke. “Ideally, you would have a way to show that you know you have produced a high-quality part. In that case, you don’t need to perform NDT. But we’re not to that point yet. So, the intermediate step, for now, is how to better integrate NDT measurements into the production process, such as integrated thermography.”

“The current practice is to make a thermography measurement and then use the thermography system software to locate this data relevant to the part,” he explains. “Usually, you have to do this manually; it’s not automated. But DLR is developing technology to automate this process.”

Kupke notes that it is already possible to automatically merge ultrasonic testing (UT) C-scan data relative to the part. “However, themography is an easier, better method to integrate into the production inline versus water-based UT.”

“So, now we have merged NDT with the CATIA CAD file,” he continues. “If you have this and all production data, then you can use a laser projector to project your NDT findings [e.g., defects] onto your part. As a composite parts supplier, you can also use this data to send to Boeing or Airbus: ‘I have found this NDT result on part #123 at this location. Let’s discuss this.’ Today, someone goes to the part and marks the NDT findings with chalk on the part. If you have all of the data available, however, then you can use this data anywhere to do what you want. You can use AR (augmented reality) to project key information on the part for manual remediation or you can do like ZAero and perform simulation to choose whether to keep the defect or not.”

From the Protec NSR/Factory of the Future project, Kupke’s team refined using fiber angle measurement with a laser device to follow the edges of the cut pieces of carbon fiber fabric to verify correct location and fiber orientation. “By combined infrared thermography, fiber angle measurement and the cut piece versus CAD via the laser device, you have all you need for autonomous layup and preforming.”

Source | ZLP Augsburg and DLR Institute of Structures and Design (Stuttgart)

What remains to be done?

“We have showed a lot of different issues that have a common solution in Industry 4.0, big data and Artificial Intelligence, but we aren’t there yet,” says Krebs. “When we are there depends on how you define “there”. Machines will become more autonomous and more flexible. If you have all of the processes and robotics, then you just need more software development but also the mindset needs to change.”

“Instead of thinking we are at Stage A but when will we be at stage B,” adds Kupke, “it is better to think of progress as moving in the right direction to achieve the goals we seek, for example wider access and use of composites. So, there is no point B, but instead a continuous improvement toward these goals.”

Krebs gives an example, “Automation in the automotive industry is very widespread and advanced, but reconfigurability hasn’t been a strong driver because they have had high volume. Now, however, they face the same issues as aerospace because their market is being fragmented. So, everyone is facing a paradigm shift.”

“Autonomous means the production system can adapt,” says Krebs. “This is key for future agile production. For autonomy, you need sensors providing data, automation technology and the capability to reason how your data affects the environment – in other words: AI. This flexible use of production equipment on the shop floor is the coming future: less parts of each kind, more variation.” He notes that higher degrees of automation enable higher flexibility, “but only if the next step is to automate the automation so that much less effort is spent commissioning and programming robots. Thus, you increase overall equipment efficiency. This is our next step at DLR.”

“Composites 4.0 is a specific example of the challenges in Industry 4.0,” says Kupke. “At DLR, we have a special perspective; we try to develop generic solutions — meaning most applicable to many processes, parts and challenges — and adapt them to problems in composites. A good example is a robotic competition held last year. The challenge was to pick up a Spanish fan, open it, close it and put it back down again. We chose our autonomous composites work cell to do this. We used our system and achieved the challenge in only a few days, while our best competitors had been planning for months. this shows how flexible our process truly is.”

And this, then, is showing what will become the future. Those who can achieve Composites 4.0 will respond in days (or hours), not months when the part, program, market and/or world changes. This is why what Composites 4.0 is really about is not just a matter of efficiency, it will decide who survives and who does not.

Related Content

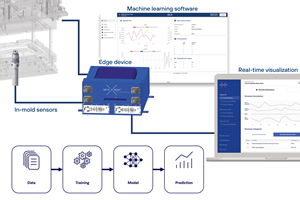

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Read MoreUltra high-rate composite deposition system trials to surpass layup targets

The NCC, alongside partners Loop Technology, Coriolis and Güdel, are on track to deliver dry fiber deposition rates exceeding 350 kilograms/hour, seven times more than standard aerospace rates.

Read MoreModular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

Read MoreHow AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More