Infusion

Team-built bus body bests all

OEM meets tight development schedule on superlight multipart molded shell to offset propulsion system weight in fuel cell-powered transit bus.

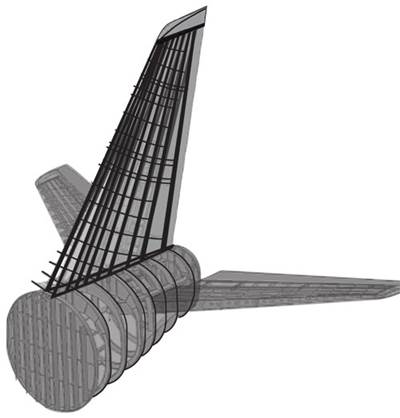

Read MoreCost- and time-saving preform process used for propeller spinner

Carbon fiber/epoxy spinner uses pulp slurry preforming process combined with vacuum infusion molding.

Read MoreInside R and D: A-VaRTM takes flight in Japan

Tests show out-of-autoclave process can reduce costs on new regional jet.

Read MoreComposites take the hit in U.S. Navy patrol boat

New carbon/Kevlar composite hull and deck provide impact-absorbing solution to crew injury problems caused by severe vertical acceleration of previous high-speed, all-metal patrol boat.

Read MoreFormulating challenge: Creating better epoxies for vacuum-infused aerospace parts

More attention is being focused on fabricating processes for aircraft structures that can save time and money and improve efficiency while yielding high-quality parts. Historically, nearly all aircraft designers have assumed autoclave cure as the norm, despite the well-documented cost and time advantages of

Read MoreInside Analysis: Simulating VARTM for better infusion

A resin flow simulation tool is helping to optimize liquid molding of aerospace parts.

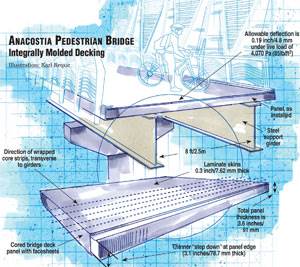

Read MoreEngineering Insights: Pedestrian Bridge Makes Case for Composites

Infusion molded deck incorporates high-performance core, which facilitates fast processing.

Read MoreInside Manufacturing: 45,000 Fan Ducts Per Year from RTM

Unique tooling technology optimizes closed molding process efficiency for volume production of industrial part.

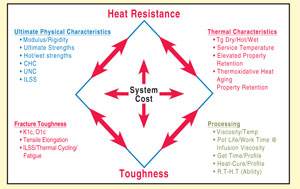

Read MoreMarket Trends: Composites Affordability Initiative, Part II

The Air Force Research Laboratory's Dr. John Russell continues an outline the U.S. Department of Defense Composites Affordability Initiative. Part II of a two-part series.

Read MoreMarket Trends: The Composites Affordability Initiative, Part I

The Air Force Research Laboratory's Dr. John Russell outlines the U.S. Department of Defense Composites Affordability Initiative. Part I of a two-part series.

Read More

.jpg;maxWidth=300;quality=90)