Infusion

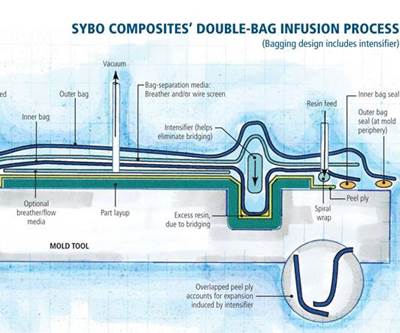

Double-bag infusion: Thickness gradient and pressure

Cliff Walker (Vacmobiles, Auckland, New Zealand), explains how the large pressure changes during infusion result in laminate compression and thickness variations across the part.

Read MoreAbsolute vacuum gauge

The following is an excerpt from Issue 12 of The Composites Letter, published by www.vacmobiles.com (reposted here by permission) that outlines the importance of using an absolute vacuum gauge to measure pressure levels during double-bad infusion:“Often called a precision vacuum gauge, an absolute gauge actually works the opposite way to a conventional dial type vacuum gauge.

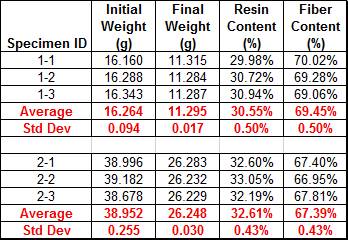

Read MoreDouble-bag infusion: 70% fiber volume?

A double vacuum-bag system and tight process control enable repeatable fiber volumes of 60 to 70 percent and improves consistency of infused laminates.

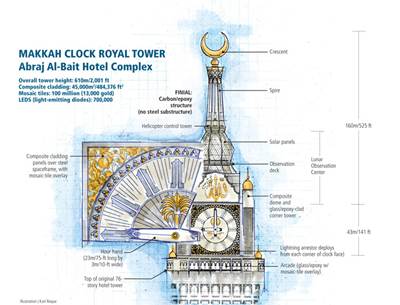

Read MoreBesting Big Ben: A Marvel in Makkah

Composite design makes possible the world’s largest clock and tallest clock tower.

Read MoreThird-party tests support claims for crosslinking spray adhesive

Aerospace manufacturers that adopt vacuum infusion processes are discovering what processors of boat hulls and wind turbine blades already know: Placement of multiple plies of slippery dry fiber reinforcements in molds with vertical sides or tight radii is problematic.

Read MoreA400M cargo door: Out of the autoclave

This structural military airframe part is the largest made to date via the vacuum-assisted resin infusion process.

Read MoreDDG-1000 Zumwalt: Stealth warship

U.S. Navy navigates radar transparency, cost and weight challenges with composite superstructure design.

Read MoreNew infusion regime for superthick laminates

Innovative initiator chemistry yields long flow time, cure on demand and exotherm control for large, thick parts.

Read More

.jpg;maxWidth=300;quality=90)